REALITY CHECK

Is battery capacity charging ahead, or will storing electricity in vehicles remain expensively out of reach?

Can we forecast how and when vehicles with electric drivetrains will make up a significant part of the US market? At present, they make up less than 1 percent, and the most often-cited reasons for this are limited driving range, lack of a convenient nationwide network of charging stations, lengthy charging time, and the high cost of the lithium-ion batteries used for energy storage.

When I went looking for information about this, I found large differences of opinion between battery experts associated with the vehicle business and electric vehicle advocates. This reminded me of the nuclear-power debate of years past, when it was clearthat experts on both sides had attended the same respected graduate schools, had achieved similar academic distinction, yet using the same data, drew conclusions that were 180 degrees apart.

If I read material provided by vehicle industry battery people, Li-ion battery power costs $500 to $650 per kWh.

If the battery in Harley’s prototype electric bike stores 14 kWh, that implies a cost of $7,000 to $9,100. Yet if I talk to electric vehicle advocates, I’m told no, Li-ion is shortly coming right down to $150 to $250 per kWh, which is a price of $2,100 to $3,500. Big difference.

The current estimate from vehicle industry people as to when electrics will achieve whole-vehicle price equality with combustion-powered vehicles is 20 years. Sony commercialized Li-ion in 1991, and one of its experts recently said a high-energy “battery breakthrough”is a 20-year proposition. Yet if I turn again to the visionaries, I am told that is nonsense-everything is happening now, soon.

Is this just the difference between industry, clinging to the old, and the visionaries, reaching for the new? I don’t think so. If Detroit, Toyota, Mercedes, and the others thought they could achieve the new mandated EPA auto mileage standard of 54 mpg most affordably and quickly with electric vehicles, that is what they would develop. Visionaries have little to lose; small start-ups come and go daily. But major industry has to get it right-they are betting the farm. They have looked hard at physics and engineering and have decided to take the hybrid route. There are 120,000 gas stations in the US where it takes two to three minutes to refuel. Typical range for hybrids is 350 to 400 miles pertank. Gasoline engines continue to improve, and their production tooling already exists. They are affordable. Forthe present, this is the direction chosen.

It is also sensible to prototype the alternatives as Harley-Davidson has done because cumulative change in battery price, energy density, and charging time might require a rethink in the future. At 5-percent improvement per year, it takes 14 years to double energy density or cut price by half. At 8 percent, that becomes nine years. I am told that only 1 percent of the cost of Li-ion batteries is materials; the rest is manufacturing and the chargedischarge controls required for safety and maximum life.

Batteries are as good as they are now are because of decades of intensive research. The work continues.

-Kevin Cameron

View Full Issue

View Full Issue

More From This Issue

-

Up Front

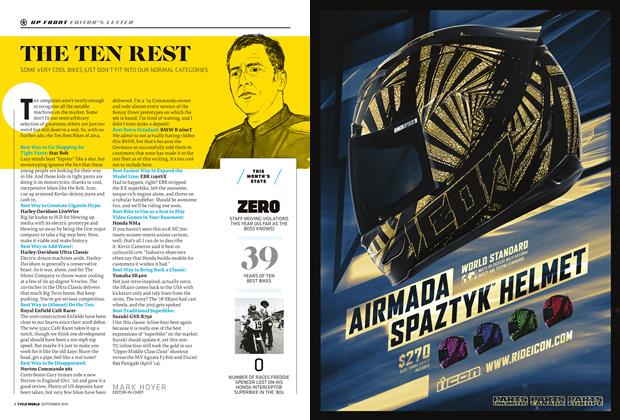

Up FrontThe Ten Rest

September 2014 By Mark Hoyer -

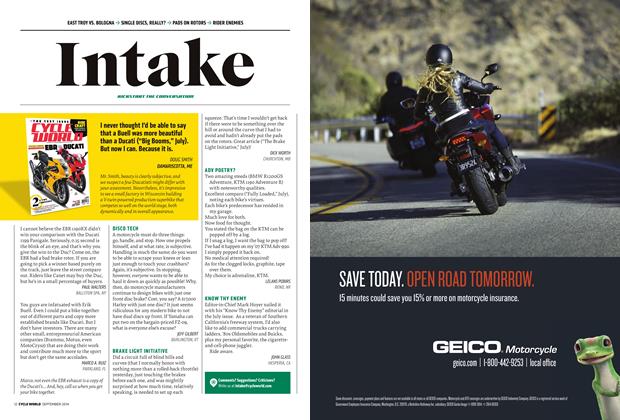

Intake

IntakeIntake

September 2014 -

Ignition

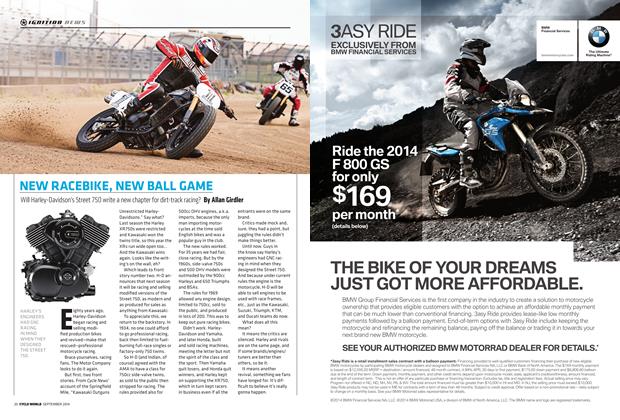

IgnitionNew Racebike, New Ball Game

September 2014 By Allan Girdler -

Ignition

IgnitionThe John Penton Story

September 2014 By Andrew Bornhop -

Ignition

IgnitionYikebike

September 2014 By Blake Conner -

Ignition

IgnitionCw 25 Years Ago September 1989

September 2014 By BC