Counting cracks

TDC

Kevin Cameron

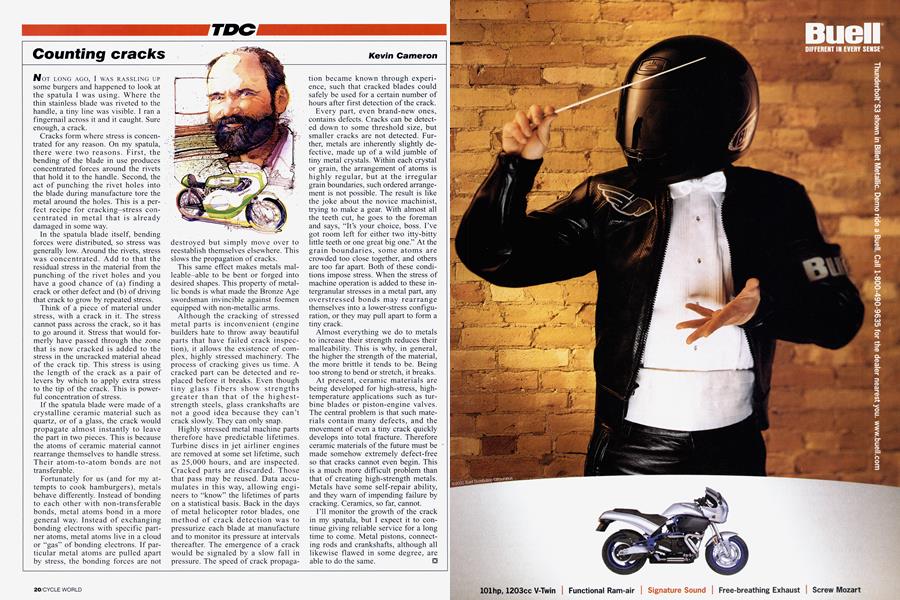

NOT LONG AGO, I WAS RASSLING UP some burgers and happened to look at the spatula I was using. Where the thin stainless blade was riveted to the handle, a tiny line was visible. I ran a fingernail across it and it caught. Sure enough, a crack.

Cracks form where stress is concentrated for any reason. On my spatula, there were two reasons. First, the bending of the blade in use produces concentrated forces around the rivets that hold it to the handle. Second, the act of punching the rivet holes into the blade during manufacture tore the metal around the holes. This is a perfect recipe for cracking-stress concentrated in metal that is already damaged in some way.

In the spatula blade itself, bending forces were distributed, so stress was generally low. Around the rivets, stress was concentrated. Add to that the residual stress in the material from the punching of the rivet holes and you have a good chance of (a) finding a crack or other defect and (b) of driving that crack to grow by repeated stress.

Think of a piece of material under stress, with a crack in it. The stress cannot pass across the crack, so it has to go around it. Stress that would formerly have passed through the zone that is now cracked is added to the stress in the uncracked material ahead of the crack tip. This stress is using the length of the crack as a pair of levers by which to apply extra stress to the tip of the crack. This is powerful concentration of stress.

If the spatula blade were made of a crystalline ceramic material such as quartz, or of a glass, the crack would propagate almost instantly to leave the part in two pieces. This is because the atoms of ceramic material cannot rearrange themselves to handle stress. Their atom-to-atom bonds are not transferable.

Fortunately for us (and for my attempts to cook hamburgers), metals behave differently. Instead of bonding to each other with non-transferable bonds, metal atoms bond in a more general way. Instead of exchanging bonding electrons with specific partner atoms, metal atoms live in a cloud or “gas” of bonding electrons. If particular metal atoms are pulled apart by stress, the bonding forces are not

destroyed but simply move over to reestablish themselves elsewhere. This slows the propagation of cracks.

This same effect makes metals malleable-able to be bent or forged into desired shapes. This property of metallic bonds is what made the Bronze Age swordsman invincible against foemen equipped with non-metallic arms.

Although the cracking of stressed metal parts is inconvenient (engine builders hate to throw away beautiful parts that have failed crack inspection), it allows the existence of complex, highly stressed machinery. The process of cracking gives us time. A cracked part can be detected and replaced before it breaks. Even though tiny glass fibers show strengths greater than that of the higheststrength steels, glass crankshafts are not a good idea because they can’t crack slowly. They can only snap.

Highly stressed metal machine parts therefore have predictable lifetimes. Turbine discs in jet airliner engines are removed at some set lifetime, such as 25,000 hours, and are inspected. Cracked parts are discarded. Those that pass may be reused. Data accumulates in this way, allowing engineers to “know” the lifetimes of parts on a statistical basis. Back in the days of metal helicopter rotor blades, one method of crack detection was to pressurize each blade at manufacture and to monitor its pressure at intervals thereafter. The emergence of a crack would be signaled by a slow fall in pressure. The speed of crack propaga-

tion became known through experience, such that cracked blades could safely be used for a certain number of hours after first detection of the crack.

Every part, even brand-new ones, contains defects. Cracks can be detected down to some threshold size, but smaller cracks are not detected. Further, metals are inherently slightly defective, made up of a wild jumble of tiny metal crystals. Within each crystal or grain, the arrangement of atoms is highly regular, but at the irregular grain boundaries, such ordered arrangement is not possible. The result is like the joke about the novice machinist, trying to make a gear. With almost all the teeth cut, he goes to the foreman and says, “It’s your choice, boss. I’ve got room left for either two itty-bitty little teeth or one great big one.” At the grain boundaries, some atoms are crowded too close together, and others are too far apart. Both of these conditions impose stress. When the stress of machine operation is added to these intergranular stresses in a metal part, any overstressed bonds may rearrange themselves into a lower-stress configuration, or they may pull apart to form a tiny crack.

Almost everything we do to metals to increase their strength reduces their malleability. This is why, in general, the higher the strength of the material, the more brittle it tends to be. Being too strong to bend or stretch, it breaks.

At present, ceramic materials are being developed for high-stress, hightemperature applications such as turbine blades or piston-engine valves. The central problem is that such materials contain many defects, and the movement of even a tiny crack quickly develops into total fracture. Therefore ceramic materials of the future must be made somehow extremely defect-free so that cracks cannot even begin. This is a much more difficult problem than that of creating high-strength metals. Metals have some self-repair ability, and they warn of impending failure by cracking. Ceramics, so far, cannot.

I’ll monitor the growth of the crack in my spatula, but I expect it to continue giving reliable service for a long time to come. Metal pistons, connecting rods and crankshafts, although all likewise flawed in some degree, are able to do the same.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontThe Ten Rest, 2000

July 2000 By David Edwards -

Leanings

LeaningsThe Perfect Baja Bike

July 2000 By Peter Egan -

Departments

DepartmentsHotshots

July 2000 -

Roundup

RoundupFriedel Münch Strikes Again

July 2000 By Kevin Cameron -

Roundup

RoundupAprilia Buys Moto Guzzi

July 2000 By Bruno De Prato -

Roundup

RoundupBandit 1200s Makeover

July 2000