Technology duel

TDC

Kevin Cameron

THERE MUST HAVE BEEN SOMETHING close to desperation at Yamaha after Valentino Rossi reported that both his bike and its Michelin tires performed flawlessly in the Chinese MotoGP-yet Casey Stoner won by 3 seconds on a Bridgestone-shod Ducati. Well, okay, the Shanghai course has the calendar’s longest straight, allowing the super-power Duc to gain an advantage that even Rossi could not retrieve. Maybe when the circus returns to Europe’s “real” tracks, then we’ll see. But motorcycle and tire technology wait for no man.

Rossi may yet win the title, but recent performances have suggested to me that while Bridgestone and Ducati have fashioned secure performance, Yamaha and Michelin have had to push very hard in narrow areas, resulting in high performance that is sensitive to the point of instability. In China, Rossi’s tire worked ( extremely well, but Colin Edwards’ tire did not. At a previous race, both Yamaha riders went well in practice, only to suffer grip loss in the race.

In my mind, I am seeing the current performance of Bridgestone and Ducati as more like a broad hill, while that of Yamaha and Michelin at present seems like a flagpole-just as tall as the hill but with a lot less room on top. Stand anywhere near the top of the hill and your height is about the same. Move even half the width of a foot on top of that flagpole and you fall.

But maybe it’s all in my imagination. Maybe, in my semi-hysterical eagerness for change and new technology, I’m seeing something that’s not there. Thanks to new tire regulations, when they all return to Europe, the little Michelin van will no longer be able to arrive just after sunup each race weekend morning from Clermont-Ferrand, carrying a dozen or so special tires designed and made overnight specifically to solve yesterday’s problems. Maybe that will make more room atop the flagpole-perhaps a comfortable balcony. The status quo ante returns.

Writer Neil Spalding (see Race Watch, page 92)) has revealed recently that Yamaha may be developing a pneumatic-valve cylinder head for the M1 engine, and that in the meantime, shorter, fatter exhaust pipes indicate that peak revs have been raised by 1000 rpm in the interest of more straightaway speed. Some have noted the Yamaha down as much as 12 kph in top speed on the Dues this year. In Rossi’s first year on the Yamaha, such a speed gap (then to the Hondas) could be increasingly made up by the controlled off-corner acceleration uniquely created by the Rossi/Burgess team. In those days, Rossi would say, “Engine delivery is the secret of the lap time.” Today, everyone’s electronics have made their engines’ torque smooth and spike-free. This has equalized off-corner acceleration, making Ducati’s top speed an even greater advantage.

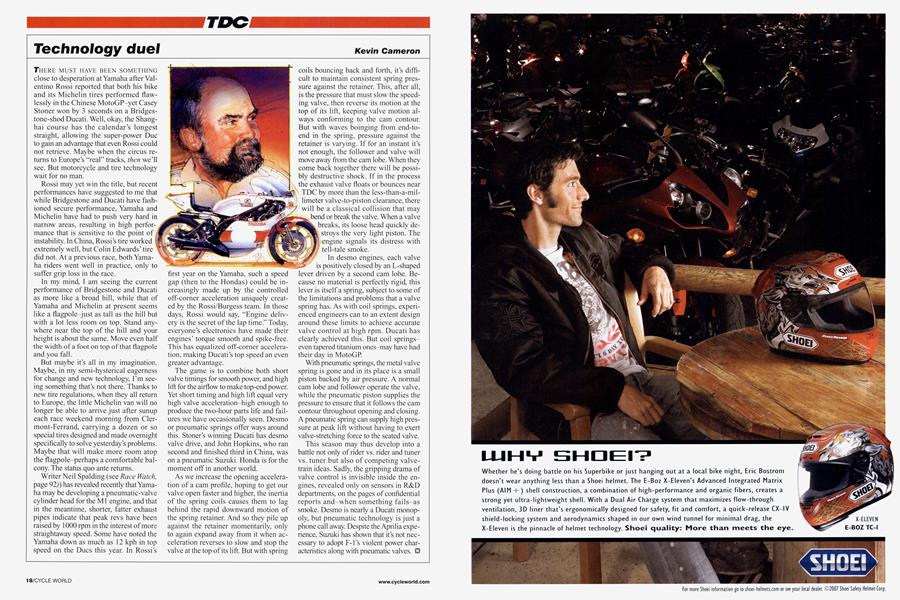

The game is to combine both short valve timings for smooth power, and high lift for the airflow to make top-end power. Yet short timing and high lift equal very high valve acceleration-high enough to produce the two-hour parts life and failures we have occasionally seen. Desmo or pneumatic springs offer ways around this. Stoner’s winning Ducati has desmo valve drive, and John Hopkins, who ran second and finished third in China, was on a pneumatic Suzuki. Honda is for the moment off in another world.

As we increase the opening acceleration of a cam profile, hoping to get our valve open faster and higher, the inertia of the spring coils causes them to lag behind the rapid downward motion of the spring retainer. And so they pile up against the retainer momentarily, only to again expand away from it when acceleration reverses to slow and stop the valve at the top of its lift. But with spring coils bouncing back and forth, it’s difficult to maintain consistent spring pressure against the retainer. This, after all, is the pressure that must slow the speeding valve, then reverse its motion at the top of its lift, keeping valve motion always conforming to the cam contour. But with waves boinging from end-toend in the spring, pressure against the retainer is varying. If for an instant it’s not enough, the follower and valve will move away from the cam lobe. When they come back together there will be possibly destructive shock. If in the process the exhaust valve floats or bounces near TDC by more than the less-than-a-millimeter valve-to-piston clearance, there will be a classical collision that may bend or break the valve. When a valve breaks, its loose head quickly destroys the very light piston. The ¡¡¡engine signals its distress with tell-tale smoke.

In desmo engines, each valve is positively closed by an L-shaped lever driven by a second cam lobe. Because no material is perfectly rigid, this lever is itself a spring, subject to some of the limitations and problems that a valve spring has. As with coil springs, experienced engineers can to an extent design around these limits to achieve accurate valve control at high rpm. Ducati has clearly achieved this. But coil springseven tapered titanium ones-may have had their day in MotoGR

With pneumatic springs, the metal valve spring is gone and in its place is a small piston backed by air pressure. A normal cam lobe and follower operate the valve, while the pneumatic piston supplies the pressure to ensure that it follows the cam contour throughout opening and closing. A pneumatic spring can supply high pressure at peak lift without having to exert valve-stretching force to the seated valve.

This season may thus develop into a battle not only of rider vs. rider and tuner vs. tuner but also of competing valvetrain ideas. Sadly, the gripping drama of valve control is invisible inside the engines, revealed only on sensors in R&D departments, on the pages of confidential reports and-when something fails-as smoke. Desmo is nearly a Ducati monopoly, but pneumatic technology is just a phone call away. Despite the Aprilia experience, Suzuki has shown that it’s not necessary to adopt F-l’s violent power characteristics along with pneumatic valves. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontAnatomy of A Black Eye

September 2007 By David Edwards -

Leanings

LeaningsA Trip To the New Barber

September 2007 By Peter Egan -

Departments

DepartmentsHotshots

September 2007 -

Roundup

RoundupSmaller, Lighter, Faster

September 2007 By Kevin Cameron -

Roundup

Roundup2008 Street Trip

September 2007 By Blake Conner -

Roundup

RoundupEtc.

September 2007