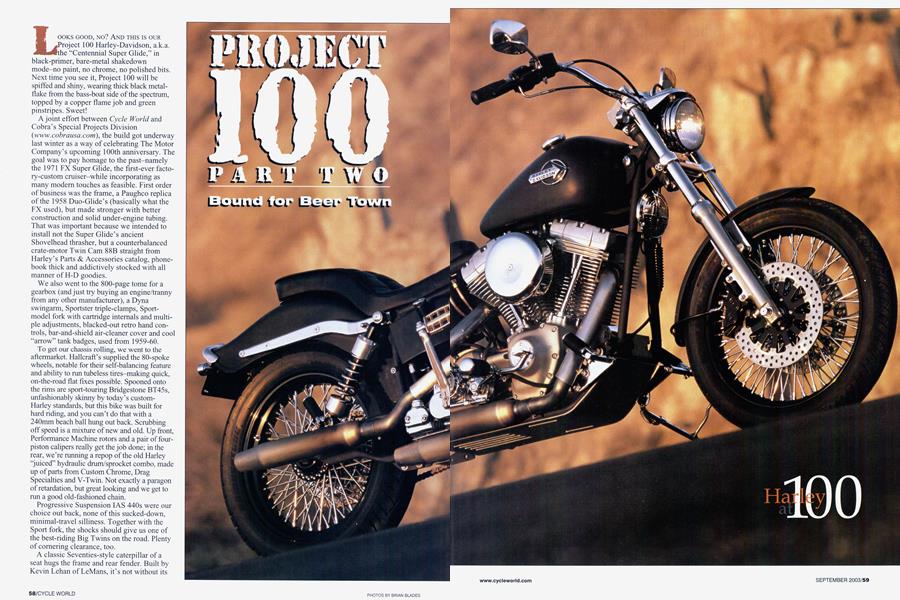

PROJECT 100 PART TWO

Bound for Beer Town

LOOKS GOOD, NO? AND THIS IS OUR Project 100 Harley-Davidson, a.k.a. the "Centennial Super Glide," in black-primer, bare-metal shakedown

mode-no paint, no chrome, no polished bits. Next time you see it, Project 100 will be spiffed and shiny, wearing thick black metalflake from the bass-boat side of the spectrum, topped by a copper flame job and green pinstripes. Sweet!

A joint effort between Cycle World and Cobra’s Special Projects Division (www.cobrausa.com), the build got underway last winter as a way of celebrating The Motor Company’s upcoming 100th anniversary. The goal was to pay homage to the past-namely the 1971 FX Super Glide, the first-ever factory-custom cruiser-while incorporating as many modem touches as feasible. First order of business was the frame, a Paughco replica of the 1958 Duo-Glide’s (basically what the FX used), but made stronger with better construction and solid under-engine tubing. That was important because we intended to install not the Super Glide’s ancient Shovelhead thrasher, but a counterbalanced crate-motor Twin Cam 88B straight from Harley’s Parts & Accessories catalog, phonebook thick and addictively stocked with all manner of H-D goodies.

We also went to the 800-page tome for a gearbox (and just try buying an engine/tranny from any other manufacturer), a Dyna swingarm, Sportster triple-clamps, Sportmodel fork with cartridge internals and multiple adjustments, blacked-out retro hand controls, bar-and-shield air-cleaner cover and cool “arrow” tank badges, used from 1959-60.

To get our chassis rolling, we went to the aftermarket. Hallcraft’s supplied the 80-spoke wheels, notable for their self-balancing feature and ability to mn tubeless tires-making quick, on-the-road flat fixes possible. Spooned onto the rims are sport-touring Bridgestone BT45s, unfashionably skinny by today’s customHarley standards, but this bike was built for hard riding, and you can’t do that with a 240mm beach ball hung out back. Scrubbing off speed is a mixture of new and old. Up front, Performance Machine rotors and a pair of fourpiston calipers really get the job done; in the rear, we’re running a repop of the old Harley “juiced” hydraulic drum/sprocket combo, made up of parts from Custom Chrome, Drag Specialties and V-Twin. Not exactly a paragon of retardation, but great looking and we get to run a good old-fashioned chain.

Progressive Suspension IAS 440s were our choice out back, none of this sucked-down, minimal-travel silliness. Together with the Sport fork, the shocks should give us one of the best-riding Big Twins on the road. Plenty of cornering clearance, too.

A classic Seventies-style caterpillar of a seat hugs the frame and rear fender. Built by Kevin Lehan of LeMans, it’s not without its own mod-cons, as in gel inserts and a ballistics-tough expanded-urethane cover. A row of ’68 Chevelle chromed upholstery buttons (just like Fonda’s Captain America!) finishes things off. Riding position is old-school sit-up-andbeg; great around town, not so on the open road-hence the highway pegs.

Harley at 100

Cobra’s fab-master Denny Berg is the man in charge of the Project 100 build. Knowing that the bike’s debut would not be on a revolving pedestal at some show, but on a rural two-lane, leading CW readers on a Lotus Tours-organized “Backroads to Milwaukee” run bound for the big 100th birthday doings in Beer Town, he put 250 no-mercy shakedown miles on the mockup. “It’s built like an endurance roadracer,” he says. Got a little dirtbike in it, too. Note the sheet aluminum “skidplate.” Originally intended to protect an under-tranny oilcooler Berg plumbed in, its dimensions grew. Explains Denny, “Hey, you never

know when you might want to do a little off-roading...”

As this is being written, Project 100’s various components are in orbit-tinware at Zeaks Design for paint, pipes (custom headers and, of course, Cobra shorty duals) at the platers, engine in the capable hands of Herman Gould of Herman’s Heads for some portwork, plus cams and a valve-spring kit from Screamin’ Eagle. And, yes, booting the two 725cc pistons to life via the Custom Chrome kickstarter kit (like the original FX, there’s no electric leg) is an acquired skill, though the Mikuni HSR43 carb and Zippers programmable ignition have thankfully kept kickbacks to a minimum.

As you read this, our Centennial Super Glide is hammer down, somewhere between SoCal and Wisconsin. See ya in Milwaukee? David Edwards

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Last Harley

October 2003 By David Edwards -

Leanings

LeaningsRevenge of the Soccer Dads

October 2003 By Peter Egan -

TDC

TDCClutch Players

October 2003 By Kevin Cameron -

Departments

DepartmentsHotshots

October 2003 -

Roundup

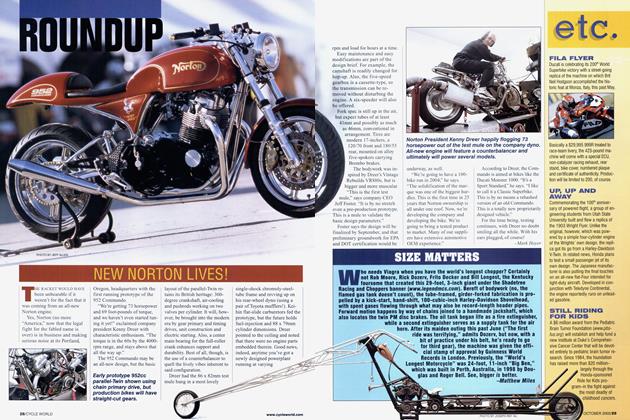

RoundupNew Norton Lives!

October 2003 By Mark Hoyer -

Roundup

RoundupSize Matters

October 2003 By Matthew Miles