Tales of the Testastretta

TDC

Kevin Cameron

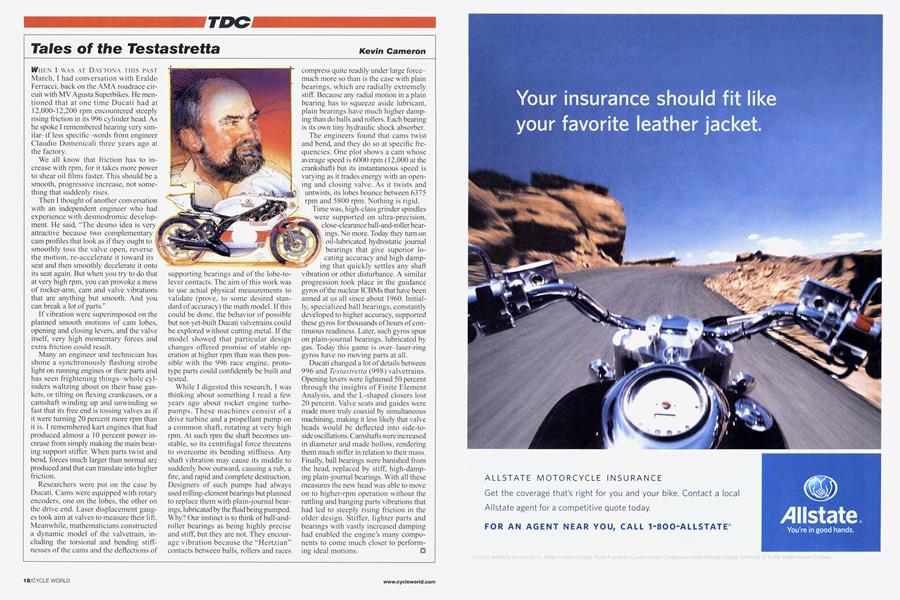

WHEN I WAS AT DAYTONA THIS PAST March, I had conversation with Eraldo Ferracci, back on the AMA roadrace circuit with MV Agusta Superbikes. He mentioned that at one time Ducati had at 12,000-12,200 rpm encountered steeply rising friction in its 996 cylinder head. As he spoke 1 remembered hearing very similar-if less specific-words from engineer Claudio Domenicali three years ago at the factory.

We all know that friction has to increase with rpm, for it takes more power to shear oil films faster. This should be a smooth, progressive increase, not something that suddenly rises.

Then I thought of another conversation with an independent engineer who had experience with desmodromic development. He said, “The desmo idea is very attractive because two complementary cam profiles that look as if they ought to smoothly toss the valve open, reverse the motion, re-accelerate it toward its seat and then smoothly decelerate it onto its seat again. But when you try to do that at very high rpm, you can provoke a mess of rocker-arm, cam and valve vibrations that are anything but smooth. And you can break a lot of parts.”

If vibration were superimposed on the planned smooth motions of cam lobes, opening and closing levers, and the valve itself, very high momentary forces and extra friction could result.

Many an engineer and technician has shone a synchronously flashing strobe light on running engines or their parts and has seen frightening things-whole cylinders waltzing about on their base gaskets, or tilting on flexing crankcases, or a camshaft winding up and unwinding so fast that its free end is tossing valves as if it were turning 20 percent more rpm than it is. I remembered kart engines that had produced almost a 10 percent power increase from simply making the main bearing support stiffer. When parts twist and bend, forces much larger than normal are produced and that can translate into higher friction.

Researchers were put on the case by Ducati. Cams were equipped with rotary encoders, one on the lobes, the other on the drive end. Laser displacement gauges took aim at valves to measure their lift. Meanwhile, mathematicians constructed a dynamic model of the valvetrain, including the torsional and bending stiffnesses of the cams and the deflections of

supporting bearings and of the lobe-tolever contacts. The aim of this work was to use actual physical measurements to validate (prove, to some desired standard of accuracy) the math model. If this could be done, the behavior of possible but not-yet-built Ducati valvetrains could be explored without cutting metal. If the model showed that particular design changes offered promise of stable operation at higher rpm than was then possible with the 996 race engine, prototype parts could confidently be built and tested.

While I digested this research, I was thinking about something I read a few years ago about rocket engine turbopumps. These machines consist of a drive turbine and a propellant pump on a common shaft, rotating at very high rpm. At such rpm the shaft becomes unstable, so its centrifugal force threatens to overcome its bending stiffness. Any shaft vibration may cause its middle to suddenly bow outward, causing a rub, a fire, and rapid and complete destruction. Designers of such pumps had always used rolling-element bearings but planned to replace them with plain-journal bearings, lubricated by the fluid being pumped. Why? Our instinct is to think of ball-androller bearings as being highly precise and stiff, but they are not. They encourage vibration because the “Hertzian” contacts between balls, rollers and races

compress quite readily under large forcemuch more so than is the case with plain bearings, which are radially extremely stiff. Because any radial motion in a plain bearing has to squeeze aside lubricant, plain bearings have much higher damping than do balls and rollers. Each bearing is its own tiny hydraulic shock absorber.

The engineers found that cams twist and bend, and they do so at specific frequencies. One plot shows a cam whose average speed is 6000 rpm (12,000 at the crankshaft) but its instantaneous speed is varying as it trades energy with an opening and closing valve. As it twists and untwists, its lobes bounce between 6375 rpm and 5800 rpm. Nothing is rigid.

Time was, high-class grinder spindles were supported on ultra-precision, close-clearance ball-and-roller bearings. No more. Today they turn on ¡i oil-lubricated hydrostatic journal f bearings that give superior locating accuracy and high damping that quickly settles any shaft vibration or other disturbance. A similar progression took place in the guidance gyros of the nuclear ICBMs that have been aimed at us all since about 1960. Initially, specialized ball bearings, constantly developed to higher accuracy, supported these gyros for thousands of hours of continuous readiness. Later, such gyros spun on plain-journal bearings, lubricated by gas. Today this game is over-laser-ring gyros have no moving parts at all.

Ducati changed a lot of details between 996 and Testastretta (998) valvetrains. Opening levers were lightened 50 percent through the insights of Finite Element Analysis, and the L-shaped closers lost 20 percent. Valve seats and guides were made more truly coaxial by simultaneous machining, making it less likely that valve heads would be deflected into side-toside oscillations. Camshafts were increased in diameter and made hollow, rendering them much stiffer in relation to their mass. Finally, ball bearings were banished from the head, replaced by stiff, high-damping plain-journal bearings. With all these measures the new head was able to move on to higher-rpm operation without the rattling and banging parts vibrations that had led to steeply rising friction in the older design. Stiffer, lighter parts and bearings with vastly increased damping had enabled the engine’s many components to come much closer to performing ideal motions. □

View Full Issue

View Full Issue