HANDLING STRESS BY MOVING IT

TDC

Indirect thinking can be powerful.

KEVIN CAMERON

Do you enjoy watching how humans analyze and solve difficult problems? If so, I recommend reading Honda R&D Tech Review 2009—F1 Special— The Third Era Activities. In that document, one item which stands out in my mind deals with preventing crankshaft cracking at the fillets joining the crankpins to the webs.

Unfamiliar with all this terminology? The engine’s crankshaft spins in two or more supporting main-bearing journals. Between each pair of journals is a crankpin, offset from the main-journal centerline by one-half of the engine’s stroke (stroke being the total distance each piston travels back and forth in its cylinder). The webs structurally join the main bearing journals to the adjacent crankpins.

Experience shows what happens when high stress is transmitted through a part having sharp edges or notches. The 1970 Kawasaki HI R 500 production roadracer I worked with broke cylinder studs, which were pieces of 8mm rod threaded on both ends. The studs always broke at the root of the first thread, where the relatively low stress in the stud’s full-diameter 8mm shank became a much higher stress in the threaded portion, whose cross-sectional area was only 60 percent of the shank’s.

I was able to stop those studs from breaking by using a round-nosed tool on my lathe to eliminate the sudden area reduction, reducing the shank’s diameter to slightly less than the root diameter of the threaded portion. Two weeks later Kawasaki mailed us warranty replacement studs. They looked just like those I’d reworked on the lathe.

For crankpins, the equivalent is to provide a smooth radius when joining the pin to the crank web. This radius, the crankpin fillet, changes the form of what might otherwise be a sudden, sharp 90-degree corner.

What happens without such a radius? Steve Whitelock, former mechanic to the late Yvon Duhamel, once worked in a Ferrari shop. He regales us with an instructive tale: When a reassembled engine was put back in the car and road-tested, its crank broke. The problem? The crank had been reground, and the grinder had failed to provide the original smooth crankpin fillets. Without such fillets, stress was severely concentrated at the sharp corner, producing a crack and failure.

Because crankshaft fillets are such sensitive areas, they are normally finished by putting their material into compression, usually by fillet rolling with a very hard radius-edged wheel, by shot peening, or by nitrogen hardening. Placing the surface in compression is effective against cracking; tension is its usual driving force, and if the surface is initially in compression, it must be deflected further before any tension can be produced by applied stress. Good insurance.

Even with such measures, the fillets of newly designed engines may still crack during product testing. If all else fails, the usual response is to make the fillet even more gentle by increasing its radius. The designer doesn’t like this: making room for the larger fillets means narrowing the bearing inserts to suit. This compromise has been quite common in sports and racing designs.

“Why not move some of that stress away from the crankpin altogether?”

In the case Honda describes in the aforementioned paper, the crankshaft was from a Honda V-10 FI engine running to over 1 9,000 rpm. Beef up the parts? Not possible; adding mass would just increase the crankshaft’s torsional vibration problems. Bigger crankpin? Sorry, FI engines must be mounted as close to the pavement as possible: a bigger crankpin requires a connecting-rod big end with a larger diameter, and that would describe a bigger circle as it whirled, forcing the engine to be mounted higher.

Some unnamed person approached this problem in a completely different direction. Instead of trying to find a new way to handle excessive stress in the crankpin fillets, why not move some of that stress away from the crankpin altogether, to a part of the crank better able to survive it?

Salvation. Using a radiused cutting wheel, a smooth groove was carved into the face of the crank web adjacent to the problem fillet. By thus “inviting” some of the flexure to occur elsewhere, in the deliberately weakened web, the problem fillet could now function crackfree for the desired racing mileage.

Indirect thinking.

View Full Issue

View Full Issue

More From This Issue

-

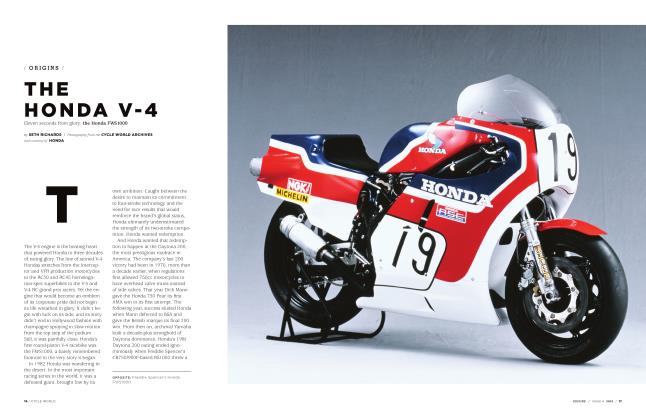

ORIGINS

ORIGINSTHE HONDA V-4

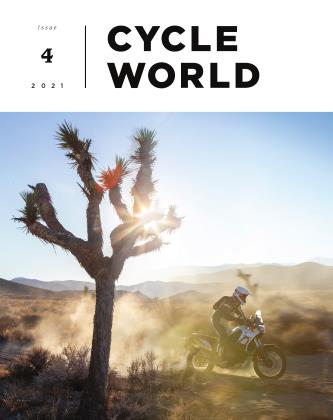

Issue 4 2021 -

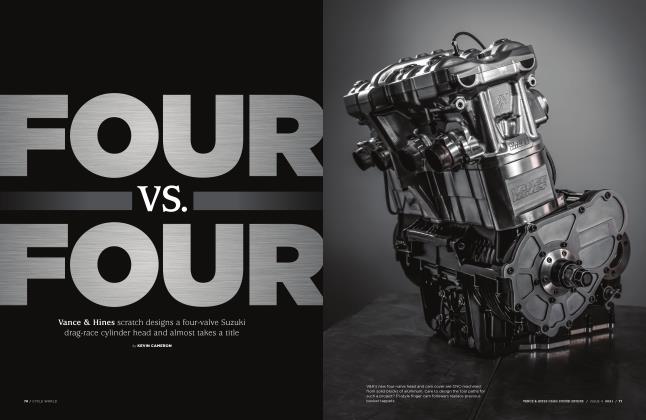

FOUR VS. FOUR

Issue 4 2021 By KEVIN CAMERON -

The COLLECTOR

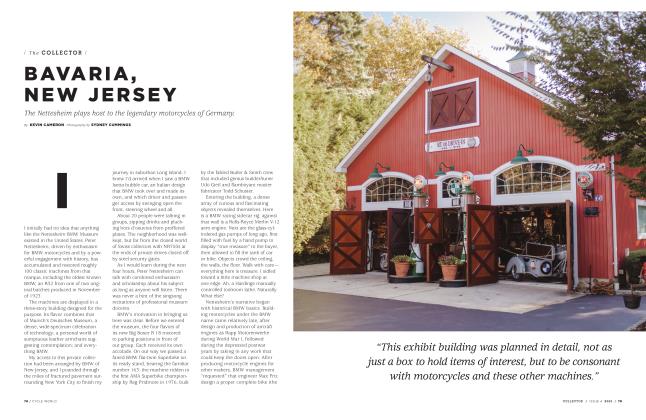

The COLLECTORBAVARIA, NEW JERSEY

Issue 4 2021 By KEVIN CAMERON -

ELEMENTS

ELEMENTSBEAUTIFUL

Issue 4 2021 By KEVIN CAMERON -

UP FRONT

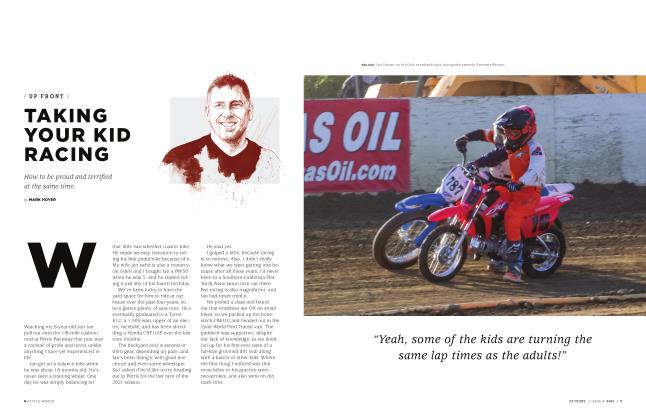

UP FRONTTAKING YOUR KID RACING

Issue 4 2021 By MARK HOYER -

2022 APRILIA TUAREG 660

Issue 4 2021 By Justin Dawes