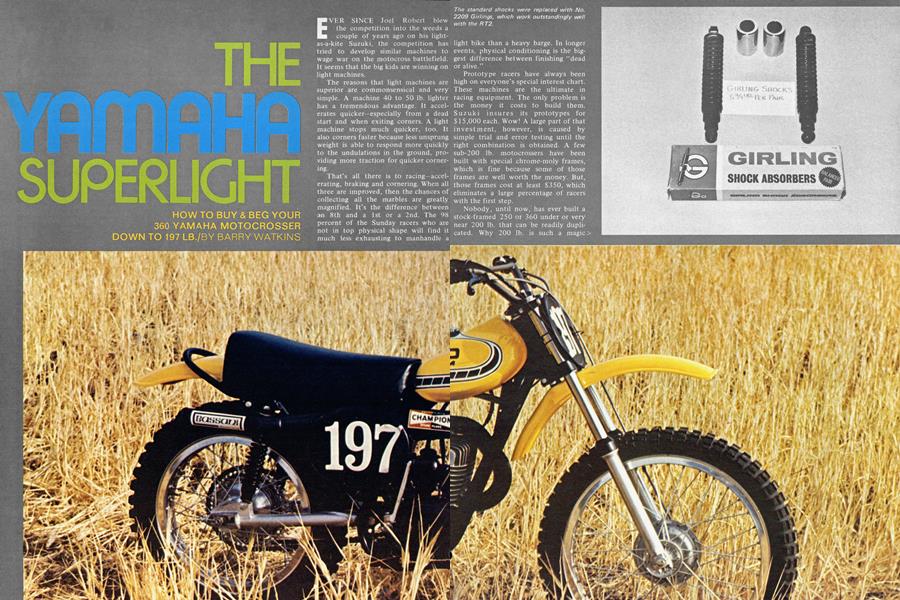

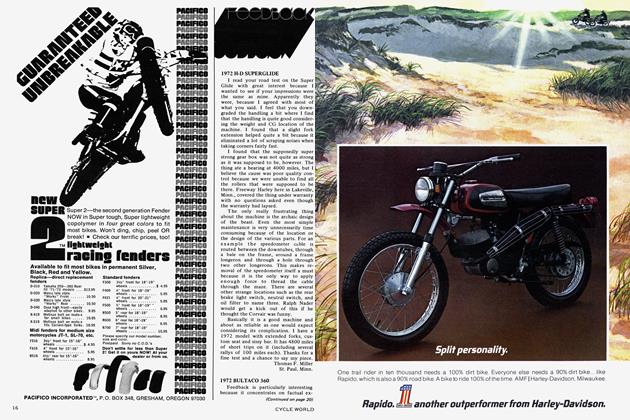

THE YAMAHA SUPERLIGHT

HOW TO BUY & BEG YOUR 360 YAMAHA MOTOCROSSER DOWN TO 197 LB.

BARRY WATKINS

EVER SINCE Joel Robert blew the competition into the weeds a couple of years ago on his light-as-a-kite Suzuki, the competition has tried to develop similar machines to wage war on the motocross battlefield. It seems that the big kids are winning on light machines.

The reasons that light machines are superior are commonsensical and very simple. A machine 40 to 50 lb. lighter has a tremendous advantage. It accelerates quicker—especially from a dead start and when exiting corners. A light machine stops much quicker, too. It also corners faster because less unsprung weight is able to respond more quickly to the undulations in the ground, providing more traction for quicker cornering.

That’s all there is to racing—accelerating, braking and cornering. When all three are improved, then the chances of collecting all the marbles are greatly magnified. It’s the difference between an 8th and a 1st or a 2nd. The 98 percent of the Sunday racers who are not in top physical shape will find it much less exhausting to manhandle a light bike than a heavy barge. In longer events, physical conditioning is the biggest difference between finishing “dead or alive.”

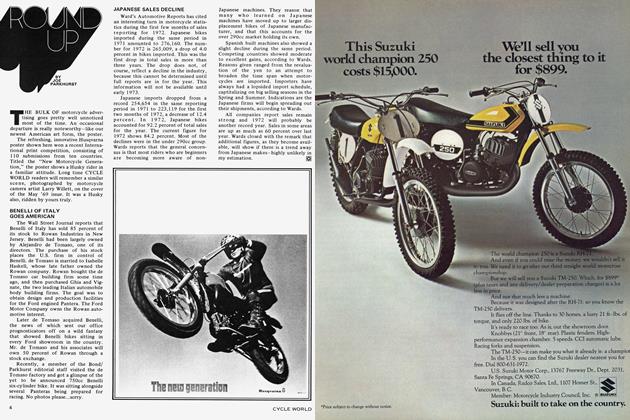

Prototype racers have always been high on everyone’s special interest chart. These machines are the ultimate in racing equipment. The only problem is the money it costs to build them. Suzuki insures its prototypes for $15,000 each. Wow! A large part of that investment, however, is caused by simple trial and error testing until the right combination is obtained. A few sub-200 lb. motocrossers have been built with special chrome-moly frames, which is fine because some of those frames are well worth the money. But, those frames cost at least $350, which eliminates a large percentage of racers with the first step.

Nobody, until now, has ever built a stock-framed 250 or 360 under or very near 200 lb. that can be readily duplicated. Why 200 lb. is such a magic weight I don’t know, but it is. Ten years ago, 300 lb. was a featherweight, so progress has been made.

The home offices of Yamaha and Suzuki were contacted to see if they would allow us to copy some of the tricks on the prototype racers and incorporate them into a project bike. Suzuki gave a flat "‘no” for an answer. Yamaha’s answer was a very positive “yes>” and it would supply other technical information, if necessary.

Yamaha has incorporated its racing knowledge into the 1972 MXers and has made several radical improvements, such as an excellent handling frame, while Suzuki still sells a street handling frame in its MX models.

The new Yamahas were possibly the best buy on the market this year with all the new changes it has incorporated with the last two years’ racing experience at hand. Readers can perform a major share of the modifications, or a facsimile thereof, to their own brand. A great amount of time was spent researching, weighing and testing different parts from a multitude of sources. We even located a top notch machinist that can supply some of those trick parts on a mass production basis at very reasonable prices.

The finished product is well worth the time and money. There is no substitute for weight reduction.

There is the possibility of a weight limit for international racing. It is about 207 lb. dry for a 250 and about 218 lb. dry for a 360. The point is, you may not need to build a sub-200 lb. machine for competition in international events. This article should be very important anyway, because it gives important clues to where to put the lightest parts and where the money would be best spent. Use the information to the best advantage and spend a lot of time planning it before spending any money.

This project bike took over six months to build, but that was because everything had to be designed, built and tested until it was all just right. With that in mind, let’s see how to build the world’s first do-it-yourself, stockframed, sub-200 lb. 360.

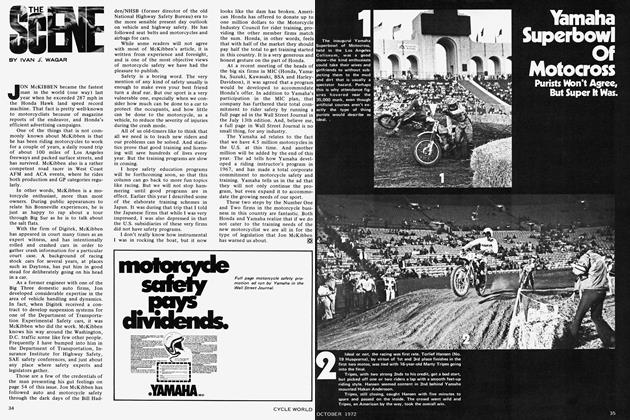

ALUMINUM SWINGING ARM

Yamaha must have melted down the whole rear quarter section of one of those World War II Japanese battleships and put it into each and every swinging arm it makes. In defense of the heavy swinging arm, however, it’s probably the standard in the industry for strength and rigidity. How many broken Yamaha swinging arms have you seen?

The swinging arm and all attachments including the swinging arm bolt, chain adjusters, bushings, etc., tips the scales at 9-1/2 lb. Believe it or not, there is a brand new aluminum swinging arm on the market manufactured by Boyd and Stellings in Santa Ana, Calif., that can save 4-1/2 whopping lb. of unsprung weight. It’s been thoroughly tested and is just as rigid as the Yamaha set-up.

It’s easily one of the most important items to consider in rebuilding a machine. Quite a lot of thought went into the design of the unit to make it strong, rigid and light. The front portion of the swinging arm is a well designed casting and the arms are special aluminum tubes of 0.120-in. wall thickness. The unit is heli-arced together and heat treated in a jig to keep it from warping. It features over 1-in. more of rear wheel axle adjustment than the standard Yamaha component, too.

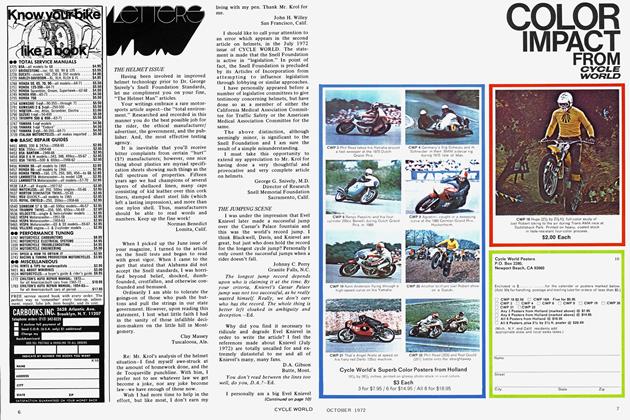

GIRLING SHOCK ABSORBERS

The original Yamaha YZ shocks featured aluminum main bodies and a pair of these featherweight shocks with springs weighs only 4-1/2 lb.-3 lb. lighter than the standard enduro shocks. They are not available to the general public and Yamaha can’t get any more, either. Forget the aluminum housings because there are expensive problems to overcome, such as flexing and wearing out prematurely on the inside.

After the Yamaha racing team wore out those prototype shocks there were no more available. That led to a number of experiments with production shocks and when all was said and done, Girling’s model No. 2209 was by far the best tested. The No. 2209 is the same one found on the late model Husky motocrossers. These shocks, at 5-3/4 lb., weigh 1-1/4 lb. per pair less than standard Yamaha units. That’s a pretty fair swap-get the best shocks on the market and save some unsprung weight in the exchange. The Husky Girling shocks are 1-in. shorter than the standard shocks, which helps the high speed handling on the RT2. The shorter shocks raise the swinging arm to a horizontal position, which eliminates the moment of force in the arm below the horizontal position, thereby greatly reducing rear wheel hop.

The aforementioned Girling shocks come with 75-lb. springs, which seem to be perfect for the new Yamahas. Torsten Hallman Racing distributes a unique spring which allows full shock travel, due to its light spring weight. These springs are easily recognizable due to their solid gold color.

If you want to nit-pick, the chromed mud covers on the Girlings can be tossed out and the savings will be about half a pound. Girling shocks are available at dealers through Torsten Hallman Racing in La Mesa, Calif.

Remember, spring rate is a function of rider, unsprung and sprung weight, so buy the springs after the bike is down to its target weight.

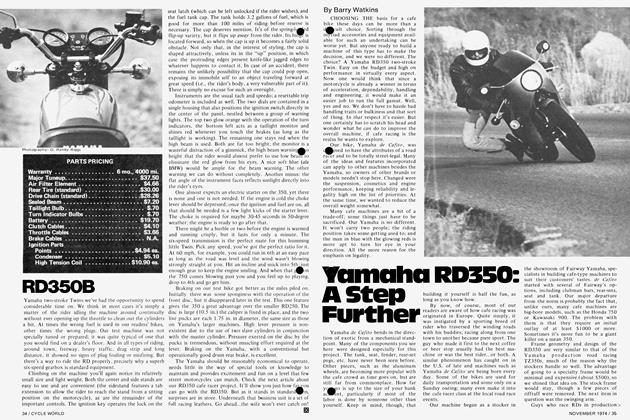

REAR WHEEL ASSEMBLY

Probably no other portion of the motorcycle is as important as the unsprung weight on the rear end. The front wheel is aviated a much higher percentage of the time to dodge bumps and the rear wheel is the one that propels the motorcycle. It is a wellknown fact that the more time the wheel is on the ground, the faster the machine will accelerate and decelerate.

A light rear end is able to respond much more quickly to the ups and downs of a rough motocross course and put the wheel back on the ground quicker.

The rear wheel assembly shown is possibly the lightest combination ever put together for this type of machine. Total rear wheel weight of our project bike, including the complete hub, spokes, sprocket, rim, bearings, spacers, tire, tube and rim locks, weighs just a shade over 25 lb.-that’s over 3 lb. lighter than the Yamaha and Suzuki prototypes. The combination can be put together for a fraction of the cost of those prototype magnesium castings, still saving 3 lb.

There are a number of excellent rear hubs on the market and the ones with the best brakes are the following: Greeves, Maico, Husky, and CZ. The weights of those complete hubs vary considerably, from 7 lb. for the Greeves to about 10 lb. for the CZ. The Husky and Maico hub are both close to 8 lb The brakes and strength of the hub should be the most important factors in selecting any hub and it so happens that the Greeves Griffon is one of the strongest, fastest stopping and lightest hubs around. At 7 lb. for the complete hub, the backing plate accounts for over 2-1/2 lb. of that weight. Raines Engineering came up with a one-of-a-kind backing plate that saved over 1 lb. of unsprung weight. The brake shoes were drilled and lightened and the steel internal bearing spacer was replaced with an aluminum one.

The Greeves hub is conical and is one of the best looking units on the market. They are available through Nicholson Motors in North Hollywood, Calif. Prices are about the same as other outstanding hubs on the market.

We went to Buchanan’s Frame Shop in Mionterey Park, Calif., and Jim Buchanan spent quite a bit of time weighing spokes and nipples before we had the right combination for weight and strength. Spokes are categorized by gauge, the lower the number the larger the diameter. A set of 40 spokes, 8 gauge, weighs 2-1/16 lb., while a set of 9-gauge spokes weighs 9 oz. less. For motocrossing, 9-gauge spokes may be sufficient, but for rompin’ in the desert 8 gauge is better. Buchanan’s also makes, on a limited basis, nipples made com 70-71 aluminum. A set of 40 nipples weighs only 3 oz. If Buchanan’s spokes the wheel, the spokes may never have to be tightened again.

If starting from scratch and a rim is needed, Akront is a good way to go for motocross. At 4-1/4 lb., they are light but strong. Desert racers normally prefer steel rims because of numerous encounters with rocks. If a steel rim is used, the weight penalty is at least 2 lb., but steel rims do have their advantages, especially in the rocks.

Tube weights vary by as much as 1 lb. and there are several good brands. For motocross, get the lightest possible good tube, since flats are seldom a problem.

Tires have to be considered from .many points. Traction, durability and cost are the most important considerations. Dunlop’s K-88 4.60-18 is the lightest knobby tire on the market at 10-1/2 lb. They really grab the ground but don’t seem to wear as well as some of the other tires on the market. Full Bore’s 4.20-18 at 11-1/2 lb. is a super traction tire, lasts a long time and is very competitively priced. It is distributed by Yankee Motor Co. (the Ossa people) in Schenectady, New York. Goodyear has just introduced a new super tire called the Eagle MX. It weighs 12 lb., is 4-ply nylon and lasts a long time. The Eagle MX is available in both 4.00-18 and 4.50-18 size. The Goodyear Eagle is nationally distributed by Buco.

Light tire weight is important not only for the effects of unsprung weight but also because the inertia of a light tire is much easier to overcome for faster acceleration. Two, 3 or 4 lb. at an average distance of 20 in. from the axle requires more horsepower to overcome its moment of force than a light tire.

Circle Industries, the world’s largest manufacturer of sprockets, in South El Monte, Calif., makes about any type of sprocket. I spent about an hour drilling one out and saved about 10 oz. for a final sprocket weight of 12 oz.

Circle Industries also makes countershaft sprockets from 12 to 17 teeth for Yamahas and all kinds of sprockets for other engines and hubs. Many of their sprockets already have lightening holes and are called “Weight-Watcher” sprockets. According to the above, the rear wheel assembly will be about nine (yes, nine) whopping pounds lighter than the standard RT2 setup. If you incorporate Boyd and Stellings swinging arm and Girling shocks, the total weight savings is over 14 lb. And that really makes a tremendous difference in handling. If you’re on a limited budget, the elimination of these 14 lb. should be priority items. Don’t overlook unloading existing parts at the swap meet and applying that amount toward the purchase of new parts.

REED VALVE ENGINE

Yamaha has made a radical departure with its reed valve engine this year. Both the 250 and 360 have substantially more power, more torque, and accelerate faster than last year’s corresponding models.

The 360 engine in stock form, complete with carburetor, weighs about 74 lb. The 250 is about 5 lb. less, basically due to the lighter cylinder. There are confirmed rumors that Yamaha will be making some hard-chrome lined cylinders for the DT2 and RT2 motocrossers. We hope they do because they are not only 4-1/2 lb. lighter but increase performance substantially. The piston can be run at much closer tolerances to the cylinder wall. When the engine heats up, the piston and cylinder expand at the same rate, hence no loss of compression and more horsepower. The all-aluminum cylinder also dissipates heat more readily for a cooler running engine.

One trick you can do to the barrel is to drill lightening holes in it. The secret is to keep the holes small but numerous so that the surface cooling area is not decreased. As much as 2 lb. can be lost. Not bad—6-1/2 lb. lost and only one item changed.

The next item is to remove the oil pump and oil can. The oil pump weighs almost a pound and the oil can when full weighs over 2 lb. That’s a quick and dirty trick to eliminate 3 lb. Don’t forget to plug the oil line hole in the cylinder to prevent an air leak. A good oil must be used if the pump is eliminated, such as Torco’s new T2R. Mixed at 40:1, we are very satisfied with its lubricating properties.

Advanced Cycle Engineering in Inglewood, Calif., is making straight cut gears for Yamahas. It’s the only way to go for a racing machine. The bottom end will last much longer because they take the side load off the crank bearings. They also help the transmission shift better.

Raines Engineering copied a YZ clutch assembly from a billet of aluminum that looks like a piece of Swiss cheese. The heavy springs and metal plate were eliminated and 1-1/4 lb. were saved. We eliminated the cush-drive which has its advantages, but the weight saved allows the engine to rev quicker.

The RT2 comes stock with an excellent CDI unit. The DT2 is equipped with a lightweight magneto. Both units eliminate a substantial amount of rotating inertia compared to previous models which help acceleration almost as much as any other engine modification. Where it really makes a difference is drag racing to the first turn in a moto or exiting a turn. The engine revs quicker and explodes out of corners.

However, the powerband on the RT2 can be smoothed out some and made a little easier to ride by installing the standard heavy mag such as on the enduro models. The choice of mag should be determined by riding preferences.

The transmission gears were beveled to decrease surface area and friction. Then the gears and most other moving parts were sent to Microplate Co. in Inglewood, Calif., to microplate the gears. Transmission life is greatly increased and friction is reduced substantially. Microplate claims at least a 25 percent loss in friction. Gear life is almost infinite once microplated because the film is so hard. Similar treatment was applied to the cylinder barrel.

Mid-range and top end performance can be increased through the addition of Mikuni’s 38mm carburetor. The reed valve engine is ideal in that an extremely large carburetor can be used with no fear of “drowning” the engine because it only inhales what’s used. It is much more efficient than piston port engines. The Mikuni works equally well on the reed 250s or 360s.

The standard expansion chamber is a well designed unit for high rpm, but needs some changes to smooth out the low to mid-range transition. It is not a

lack of low end, but a sudden abundance of ponies from about four grand up. The complete expansion chamber and silencer weighs about 8 lb.

Bassani Mfg. spent quite a bit of time and had a lot of free rides helping develop an ideal pipe. The final product is quite an improvement—more power throughout the entire powerband. More importantly, however, the low to midrange powerband was smoothed out considerably and it doesn’t have that sudden surge of power as before. With the Bassani pipe and the 38mm Mikuni, the RT2 is quite competitive.

The Bassani pipe is 4 lb. lighter and is a super quiet pipe. If everyone installs a quiet pipe there may be somewhere to ride next year, so put one on.

The total weight savings in the engine and related components is about 15 lb. It is not as important as unsprung weight, but it’s all the less weight to lug around. A pound here and a pound there.

FRAME: IT HANDLES AS IS

Yamaha has really done its frame homework with its 1972 models. They’re still about 10 lb. heavier than the super custom chrome-moly frames, but they can be made to handle quite well, with the simple addition of a pair of 1-in. shorter shocks on the rear to level the swinging arm. This year’s frame weighs 28 lb. and most of the Mickey Mouse brackets have been eliminated so the weight is about as light as possible. It’s the only Oriental frame that doesn’t require alteration to make it handle.

Part of the beauty of this whole project is that an expenditure of $300 to $500 for a frame is not required to build a sub-200 lb. motocrosser. If you have an earlier model Yamaha and want to go the new frame route, three manufacturers stand above all others. Doug Schwerma of Hayward, Calif., and Boyd and Stellings in Santa Ana, Calif., make the best chrome-moly frames and Jones Motocross Products sells a chrome-moly replica of its factory racing team Yamaha YZ frames.

FRONT END SWAPS

A light front end is very important but not quite as important as a light rear end. A light front end can be easily lifted over troublesome obstacles and will follow the undulations much easier than a correspondingly heavy front end.

The conical hub on the new Yammies is strong, light, inexpensive and has a super brake. It also happens to be very competitively priced. The entire unit weighs about 5-1/2 lb. and can be lightened by 4 or 5 oz. by drilling the backing plate and brake shoes.

For any other type of lightweight racer, the RT2 hub is good, but over a pound can be saved by using a Husky 250 front hub. Husky parts are just like their motorcycles, dependable and high

quality. The brakes can be improved considerably by having the shoes arced to the brake drum. Cost of the complete Husky hub, with spindle, is less than $60.

Half the weight of the front axle can be saved through two sources. Harry

Hindall in Venice, Calif., makes excellent tubular heat-treated chrome-moly axles for $6 and that’s a great buy. Or, you can go first cabin with Torsten Hallman’s titanium axles and spacers.

Akront rims are the only way to go. They have several varieties of 21-in. rims and some are as light as 3-1/4 lb. The heavy-duty Akronts are about 5 lb.

The light front tire market is owned by Dunlop with its 2.75-21 in. doughnut at only 7-1/2 lb. It’s the only tire under 8 lb. Full Bore has a 3.15-21 in. tire at about 8-1/2 lb. that is a super tire because of the exceptional traction it allows, especially in high speed cornering.

(Continued on page 99)

WHERE TO GO

If you want to duplicate the project in whole or in part, the following list of suppliers should be very helpful.

1. Titanium axles. Girting shocks and springs, titanium handlebars, aluminum tank: Torsten Hallman Racing, 5345 Timken St., La Mesa, Calif., (714) 460-6234.

2. YZ tank, turtle tank, engine blueprinting and porting, YZ clutch side cover: Jones Motocross Products, 20868 Currier Rd., Walnut, CA 91789, (714) 595-9100.

3. Aluminum swinging arm: Boyd and Stellings, 2111 So. Grand Ave., Santa Ana, CA 92705, (714) 557-3914.

4. Machine work on fork legs, brake backing plate and YZ replica clutch hub: Raines Engineering, 1515 N. Kraemer Boulevard, Unit G, Anaheim, CA 92806, (714) 630-0669.

5. Heat treated chrome-moly axles: Harry Hindall, 938 Indiana Ave., Venice, CA 90291, (213) 392-7426.

6. Sprockets: Circle Industries, 2536 Seamen, South El Monte, Calif., (213) 686-1669.

7. Wheel spoking and balancing: Buchanan's Frame Shop, 629 E. Garvey, Monterey Park, Calif., (213) 280-4003.

8. Greeves hub: Nicholson Motors, 11573 Van Owen, North Hollywood, Calif., (213) 764-8674.

9. Straight cut gears: Advance Cycle Engineering, 929 Hyde Park, Inglewood, Calif., (213) 677-5677.

10. Microplating of transmission gears and cylinder: Microplate Company, 1013 W. Hillcrest, Inglewood, CA 90301, (213) 776-5686.

11. Polycarbonate clutch and brake levers: Unifilter, Inc., 1350 W. Collins Avenue, Orange, CA 92666, (714) 639-0754.

12. Paint job: Paint by Molly, 589 S. Walnut, La Habra, CA 90631, (714) 871-4590.

13. Expansion chamber: Bassani Mfg., 1117 Fountain Way, Anaheim, Calif., (714) 630-1821.

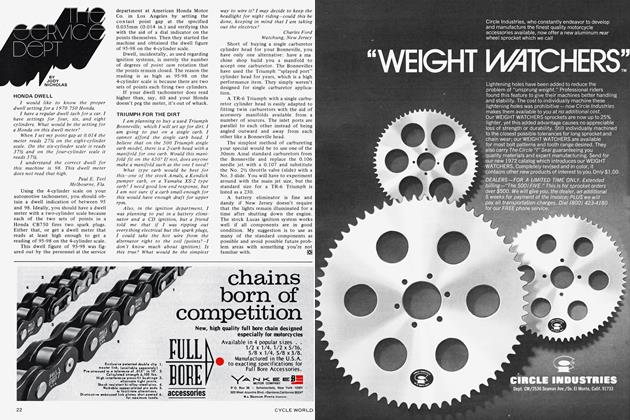

COMPONENT WEIGHT in pounds

Continued from page 71

A pound can also be saved in each one of the aluminum slider legs on the forks. Raines Engineerings turned them down on a lathe and a mill and they are one of the few outfits set up to produce them on a mass production basis. They will machine them for only $30. The legs are still plenty strong, and two more pounds of unsprung weight can be saved. Besides that, they really look prototype. Raines Engineerings can also turn most other brands of fork slider legs down.

The 1972 Yamaha fork crowns are possibly the best of any motorcycle this year. Well designed aluminum castings are light and strong. They are so light that there would be no weight savings if they were fabricated from titanium. The fork crown bolts were replaced with aircraft quality aluminum nuts and bolts. The big trick was to replace the heavy fork crown stem with a titanium duplicate. Total weight savings in the fork crowns was about a pound.

Atop those fork crowns rests one of Torsten Hallman’s Husky titanium handlebars. Even though only three-fourths of a pound lighter than the standard bars, that does not give a true picture, as Yamaha makes an exceptionally light handlebar. Titanium bars can save as much as 2 lb. depending on the brand of machine.

Titanium parts are naturally more expensive than corresponding steel or aluminum parts, but weight is really important at the~ top of a scooter. It’s weight that has to be thrown around, and in a long race, anything to keep from being prematurely exhausted greatly improves a racer’s chances of winning. In addition, a machine that is light atop is more comfortable to lean over in the turns.

Another brand-new product is Unifilter’s polycarbonate clutch and brake levers. Two of these weigh only 1/2 lb., which is half the weight of aluminum levers. The best part is the knobs don’t break off and they are almost indestructible. These are truly a breakthrough.

To sum up the front end, a total of about 6 lb. can be saved. With the Husky hub the total front wheel assembly weighs in at just under 18 lb., which is 2-1/2 lb. less than the Yamaha standard equipment. Don’t trade the ’71 or ’72 Yamaha forks for anything. They’re as good as the best. Just turn the slider legs down and save 2 lb.

(Continued on page 102)

Continued from page 99

MISCELLANEOUS ITEMS

To push the 200 lb. barrier requires a lot of attention to small details. You won’t make the weigh-in unless you do spend a little time on the small stuff.

For instance, the skid plate is l lb. that can be eliminated for motocross. It’s not a critical l lb., but by taking off a pound here, another pound there, before long lO lb. have been removed and that will make a difference.

The kick stand is another l-l/2 lb. A lot of people prefer to have the convenience of a kick stand, and it is a sacrifice to be without one. But if everyone has a kick stand, who is going to buy all of Webco’s bike stands?

The new Yamaha seat, at 4-1/4 lb., is hard to beat for comfort and durability, plus it’s plenty long for climbing all over the bike and still having something there. The standard equipment is best. Yamaha has a well-designed fiberglass base that is a partial fender and air box splash guard. It’s quite well constructed.

Believe it or not, the number plates, while functional, are about 2 lb. heavier than necessary. I replaced mine with some flexible plastic number plates. A complete set of three is only about $4. When the standard number plates break, replace them with some of these.

It seems as if 5-10 lb. could be saved by replacing all the itty-bitty nuts and bolts with aluminum or titanium ones, but it can’t. Excluding the engine mounting bolts and the axles, all those gillions of nuts, bolts and screws only weigh about 2 lb. Titanium weighs approximately one-half the weight of mild steel and to replace all the nuts and bolts with metric titanium nuts and bolts would probably cost more than the motorcycle—a very expensive l lb. savings. Aluminum weighs about onefourth the weight of mild steel and has considerably less strength. For safety’s sake, do not use any aluminum bolts in highly stressed areas such as fork crown stems, engine mounting bolts (there’s a lot of vibration), footpeg brackets, axles, etc.

Fuel tanks also warrant close attention. The choice here will make the biggest difference in styling of any item on the motorcycle. There are basically two types—aluminum and fiberglass. The choice of tanks should in part be determined by how low the fuel is carried. The lower the better because the center of gravity is lowered. The difference is easily noticed when cornering. A low slung tank doesn’t have that top heavy feeling.

The lightest tank on the market is the Jones Motocross Products’ fiberglass replica of the YZ tank at 2-1/4 lb. That’s about a pound lighter than anything else on the market. It basically is a motocross tank that’s good for about a 30-min. moto—31 min. and it’s out of gas. I consider it the best looking tank on the market. Jones also manufactures what could be called a “turtle tank” for desert fans that holds over 4 gal. of gas.

Torsten Hallman distributes a fine looking aluminum tank which is imported from England and weighs only 3-1/2 lb. Excellent quality. The tank fits Huskys and the like better than Yamahas.

When the chain wears out replace it with a Diamond chain. It’s the best chain made and is available from dealers through Buco.

Although a paint job doesn’t save any weight, it sure can make an owner proud of his machine. Mine was designed and painted by the most famous painter in the industry —Molly, of La Habra, Calif. He is currently designing apparel and motorcycle paint combinations for Yamaha and something similar to the project bike’s paint may be seen on a later production machine from Yamaha.

Starting with a 237-lb. missile and removing 39-1/2 lb. makes this the world’s first stock-frame sub-197-lb. big-bore motocrosser (dry) that can be readily duplicated—and you can build it. Wet, with fuel in the tank, it weighs about 203 to 205 lb.

It’s about as close to the famous Yamaha YZ racers that the Jones family races as can be expected from a nonfactory replica. This YZ replica is a tremendous improvement over the stock RT2, which is already an excellent motocross entry. It handles better, accelerates quicker, stops faster, and corners more comfortably than the stock machine. From the whole project, take what is important to you and your machine and have at it. You’ll have a lot of fun and be thoroughly satisfied in the process. [Ô]