Yamaha RD350: A Step Further

Barry Watkins

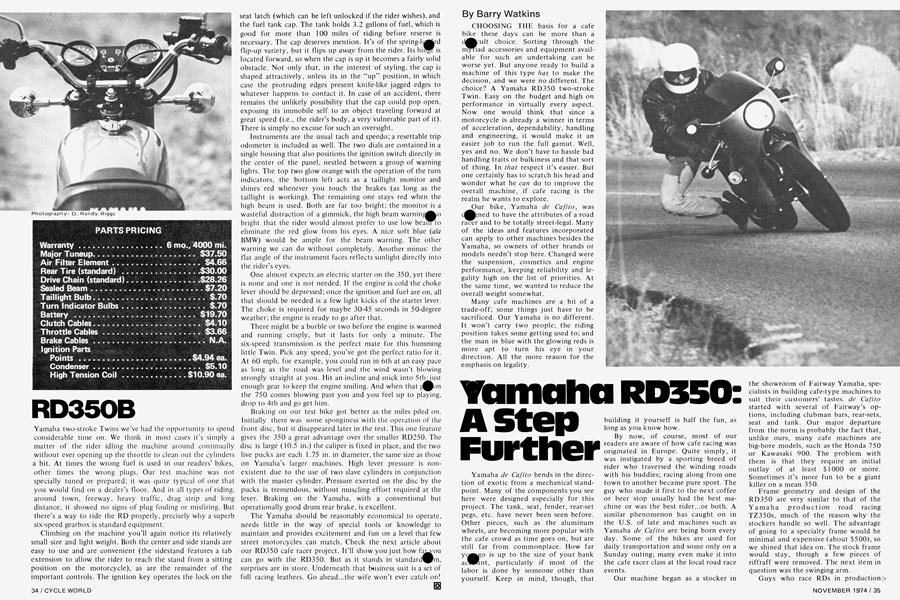

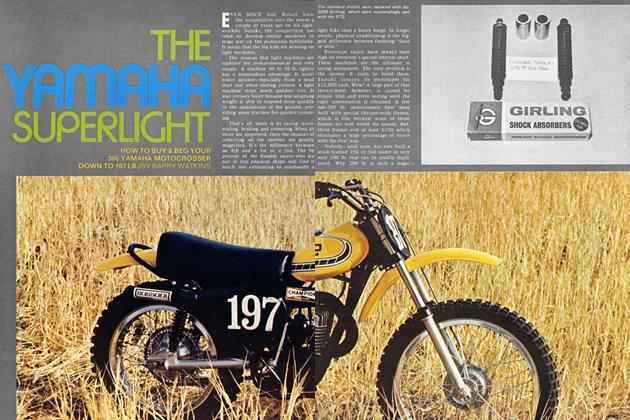

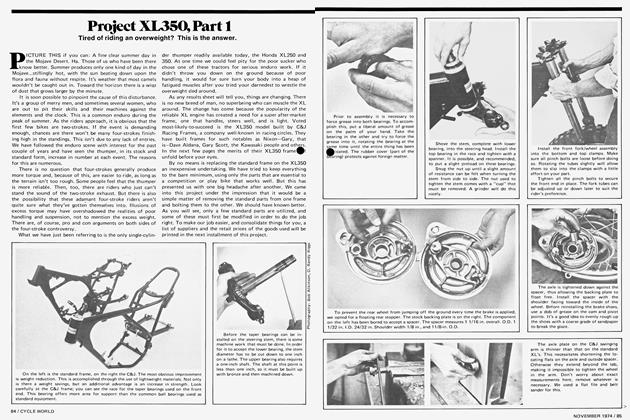

CHOOSING THE basis for a cafe bike these days can be more than a dificult choice. Sorting through the myriad accessories and equipment available for such an undertaking can be worse yet. But anyone ready to build a machine of this type has to make the decision, and we were no different. The choice? A Yamaha RD350 two-stroke Twin. Easy on the budget and high on performance in virtually every aspect. Now one would think that since a motorcycle is already a winner in terms of acceleration, dependability, handling and engineering, it would make it an easier job to run the full gamut. Well, yes and no. We don’t have to hassle bad handling traits or bulkiness and that sort of thing. In that respect it’s easier. But one certainly has to scratch his head and wonder what he can do to improve the overall machine, if cafe racing is the realm he wants to explore.

Our bike, Yamaha de Cafito, was cj^^gned to have the attributes of a road racer and to be totally street-legal. Many of the ideas and features incorporated can apply to other machines besides the Yamaha, so owners of other brands or models needn’t stop here. Changed were the suspension, cosmetics and engine performance, keeping reliability and legality high on the list of priorities. At the same time, we wanted to reduce the overall weight somewhat.

Many cafe machines are a bit of a trade-off; some things just have to be sacrificed. Our Yamaha is no different. It won’t carry two people; the riding position takes some getting used to; and the man in blue with the glowing reds is more apt to turn his eye in your direction. All the more reason for the emphasis on legality.

Yamaha de Cafito bends in the direction of exotic from a mechanical standpoint. Many of the components you see here were designed especially for this project. The tank, seat, fender, rear-set pegs, etc. have never been seen before. Other pieces, such as the aluminum wheels, are becoming more popular with the cafe crowd as time goes on, but are still far from commonplace. How far yc^^o is up to the size of your bank aclRnt, particularly if most of the labor is done by someone other than yourself. Keep in mind, though, that building it yourself is half the fun, as long as you know how.

By now, of course, most of our readers are aware of how cafe racing was originated in Europe. Quite simply, it was instigated by a sporting breed of rider who traversed the winding roads with his buddies; racing along from one town to another became pure sport. The guy who made it first to the next coffee or beer stop usually had the best machine or was the best rider...or both. A similar phenomenon has caught on in the U.S. of late and machines such as Yamaha de Cafito are being born every day. Some of the bikes are used for daily transportation and some only on a Sunday outing; many even make it into the cafe racer class at the local road race events.

Our machine began as a stocker in

the showroom of Fairway Yamaha, specialists in building cafe-type machines to suit their customers’ tastes, de Cafito started with several of Fairway’s options, including clubman bars, rear-sets, seat and tank. Our major departure from the norm is probably the fact that, unlike ours, many cafe machines are big-bore models, such as the Honda 750 or Kawasaki 900. The problem with them is that they require an initial outlay of at least $1000 or more. Sometimes it’s more fun to be a giant killer on a mean 350.

Frame geometry and design of the RD350 are very similar to that of the Yamaha production road racing TZ350s, much of the reason why the stockers handle so well. The advantage of going to a specialty frame would be minimal and expensive (about $500), so we shined that idea on. The stock frame would stay, though a few pieces of riffraff were removed. The next item in question was the swinging arm.

Guys who race RDs in production class events have complained a bit about swinging arm flex, but only under pretty tough conditions. One has a good choice in this area, because there are several ways you can turn. You can get along quite well with the standard arm unless you’re an exceptional rider, then you might want to try any one of the following: the standard TZ350 unit

from the road racer, a Harry Hunt swinging arm, or a Don Vesco unit. To use any of these latter components, the axle holes and axle adjusters on the stock machine must be shimmed to fit. Also, the shock mounting has to be changed to a more vertical position. We decided to go ahead and try the stock unit since most of the machine’s intended use would be on the street. That way it wouldn’t be subjected as much to the rigors of competition.

Tank, seat and fender have their own unique style and were designed by Harold Hannemann of General Engineered Products. The tank features an aircraft type fuel filler lid that is completely flush with the top of the tank. Constructed of hand-laid fiberglass for strength, the tank is available in different lengths for different applications. The model shown holds four gallons of fuel; the stock petcock is retained. The unit was designed narrow at the front to allow ample clearance for the low bars. This way the machine can be maneuvered around as nimbly as a stocker; most cafe machines have a problem in this respect.

A new seat and tail section replace stock components and do more than look good. The seat itself is one piece, amply padded with high-quality upholstery. Utilizing stock hinges and lock latch, it can be flipped up to allow access to the storage compartment in the tail unit, a very handy touch. The

tail section saves a few pounds over the stock steel rear fender, especially if a smaller accessory type taillight is used in place of the bulky stocker. This particular tail section offers plenty of space to mount a license plate too. The entire tank, seat and tail section can be had for $235.

Fairings are a matter of taste, and every day there seems to be a new one on the market. Our unit comes from Dick’s Cycle West (one of the major Southern California cafe racer accessory suppliers), and is called the Racer 1 3/4. It was a bear to mount—mostly because of poor brackets—and once in place shook around excessively. Since the stock headlight fits right in place in the opening provided, the shaking creates a kind of light show if you ride at night. People in front of you wonder what the heck is going on behind them with that light bobbing around. But it provides a nice windbreak and seems to work well otherwise. Too bad it shakes. Inside our fairing we fitted a dash unit from Dick’s lA fairing. Though trimming was necessary, it added a nice touch.

If smaller fairings are your bag, another one to consider is the Vi unit made by Cycle Craft. It includes a dash, windshield and all the necessary brackets for an easy installation. The price is about $65.

We fitted front turn signals from a Yamaha Enduro that normally mount to the handlebars. Be sure to replace the 6-volt bulbs with 12-volt items for use on the 350. Your local Sears store bicycle department sells the rear view mirrors for $3.50 each. They work pretty well too.

Bars are another preference item. Some like ‘em low, some like ‘em high, but the lower they are the more money you’ll spend on chiropractic services. The clubman bars we used keep things to a happy medium...low wind resistance, good riding position with no need

for pain pills after a spin. J&R Manioke -turing builds these out of thin-1®rl, heat-treated chrome moly tubing. They’re strong, they’re light in weight and they’re comfortable. The price tag is $15.95.

Rear-set footpegs are in and work nicely in combination with a set of low bars. General Engineered Products made ours and they are designed to use the RD350’s rear footpegs. The brackets are heat-treated aluminum, featuring flatblack paint with polished fins.

A new brake pedal and linkage set-up is employed, replacing the heavy stock pedal and yoke assembly. The brackets fit the existing holes on the muffler bracket. By using the rear Yamaha footpegs, the front footpeg and bar assembly (5 lb.) can be eliminated. All that one must do in the way of installation is bend the .25-inch brake rod to fit the new brake arm on the rear-set,Ækn off the end and fit a cotter pin. A WKp included in the kit relocates the brakelight switch.

•Shift linkage is simply a bolt-on Oration, and total time to install rear-sets and all associated pieces is about 30 minutes. Very simple, even for the non-mechanically inclined.

WHEELS AND SUSPENSION

Forks used on the RD350 are very similar to the units fitted to larger Yamaha Enduros, with slightly different fork legs to accommodate the disc brake. Even though suspension units on a street machine don’t take the rough beating that units on a motocrosser do, a few roads around can make things miserable at speed. For this reason we installed a Number One Products “Trick Kit” fork kit to give us an edge. 180ccs of 50 wt. fork oil worked well for us, as did the stock fork springs. Fork legs were turned down in a lathe for appear-

«e and the finish is Kal-Guard’s Gun :e, with the fins polished.

We used a wide front fender for more protection from dirt and water. The unit is another product of Dick’s Cycle West and weighs just 1.25 lb., trimming nearly three pounds off the total of the stock model. Aluminum brackets have to be fabricated to mount the new fender.

Even though standard 350 brakes work well, we again took things a step further. We added a disc unit at the rear (carrier, caliper and disc are standard Yamaha items), then had both the front and rear discs drilled and chamfered to save about 21 pounds per wheel in unsprung weight. This is a step requiring the services of a good machine shop or an outfit like Racecrafters where we had ours done. If the price of $40 per disc seems high, consider the facts that the operation is very time-consuming and that the hardened steel discs require the use of ultra-high-carbon cutting tools.

Koni shocks are fitted at the rear, but, once more, we went a step beyond the norm. The Koni housings were replaced with Wheelsmith Engineering’s $40 aluminum housings that are being used on so many motocrossers these days. 1 lOcc of Bel Ray 300 shock oil in each is just the ticket. We weren’t after an oil cooling advantage with this change; it was simply for cosmetics. Wheelsmith charges $10 extra to install the Konis into their housings. S&W 75-lb. springs complete the shock picture at the rear.

Morris Industries’ aluminum wheels are probably the strongest anywhere, as can be attested to by the fact that many of the top factory road racers are using them. Elliot Morris is a perfectionist and it really shows in his finished product. The production rims are centrifugally cast in aluminum alloy and are 100 percent penetrant-inspected. They’re available in a natural finish, or black anodized with hi-lite polish. Specs are purely to aircraft standards. All kits, whether they be in the 16, 18 or

19-inch size, come with bearing hub adapters and spacers. The standard Yamaha front disc carrier bolted right to the front wheel.

The trick-looking aluminum sprocket is from Circle Industries and is a special cush drive unit. The cush drive greatly reduces wear in the drive train, especially the transmission. The sprockets come with several lightening holes, but we added more, chamfered the edges and painted the insides of the holes blue to accentuate the appearance. With three more teeth on the rear sprocket and the larger tire on the rear, we approximated the same overall gearing as stock. Drag racing or quicker acceleration would require a 14-tooth sprocket on the engine rather than the stock 1 5-toother.

The torque arm is a specially fabricated unit that you can duplicate in your garage or at the machine shop at your local adult education facility.

The biggest problem we faced on the entire machine was finding a master cylinder. The magnesium Lockspeed systems from England are probably the best, but nobody has any. Brad Stanley of Speed & Research said he could solve our problem by mounting a Girling sports car master cylinder similar to that he was using on his road racer. Sure enough, after a few brief tests, the system worked perfectly.

Brad machined the housing and the installation ended up being a snap. The reservoir was custom-made and mounted directly to the master cylinder. Brad may have started a big trend with the disc brake guys. The price of the master cylinder is about $30 and the reservoir is $18.50 from Speed & Research. They were also the ones who fabricated the stainless steel braided brake lines. Kits are available for most Yamahas for $19.95.

Tires are extremely critical on a machine of this type and we pondered several before we made our choice. Our

timing was just right to get our hands on a new set of Goodyear prototypes we had been waiting to try for some time. They will be available for sale by the time you read this. Fitted at the front is an MJ90 3:25-19 raised-white-letter job that retails for about $40. The rear is an MN90 4:00-18 that sells for about $50. Tread pattern was developed from racing and is the same compound as the famous Goodyear D/T rubber used on the National dirt track racing circuit. The tires on de Cafito are the same as the ones used on Yvon DuHamel’s winning production class Z1 Kawasaki.

The new Goodyears are “low profile” in design with a 90 percent aspect ratio, which represents the height of the tire versus the width of the rim. Most tires have a 100 percent aspect ratio so you can see what is meant by low profile. Though it’s too early for us to comment on tire wear, we can comment on road holding and overall tire feel. Looks as though the new Goodyears are going to be the hot set-up for the cafe crowd. They not only look superb, they work wonderfully. Goodyear has the answer with this one.

ENGINE

Our goal was to substantially increase the power over a usable powerband without hurting reliability or street worthiness. There is nothing worse than a machine that breaks down in rush hour traffic or that won’t start just because the owner wanted better performance. We wanted none of that stuff. Yamaha had already given us an excellent start with an engine that is a performance rocket. It’s a good example of how racing heritage improves the breed. Over the past five years, Yamaha 250 and 350 production racers have been the standard mount for amateur road racers the world over professionals too. The street equivalents share many similar

features. Perhaps this is one of the m^A impressive things about Yamaha a^i manufacturer; they are deeply involved with the racing aspects of motorcycling and are usually the first ones to innovate racing improvements into their standard production motorcycles.

As far as the 350s go, there are many similarities between the RD street bike and the TD series road racers. Absent on our machine is a wet clutch; gear ratios are spaced for street riding...but you’d be amazed at how close the engines are.

Our engine was prepared by Gene Schroeder and Jeff Cowan of Fairway Performance Products. Modifications are briefly described as follows: The heads were turned on a lathe and cc’ed, and the compression ratio was brought up to 8.0 to 1, corrected. We removed 0.072 in. from one head and 0.080 in. from the other. The angle of the squish band was recut to 17 degrees to allo^^A 0.050-in. deck clearance. We substitut^i a pair of Champion L57-R plugs for the standard ones.

^^The piston modifications were made I^Fincrease rpm and horsepower, but they definitely are not a longevity item. The intake timing was increased (Poor Richard defines as: “more gas per rev”), to supercharge the incoming fuel charge via cutting the piston skirt on the intake side of the piston at the top of the intake holes. The holes are extended straight down; however, the reinforcing ribs in the piston must remain.

The crank assembly modifications are for the Sunday racer in the production and cafe racer classes. A road racer crank assembly was substituted, not for increased ponies, but for reliability during those extended nine grand tach readings. This little swap over gets expensive. It involves two road racing rod kits, which include roller bearings (as opposed to ball bearings), to handle heavier loads, a slotted rod to increase

Äoil feed to the crank for more life er high rpm and finally those neato silver-plated titanium bearing cages that add that all important pizazz.

The crank was disassembled, the new parts substituted, reassembled and trued to within less than 0.0005 in...and that’s close! This tight tolerance greatly helps reduce vibration and horsepower loss at high rpm.

Our inner and outer clutch hubs were drilled out to save a few ounces and dazzle any onlookers who might observe our disassembled engine. The cylinder porting basically involves raising the exhaust port to 27mm from the stock 29.5mm, widening the exhaust to 42mm and matching the transfer ports. The key to the whole thing is in shaping the exhaust port correctly so that the ports don’t swallow the Dykes rings.

Being great believers in reducing friction, we contacted the Kal-Gard people and they convinced us that we should try coating the engine internals with Kal-Gard. They claim a 10 percent increase in horsepower and a substantial lowering of the transmission oil temperature. We figured that since it must run cooler and slipperier with Kal-Gard, we would put less oil of a thinner type in the trans. So far, so good.

To improve the breathing efficiency, we installed a K&N air filter. Don’t try to install any air filters directly onto the carburetors. The only way to go is to keep the still air box and replace the stock filter.

Many hours were spent on the dyno developing an exhaust system that would develop more horsepower over a broader powerband than the stock system and still be as quiet. We tested several of the leading expansion chambers on the market, and, interestingly enough, only one was better than stock Yamaha pipes. Obviously, Yamaha units are extremely well designed...making our job really tough.

Chuck Kayser, of J&R Expansion Chambers, worked hard on the project and came up with a pretty good answer. The first set worked well from 5 500 rpm on up, but they lost five hp right at 5000 rpm, creating a flat spot smack dab in the middle of the power curve. Chuck then modified the rear cone and picked up four of that lost five horsepower, and gained everywhere else in the process. We used a rear wheel dyno and obtained a steady progression of a four-hp increase over stock at 6000 rpm up to a 10-hp increase at 8000 rpm. The J&R pipe revved to 9000, or about 1000 rpm higher than stock.

This is basically a simple change, consisting of merely bolting on a set of pipes for an increase of about 23 percent in horsepower. The powerband also becomes higher and wider. Normal installation involves cutting off your RD350 head pipe about two inches and bolting the J&R units on. Everything fits as it should, but ground clearance seems to suffer a bit. de Cafito drags Eie ground too early at present, and ^A weren’t able to solve the problem before this issue went to press. The right pipe drags, as does the left when the sidestand is removed, so we’ve still got some work ahead of us. After all, handling is a great big part of cafe racing, and making sparks on the pavement with your pipes just doesn’t get it...especially when the pipes set you back $80 or $90, depending on whether they’re chrome or flat black.

COSTS

To give you an idea of what some of these modifications cost, we’ll give you Fairway’s charges for their services. Other dealers or shops will probably vary. That’s why it’s always a good idea to shop around and determine who can do the best job for you. Talking to customers in and around the sho^^^ another way to insure yourself that place is reputable. Here’s how Fairway works it.

If you want the whole shootin' match they need your crank assembly, both heads, both barrels and pistons, and will ship you the high performance package for $200. Prices separately are:

1. Racing crank assembly service $36, plus two rod kits at $24 each and two roller bearings at $ 1 6 each. Total crank service is $1 16.

2. [[lie best pertormance buy in the engine itself is the $90 special that includes porting both cylinders and modifying the heads and pistons. This is t recommended budgeteer plan to d e the speed freaks.

3. YOU can get the J&R pipes for $79.95 in black or for $10 more get

chrome. Chrome is for sissy cafe racers, however; flat black is in.

4. The drilled inner and outer clutch hub costs $12.50 exchange.

Finishing off de Cafito is Porsche acrylic lacquer from their 1974 color list. We used Marathon blue, a good solid color with pin-striped highlighting. Clear bullet-proof epoxy was added to help protect the finish from fuel damage and possible chipping. Ronnie Lyster, a well known pin-striper in Southern Cali fornia, put his talents to good use on the RD Project bike.

Here are some hints to ease your mind financially with the project. Remember that many of the items can be removed if you sell your bike and can be sold for a reasonable percentage of their original cost. Or, you can transfer them to your next machine, perhaps with only minor modifications. Many people won't be willing to pay what you feel the accessories are worth when they are on a machine for sale, so put as much of it back in original condition as possible, and then sell your bike.

LIST OF SUPPLIERS

1. Wheelsmith Engineering 3635 W. McFadden Santa Ana, CA 92704 (714) 839-0150

2. J&R Expansion Chambers 1967 Glassell St. Orange, CA 92667 (714) 998-6410

3. Racecrafters International 7916 Sunset Blvd. Hollywood, CA 90046 (213) 876-3600 (catalog $1.00)

4. Fairway Racing Products 1350 F. Yorba Linda Blvd. Placentia, CA 92670 (714) 524-1205

5. Kal-Gard 7 118 Gerald Ave. Van Nuys, CA 91406 (213) 997-1673

6. Dick's Cycle West 304 Agostino San Gabriel, CA (213) 287-9656 91776 (catalog $2.00)

7. Morris Industries 3853 S. Main St. Santa Ana, CA 92707 (714) 540-5206

8. General Engineered Products 17332 Irvine Blvd., Unit N Tustin, CA 92680 (714) 990-0775 (catalog $1.00)

9. K&N Engineering P.O. Box 1329 Riverside, CA 92502 (714) 682-8813

10. Circle Industries 17901 E. Arenth City of Industry, CA 91746 (213) 965-1622 (catalog $1.00)

11. Custom Paint Work 581 S. Walnut La Habra, CA 90631 (213) 694-4164

12. Number One Products 1 1509 Bexley Drive Whittier, CA 90606

13. Speed & Research 501 W. Maple, Unit L Orange, CA 92668 (714) 633-9323

14. Cycle Craft 1572 Soquel Drive Santa Cruz, CA 95060 (408) 476-4566

(Continued on page 90)

Continued from page 41

On the other hand, if you need immediate financial assistance to buy an accessory, there are many parts readily saleable on your stock RD. For instance, any RD250 owner would be wise to buy your front wheel to convert to a disc brake. There are other similar examples.

It takes quite a while to build a machine such as this. Be patient and do a good job. Our machine took about seven months, but much of that was spent waiting for accessories to be designed and marketed.

A motorcycle is a compromise—none is perfect in all realms. Traits are juggled and traded off to obtain those desirable factors.

There is a great paradox in the motorcycle field. In road racing the Japanese easily dominate almost all major racing events (with the possible exception of MV Augusta in Europe). The Japanese have the most street-like street bikes and the most race-worthy race bikes, but they offer practically nothing in-between.

A few machines like the RD350 hint at sport, but nothing from Japan really is comparable to the European machines like the Ducati Desmo Sport and Moto Guzzi Sport. The European road racing motorcycles rarely place high in the standings of road race events, yet their sport offerings are about the only cafe racers on the market. We attempted to bridge the gap between the pure street bike and the pure road racer.

Cafe racers we’ve observed come in two general categories. The first group is modified for cosmetic appeal. The stock tank, seat, fenders, handlebars and foot controls are replaced with the latest high-fashion equipment. The second group normally includes most of the above modifications, but the machine is further refined for a higher level of handling and performance. These modifications consist of high-performance tires, improved shocks, lighter components—including alloy wheels—tanks, fairings, beefed-up swinging arms, highperformance exhaust systems, disc brakes, etc.

Our project attempted to incorporate both of the above. And, we included an explanation of the parts involved so that you could either duplicate this machine or parts of it, depending on whether you prefer performance or appearance.

Cafe racers are really starting to come into their own and, hopefully soon, we’ll see an exciting new era in motorcycling, thanks to machines such as de Cafito.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontMotorcycles, Rehabilitation And A Funky Jamboree

November 1974 -

Letters

LettersLetters

November 1974 -

Departments

DepartmentsFeed Back

November 1974 -

Departments

DepartmentsRound·up

November 1974 By Joe Parkhurst -

Features

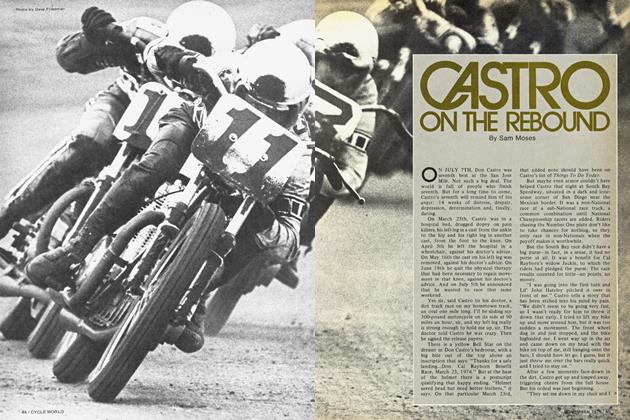

FeaturesCastro On the Rebound

November 1974 By Sam Moses -

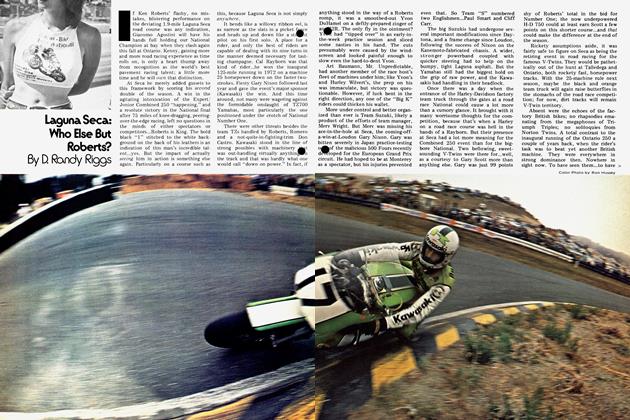

Competition

CompetitionLaguna Seca: Who Else But Roberts?

November 1974 By D. Randy Riggs