GOING AIRLESS

TIRES ACHIEVE A LARGE, traction-generating footprint by virtue of being a most flexible structure. This arises from the elasticity of rubber and the flexibility and tensile strength of a variety of structural fibers. The tire’s fiber carcass is maintained in tension by inflating with air pressure, so that we can know the footprint’s area to a first approximation by dividing inflation pressure into the load carried.

This is not the only way to create a useful footprint. Michelin’s “bib mousse” makes an off-road tire puncture-proof by using foam rather than air pressure. Industrial trucks roll on solid rubber tires, sometimes rendered more flexible by piercing them with holes. These substitutes for inflation air fail on one point: heat. When you rapidly flex a large mass of rubber, heat is generated. If there is no easy escape route for this heat, it accumulates until the rubber is degenerated by it.

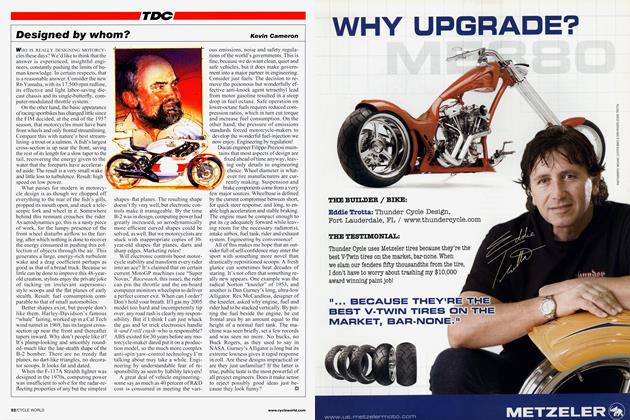

There are now other waysMichelin’s combined car tire/ wheel, cutely named “Tweel,” and an airless scooter tire made up of radial composite

and elastomer reinforcement elements that support a conventional-looking tread. In both cases, the flexible carcass inflated by air is replaced by a flexible grid of urethane and other material. Wrapped around is a band of tread rubber. Because the cells of the flexible grid are open, and because they are made of a material that generates little heat in flexure, the thermal problems of bib mousse or

industrial solid tires are eliminated. Michelin engineers point out that Tweel’s design for the first time allows the lateral stiffness of the “tire” to be several times greater than its vertical stiffnessvery important for delivering quick steering response in an automobile. The airless scooter tire, meanwhile, is conventionally shaped and said to perform like a normal tire. Both concepts are currently in development.

Kevin Cameron