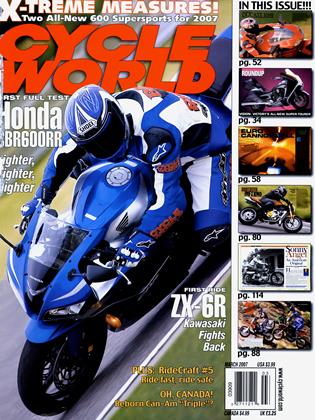

Staff Stuff

This past September, I rode two 2007 Husqvarnas-a TE450 and a TE510-in the Cycle World Trek, a three-day annual industry dual-sport event held in the Sierra Nevada. The TEs, if you don't already know, are full-on, competition-quality enduro bikes that Husqvarna has managed to make 50-state street-legal. I was so impressed with both machines that after the ride, I bought a TE510. And so far, I've been extremely pleased with the bike, which is so

competent as a trailbike that I often forget I can also legally ride it on the road.

Only problem has been the engine's tendency to suddenly and unexpectedly quit when cracking the throttle open a very small amount at idle or just above. At first, I believed this was simply the result of the pilot jetting, which Husqvarna had leaned out to help the TEs meet the current emissions standards. So I swapped the #50 pilot let for a #55, which is what the TC450/ TC51O competition-only models use. That helped, but the motor still would often

spit back through the carb and die when I would jus bump the throttle open a small amount.

I then removed the plastic sidecover on the Keihin carb to check the accelerator-pump operation and saw that the pump rod wasn't being activated until the twistgrip was turned about one-quarter open. No problem, I thought; the pump linkage incorporates an adjustment screw that determines when the rod begins to move. I turned the screw in the direction I thought would activate the pump sooner, but nothing changed. So I turned it in the other direction, but again, nothing changed; no matter what I did with the screw, the rod would not move until the twistgrip was rotated almost a quarter-turn.

I then noticed that when turning the adjustment screw, the relationship between the two relevant parts of the linkage never changed because of a little cap over the end of the screw. Turning the screw simply threaded more or less of the screw's threaded end into the cap; but the cap itself would never move, rendering the screw useless. I then spread the two spring-loaded linkage pieces far enough apart to remove the cap, which just popped right off, and that permitted the end of the screw itself to make contact with the linkage. Bingo! The accelerator pump rod then would move immediately any time the twistgrip was turned, even in response to a tiny little throttle blip. So now, not only does the engine no longer backfire and stall, it's much more crisp and responsive than ever. Evidently, the insertion of that little cap over the adjuster screw was

intended to help the TE pass the requisite emissions tests.

When an accelerator pump squirts fuel into the

intake tract, that gasoline is not nearly as atomized as the fuel mixture that is drawn into the venturi through the regular lets, so it doesn't burn as completely or cleanly. Since the

emissions certification procedure for motorcycles generally results in a disproportionate amount of

emissions being produced between idle and

relatively small throttle openings,

me cap essentiaiiy aisaoiea me accelerator oumn until the

throttle was farther open. Problem solved. No parts required. -Paul Dean