Screwed and shrunk

TDC

Kevin Cameron

ALL MOTORCYCLE ENGINES ARE AIRcooled. Some are directly so by air passing over extensions of engine surface called fins. Others are indirectly air-cooled-their heat is carried away by a liquid-phase heat exchange medium (water or water/antifreeze mixtures) to a liquid-to-air heat exchanger called a radiator.

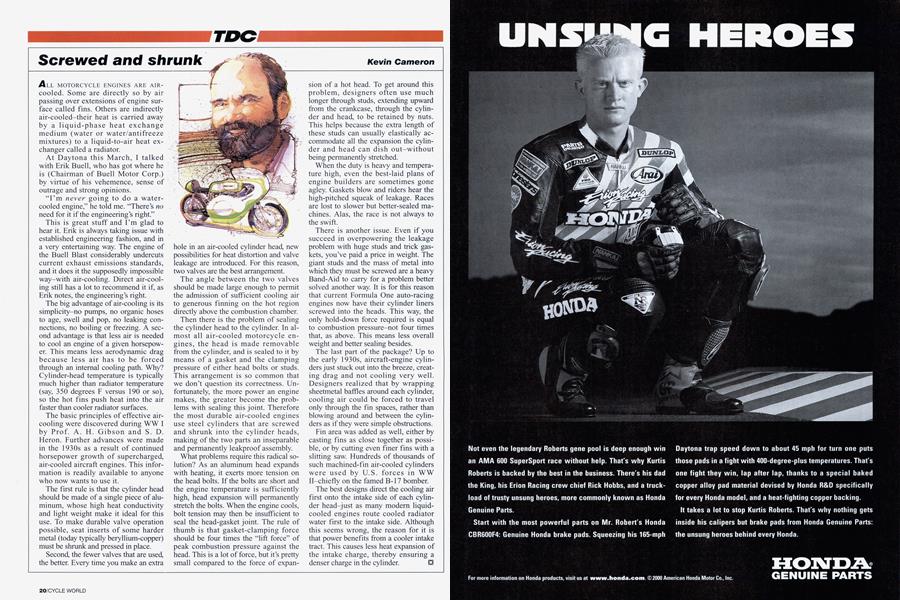

At Daytona this March, I talked with Erik Buell, who has got where he is (Chairman of Buell Motor Corp.) by virtue of his vehemence, sense of outrage and strong opinions.

“I’m never going to do a watercooled engine,” he told me. “There’s no need for it if the engineering’s right.”

This is great stuff and I’m glad to hear it. Erik is always taking issue with established engineering fashion, and in a very entertaining way. The engine of the Buell Blast considerably undercuts current exhaust emissions standards, and it does it the supposedly impossible way-with air-cooling. Direct air-cooling still has a lot to recommend it if, as Erik notes, the engineering’s right.

The big advantage of air-cooling is its simplicity-no pumps, no organic hoses to age, swell and pop, no leaking connections, no boiling or freezing. A second advantage is that less air is needed to cool an engine of a given horsepower. This means less aerodynamic drag because less air has to be forced through an internal cooling path. Why? Cylinder-head temperature is typically much higher than radiator temperature (say, 350 degrees F versus 190 or so), so the hot fins push heat into the air faster than cooler radiator surfaces.

The basic principles of effective aircooling were discovered during WW I by Prof. A. H. Gibson and S. D. Heron. Further advances were made in the 1930s as a result of continued horsepower growth of supercharged, air-cooled aircraft engines. This information is readily available to anyone who now wants to use it.

The first rule is that the cylinder head should be made of a single piece of aluminum, whose high heat conductivity and light weight make it ideal for this use. To make durable valve operation possible, seat inserts of some harder metal (today typically beryllium-copper) must be shrunk and pressed in place.

Second, the fewer valves that are used, the better. Every time you make an extra

hole in an air-cooled cylinder head, new possibilities for heat distortion and valve leakage are introduced. For this reason, two valves are the best arrangement.

The angle between the two valves should be made large enough to permit the admission of sufficient cooling air to generous finning on the hot region directly above the combustion chamber.

Then there is the problem of sealing the cylinder head to the cylinder. In almost all air-cooled motorcycle engines, the head is made removable from the cylinder, and is sealed to it by means of a gasket and the clamping pressure of either head bolts or studs. This arrangement is so common that we don’t question its correctness. Unfortunately, the more power an engine makes, the greater become the problems with sealing this joint. Therefore the most durable air-cooled engines use steel cylinders that are screwed and shrunk into the cylinder heads, making of the two parts an inseparable and permanently leakproof assembly.

What problems require this radical solution? As an aluminum head expands with heating, it exerts more tension on the head bolts. If the bolts are short and the engine temperature is sufficiently high, head expansion will permanently stretch the bolts. When the engine cools, bolt tension may then be insufficient to seal the head-gasket joint. The rule of thumb is that gasket-clamping force should be four times the “lift force” of peak combustion pressure against the head. This is a lot of force, but it’s pretty small compared to the force of expan-

sion of a hot head. To get around this problem, designers often use much longer through studs, extending upward from the crankcase, through the cylinder and head, to be retained by nuts. This helps because the extra length of these studs can usually elastically accommodate all the expansion the cylinder and head can dish out-without being permanently stretched.

When the duty is heavy and temperature high, even the best-laid plans of engine builders are sometimes gone agley. Gaskets blow and riders hear the high-pitched squeak of leakage. Races are lost to slower but better-sealed machines. Alas, the race is not always to the swift.

There is another issue. Even if you succeed in overpowering the leakage problem with huge studs and trick gaskets, you’ve paid a price in weight. The giant studs and the mass of metal into which they must be screwed are a heavy Band-Aid to carry for a problem better solved another way. It is for this reason that current Formula One auto-racing engines now have their cylinder liners screwed into the heads. This way, the only hold-down force required is equal to combustion pressure-not four times that, as above. This means less overall weight and better sealing besides.

The last part of the package? Up to the early 1930s, aircraft-engine cylinders just stuck out into the breeze, creating drag and not cooling very well. Designers realized that by wrapping sheetmetal baffles around each cylinder, cooling air could be forced to travel only through the fin spaces, rather than blowing around and between the cylinders as if they were simple obstructions.

Fin area was added as well, either by casting fins as close together as possible, or by cutting even finer fins with a slitting saw. Hundreds of thousands of such machined-fin air-cooled cylinders were used by U.S. forces in WW II—chiefly on the famed B-17 bomber.

The best designs direct the cooling air first onto the intake side of each cylinder head-just as many modern liquidcooled engines route cooled radiator water first to the intake side. Although this seems wrong, the reason for it is that power benefits from a cooler intake tract. This causes less heat expansion of the intake charge, thereby ensuring a denser charge in the cylinder. □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontMr. Bonneville

September 2000 By David Edwards -

Leanings

LeaningsCafé Americano

September 2000 By Peter Egan -

Departments

DepartmentsHotshots

September 2000 -

Roundup

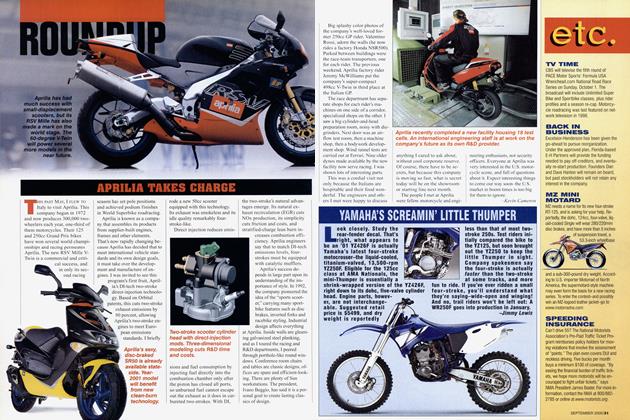

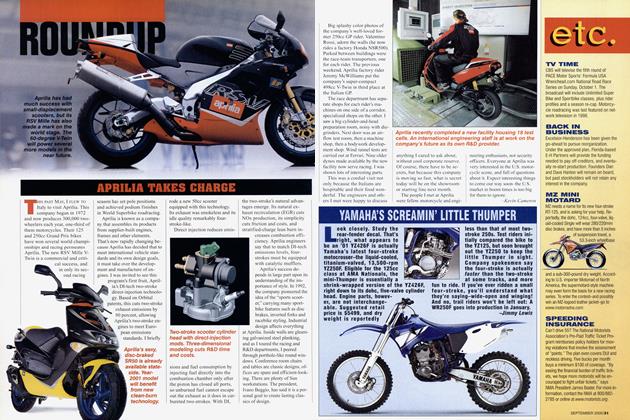

RoundupAprilia Takes Charge

September 2000 By Kevin Cameron -

Roundup

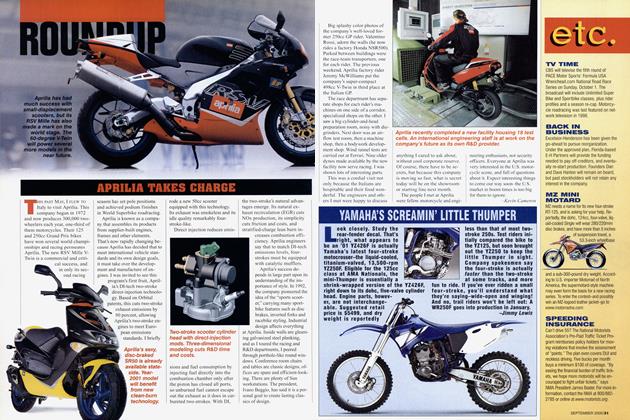

RoundupYamaha's Screamin' Little Thumper

September 2000 By Jimmy Lewis -

Roundup

RoundupEtc.

September 2000