TDC

Tip-Toeing Through the Tulips

Kevin Cameron

THROUGH THE YEARS 1975-2001, WHEN two-strokes dominated 500cc roadracing, the high power and steep powerbands of those engines forced the development of capable chassis, suspensions and tires. Those emerging technologies, combined through the 1980s with compact and lightweight liquid-cooled four-stroke engines, made the modern high-powered sportbike possible. Even with mufflers, lights and dual seats, these bikes were more capable in every way than pure racebikes of just a few years before. Talk about leveraging your synergies!

A fresh cycle of revolution began in 2002 with the idea that racing motorcycles should cease to be their riders’ enemies and instead become their allies. There had been efforts to implement improved rideability with two-stroke 500s but the results were mixed at best-like putting a comfortable saddle on a saber-toothed cat. The first tool in the new MotoGP revolution was the same one that had made high-power sportbikes rideable by average riders-smooth, predictable torque curves that were easy to use, free of traction-destroying surprises like flat spots closely followed by torque spikes.

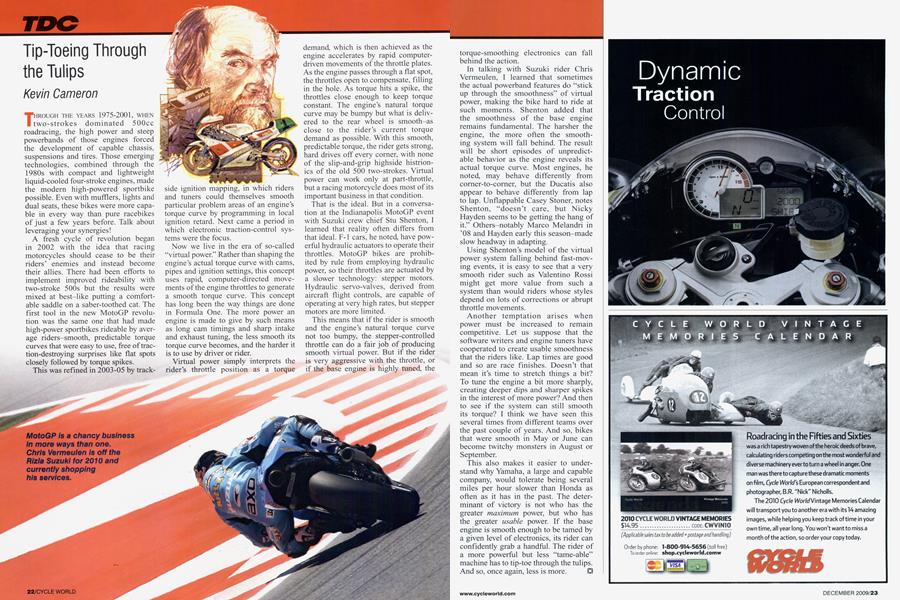

This was refined in 2003-05 by trackside ignition mapping, in which riders and tuners could themselves smooth particular problem areas of an engine’s torque curve by programming in local ignition retard. Next came a period in which electronic traction-control systems were the focus.

Now we live in the era of so-called “virtual power.” Rather than shaping the engine’s actual torque curve with cams, pipes and ignition settings, this concept uses rapid, computer-directed movements of the engine throttles to generate a smooth torque curve. This concept has long been the way things are done in Formula One. The more power an engine is made to give by such means as long cam timings and sharp intake and exhaust tuning, the less smooth its torque curve becomes, and the harder it is to use by driver or rider.

Virtual power simply interprets the rider’s throttle position as a torque demand, which is then achieved as the engine accelerates by rapid computerdriven movements of the throttle plates. As the engine passes through a flat spot, the throttles open to compensate, filling in the hole. As torque hits a spike, the throttles close enough to keep torque constant. The engine’s natural torque curve may be bumpy but what is delivered to the rear wheel is smooth-as close to the rider’s current torque demand as possible. With this smooth, predictable torque, the rider gets strong, hard drives off every corner, with none of the slip-and-grip highside histrionics of the old 500 two-strokes. Virtual power can work only at part-throttle, but a racing motorcycle does most of its important business in that condition.

That is the ideal. But in a conversation at the Indianapolis MotoGP event with Suzuki crew chief Stu Shenton, I learned that reality often differs from that ideal. F-l cars, he noted, have powerful hydraulic actuators to operate their throttles. MotoGP bikes are prohibited by rule from employing hydraulic power, so their throttles are actuated by a slower technology: stepper motors. Hydraulic servo-valves, derived from aircraft flight controls, are capable of operating at very high rates, but stepper motors are more limited.

This means that if the rider is smooth and the engine’s natural torque curve not too bumpy, the stepper-controlled throttle can do a fair job of producing smooth virtual power. But if the rider is very aggressive with the throttle, or if the base engine is highly tuned, the torque-smoothing electronics can fall behind the action.

In talking with Suzuki rider Chris Vermeulen, I learned that sometimes the actual powerband features do “stick up through the smoothness” of virtual power, making the bike hard to ride at such moments. Shenton added that the smoothness of the base engine remains fundamental. The harsher the engine, the more often the smoothing system will fall behind. The result will be short episodes of unpredictable behavior as the engine reveals its actual torque curve. Most engines, he noted, may behave differently from corner-to-corner, but the Ducatis also appear to behave differently from lap to lap. Unflappable Casey Stoner, notes Shenton, “doesn’t care, but Nicky Hayden seems to be getting the hang of it.” Others-notably Marco Melandri in ’08 and Hayden early this season-made slow headway in adapting.

Using Shenton’s model of the virtual power system falling behind fast-moving events, it is easy to see that a very smooth rider such as Valentino Rossi might get more value from such a system than would riders whose styles depend on lots of corrections or abrupt throttle movements.

Another temptation arises when power must be increased to remain competitive. Let us suppose that the software writers and engine tuners have cooperated to create usable smoothness that the riders like. Lap times are good and so are race finishes. Doesn’t that mean it’s time to stretch things a bit? To tune the engine a bit more sharply, creating deeper dips and sharper spikes in the interest of more power? And then to see if the system can still smooth its torque? I think we have seen this several times from different teams over the past couple of years. And so, bikes that were smooth in May or June can become twitchy monsters in August or September.

This also makes it easier to understand why Yamaha, a large and capable company, would tolerate being several miles per hour slower than Honda as often as it has in the past. The determinant of victory is not who has the greater maximum power, but who has the greater usable power. If the base engine is smooth enough to be tamed by a given level of electronics, its rider can confidently grab a handful. The rider of a more powerful but less “tame-able” machine has to tip-toe through the tulips. And so, once again, less is more.

View Full Issue

View Full Issue