SERVICE

Paul Dean

Cold-blooded flashers

I own a 1984 Honda Gold Wing that has a turnsignal problem. When I first start riding the bike after it has sat unused for a week or even a few days, the turnsignals won’t work. But after I ride for a while-maybe 10 or 15 miles-and the bike warms up, the signals start working and continue to work for the rest of the ride. If I then park the bike for a few days, the same problem occurs. The emergency flashers work properly all the time, so I know that the bulbs and sockets are all right. If you can help, please advise. Dennis Norman

Goodland, Florida

Let ’s try to solve this problem by applying a little deductive reasoning. As you stated, the four-way flashers work, so the turnsignal system ’s lightbulbs and sockets are not the culprits. The fourways use their own separate flasher unit, however, which helps explain why they function when the turnsignals won 't. And since the turnsignals always work once the bike has been ridden a while, there ’s likely nothing wrong with the wiring harness or the handlebar switch. All this points to the turnsignal flasher as the faulty component. The

flasher’s reluctance to perform upon startup could be the result of moisture building up on its 19-year-old contacts while the bike is sitting for several days-a distinct possibility, since you live in a state where humidity is never in short supply. A comparatively brief exposure to heat, vibration or both would help dry out the moisture and allow the

flasher to function again.

The bottom line: Install a new turnsignal flasher. They ’re cheap, easy to replace and readily available. If your Honda dealer doesn’t have one in stock, go to an auto-parts store and pick up a #552 flasher made either by Stant, Federal Mogul or NAPA, all of which have that same part number.

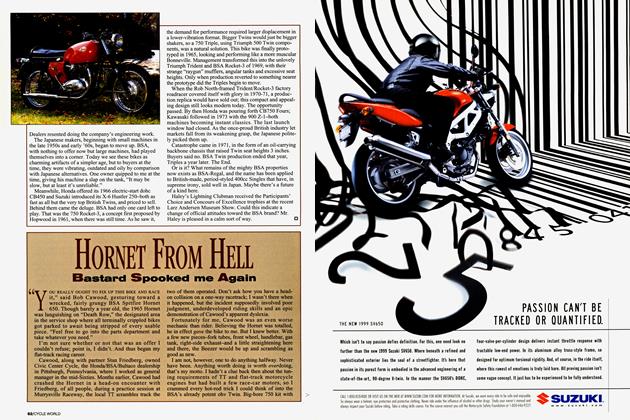

Stop forkin’ around

I own a 1986 Yamaha Radian that I purchased new, and it has been a great bike and an excellent bargain. In 1990, however, I hit a Yugo that poked out from behind a parked garbage truck into my path. The crash bent the stock fork tubes, so I replaced them with tubes from Forking by Frank. They now have gotten scored enough that I have to replace the fork seals, but what do I do about the tubes? The scores are vertical, and some are deep enough that my efforts to polish them out is removing the chrome so that the base metal is peeking through. Will replating work? I’ve called around to platers but still am confused. What do I need, hard chrome, decorative chrome or something else? Paul Dengier Posted on www. cycleworld.com

Don 't cheap out, Paul; what you need is new tubes. After 13 years of faithful service, your Radian deserves nothing less.

I honestly don’t know what type of surface treatment should be applied, but whatever it is, you aren’t likely to get it from a plater who has never worked with motorcycle fork tubes. Aside from needing the proper type of plating, fork tubes have to be finished with precisely the right outside diameter to ensure a proper fit into the slider legs and bushings. Plus, if the tubes are scored deeply enough that some of the base metal is missing, plating is not going to replace it. You ’ll probably end up with tubes that have nice, shiny score marks.

Stock fork tubes for an ’86 Radian would be almost impossible to find, so your best bet is to go back to Frank ’s for replacements. The contact information, just in case you have lost it since 1990, is Frank’s Maintenance and Engineering, Inc., 945 Pitner Ave., Evanston, IL 60202; 847/475-1003.

Shake and brake

My Honda CBR954RR has a vibration that occurs when braking at low speeds. I’ve had two accidents on the bike-one where it hit a curb straight-on, and another when I went over the bars, both at about 40 mph. The bike was repaired by the local shop, but it now vibrates or flexes when the front brake is applied. I disassembled the front end to look for a bad part and found nothing, but I did have trouble sliding the fork tubes back through the triple-clamps; I had to install the left tube first, then kind of flex the right one so it would slip through. The mechanic at the shop said that the steering bearings and wheel bearings are fine, but the front tire has some cupping on it.

Do you have any ideas? Nathan Henry

Austin, Texas

Yeah, I had a few ideas once, but I couldn’t get anyone to listen to them. Seriously, though, your descriptions of the symptoms are sufficiently vague and inconsistent (is something vibrating or flexing?) that any diagnosis I can offer amounts to little more than a WAG (wildass guess). Nonetheless, it would seem that your 954 has a faulty front-brake rotor. During one of your get-offs, the affected rotor may have gotten slightly tweaked-not enough to be visible but enough to cause a pulsing in the front end during braking. Usually, such pulsing is most noticeable at higher speeds, but I have seen instances in which it was felt more at lower speeds. A hard spot or > glazing on the rotor can cause similar symptoms. As far as the tire cupping is concerned, that’s a fairly normal condition with many motorcycles.

Here’s what to do: With the front wheel off the ground, remove the frontbrake calipers and spin the wheel while eyeballing both rotors for any kind of perceptible run-out. If you see any side-to-side movement, that rotor is junk. Even if you don’t see any such movement, you or your mechanic still should check the trueness of the rotor with a dial indicator. If either rotor has more than .012-inch of run-out, replace it.

If the rotors do not exhibit excessive run-out, one or both of them may have a hard or glazed spot. This would cause the braking force to vary momentarily as the pads pass over the affected area of the rotor, resulting in a pulsing that could be felt as a low-frequency vibration. Usually, a thorough sanding of the rotor’s braking surface with a mediumgrit abrasive will remedy the condition; if it doesn’t, rotor replacement is the only alternative.

Recall Roster

NHTSA Campaign No. 03E03700 NexISports NXT “Beanie” Motorcycle Helmets

Model Nos. NB021, NB031, NB041 Dates of manufacture: Oct. 1,2000-June 13,2003

Number of units involved: 46,518 Problem: These helmets fail to comply with Federal Motor Vehicle Safety Standard No. 218 in the areas of impact attenuation, penetration, retention and labeling, and will not adequately protect the wearer in the event of a crash. Serious head injury or death could occur. Remedy: Nexl will notify its customers and, free of charge, rework the helmets to bring them in full compliance with Federal standards. Customers can also contact the National Highway Traffic Safety Administration’s auto safety hotline at 888/327-4236.

By the way, the reason you had to force the right fork tube into place is that either the lower triple-clamp or the tube itself-or both-got bent during a crash. To determine if the fork tube is bent, completely loosen the tripleclamp pinch bolts and try to rotate the tube in the clamp. If it gets alternately harder and easier to turn, it’s bent. The bend would only be very slight, however, so the tube could be safely straightened by someone with a hydraulic press and the knowledge to use it properly. Same goes for the triple-clamp: If it is only marginally out of line, a capable mechanic could lever it back into alignment by using the fork leg as a pry bar. Otherwise, the triple-clamp should be replaced.

Later, stator

I’m desperate for help, and no one seems to have any answers for me. My ’93 Honda CBR900RR sometimes won’t start after I’ve been riding. I replaced the battery, which was 3 years old, but that didn’t help the problem. A few days later, I found that the regulator had a cooked wiring plug, so I replaced the regulator and fixed the plug, but the problem remains. The battery reads 14.5 volts at 2000 rpm, but if I go to 5000, it drops to 14.37 volts and the stator wires glow red in less than a minute. I went to a track day last week, and with all the lights unplugged, nothing got hot, yet 1 can’t find any shorts. Is it possible that the stator is bad? The bike only has 16,000 miles on it, and I don’t want to burn everything up. M. Nerón

Jackson, New Jersey

The first thing you need to do is buy, borrow or steal a shop manual for your 900RR. It will provide you with the instructions—complete with photos, illustrations and values-needed to troubleshoot your electrical system. Without that kind of information, you 're just groping in the dark.

/ don't know whether or not your stator has gone south, but the fact that you simply unplugged the lights and made it through a track day without any difficulties is an indication that the problem lies elsewhere.

You should try checking the battery voltage at various rpm with the lights unplugged to see if the voltage drops and the stator wires glow as the revs rise. If they do not, you 'll know that something in the light> ing system is amiss. If that is the case, you probably can track down the source by keeping an eye on the voltage as you plug in the lights, one by one. When you plug in something that causes the aforementioned symptoms, you ’ll know you have found the gremlin.

High-pressure Ninja

I have a 1987 Kawasaki Ninja 750R that has 35,000 miles on it. The top of the chamber where the oil-filter bolt screws in cracked, so I split the cases and had the lower case welded. Once it was back together, I checked the oil pressure with an automotive gauge and got a reading of more than 100 psi. I then checked the pressure where Kawasaki recommends, at a threaded hole just below the crankshaft, and still got a reading in excess of 100 psi at 7000 rpm. I’ve checked the pressure-relief valve, the oil passages, the lines going to the head and even resplit the cases, and I still can’t find any blockage. Any help would be appreciated. Frank Dlllay

North Huntingdon, Pennsylvania

In all likelihood, your 750R ’s oiling system is just fine and you are getting high pressure readings because you ’re checking the pressure when the oil is cold. Kawasaki stipulates that the pressure should be checked when the oil has been warmed to 194 degrees Fahrenheit. At that temperature, the pressure should be somewhere between 43 and 57psi at 4000 rpm. If you perform the check when the oil is still cold~and do it with the engine running at 7000 rpm-the pressure could easily reach or exceed 100 psi.

Realistically, trying to determine when the oil temperature is at exactly 194 degrees is not very practical. Instead, simply run the engine until it is fully warmed and then check the pressure. Even if the oil is 10 or 15 degrees warmer or cooler than the recommended temperature, the pressure should still fall within the specified limits.

If cold oil proves not to be the cause of the high pressure readings, the problem then is definitely in the operation of the pressure-relief valve, despite your insistence to the contrary. The area of the crankcase that had to be welded is not close enough to the relief valve to have created this condition, so the problem would be in the valve itself or its adjacent bypass. As you no doubt are aware, the valve is a springloaded ball-check located immediately downstream of the oil pump. When the oil pressure reaches a predetermined

Recall Roster

NHTSA Recalls No. 03V228, 0V229 Victory Vegas Model year: 2003 Number of units involved: 1192 Problem: On models with both 49-state and California engine calibrations, the fuel-tank vent line could be plugged, causing potential expulsion of fuel when the fuel cap is opened, Fuel leakage In the presence of an ignition source could result in a fire.

Remedy: Dealers will test the vents and replace any lines that are plugged. Owners who do not receive the free remedy within a reasonable time should contact Victory at 763/417-8650.

level, it pushes the ball off its seat, allowing some of the pumped oil to flow around the valve and through a bypass passage back to the sump, thereby limiting the pressure. If the valve is not opening or something has blocked the bypass, there is no way for the excess oil to escape, rendering the relief valve useless. So, check the valve once again to ensure that it has been correctly assembled and installed in the lower crankcase, and that nothing is blocking the flow of oil back into the sump. If you have any reason to believe that the valve is malfunctioning, simply replace it. □

Got a mechanical or technical problem with your beloved ride? Can’t seem to find workable solutions in your area? Maybe we can help. If you think we can, either: 1) Mail your inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) e-mail it to CW1Dean@aol.com, or 4) log onto www.cycleworld.com and click on the Feedback button. Don’t write a 10-page essay, but do include enough information about the problem to permit a reasonable diagnosis. And please understand that due to the volume of inquiries we receive, we can’t guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Last Harley

October 2003 By David Edwards -

Leanings

LeaningsRevenge of the Soccer Dads

October 2003 By Peter Egan -

TDC

TDCClutch Players

October 2003 By Kevin Cameron -

Departments

DepartmentsHotshots

October 2003 -

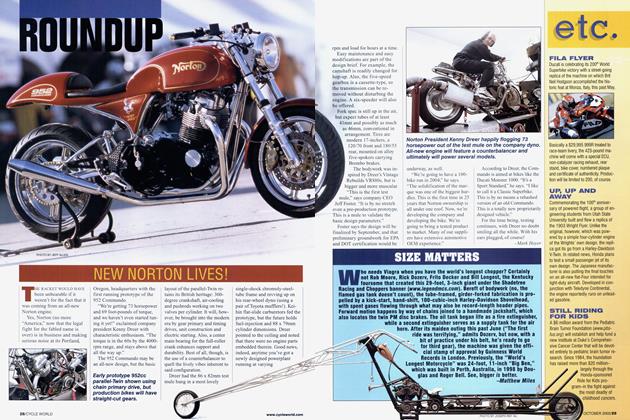

Roundup

RoundupNew Norton Lives!

October 2003 By Mark Hoyer -

Roundup

RoundupSize Matters

October 2003 By Matthew Miles