G spots

Kevin Cameron

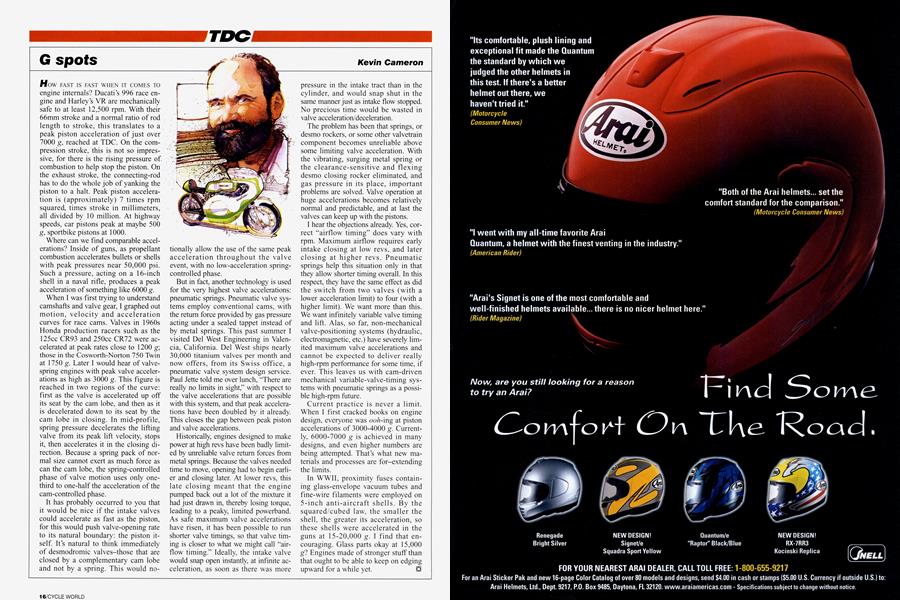

TDC

HOW FAST IS FAST WHEN IT COMES TO engine internals? Ducati's 996 race engine and Harley's VR are mechanically safe to at least 12,500 rpm. With their 66mm stroke and a normal ratio of rod length to stroke, this translates to a peak piston acceleration of just over 7000 g, reached at TDC. On the compression stroke, this is not so impressive, for there is the rising pressure of. combustion to help stop the piston. On the exhaust stroke, the connecting-rod has to do the whole job of yanking the piston to a halt. Peak piston acceleration is (approximately) 7 times rpm squared, times stroke in millimeters, all divided by 10 million. At highway speeds, car pistons peak at maybe 500 g, sportbike pistons at 1000.

Where can we find comparable accelerations? Inside of guns, as propellant combustion accelerates bullets or shells with peak pressures near 50,000 psi. Such a pressure, acting on a 16-inch shell in a naval rifle, produces a peak acceleration of something like 6000 g.

When I was first trying to understand camshafts and valve gear, I graphed out motion, velocity and acceleration curves for race cams. Valves in 1960s Honda production racers such as the 125cc CR93 and 250cc CR72 were accelerated at peak rates close to 1200 g; those in the Cosworth-Norton 750 Twin at 1750 g. Later I would hear of valvespring engines with peak valve accelerations as high as 3000 g. This figure is reached in two regions of the curve: first as the valve is accelerated up off its seat by the cam lobe, and then as it is decelerated down to its seat by the cam lobe in closing. In mid-profile, spring pressure decelerates the lifting valve from its peak lift velocity, stops it, then accelerates it in the closing direction. Because a spring pack of normal size cannot exert as much force as can the cam lobe, the spring-controlled phase of valve motion uses only onethird to one-half the acceleration of the cam-controlled phase.

It has probably occurred to you that it would be nice if the intake valves could accelerate as fast as the piston, for this would push valve-opening rate to its natural boundary: the piston itself. It's natural to think immediately of desmodromic valves-those that are closed by a complementary cam lobe and not by a spring. This would no-

tionally allow the use of the same peak acceleration throughout the valve event, with no low-acceleration springcontrolled phase.

But in fact, another technology is used for the very highest valve accelerations: pneumatic springs. Pneumatic valve systems employ conventional cams, with the return force provided by gas pressure acting under a sealed tappet instead of by metal springs. This past summer I visited Del West Engineering in Valencia, California. Del West ships nearly 30,000 titanium valves per month and now offers, from its Swiss office, a pneumatic valve system design service. Paul Jette told me over lunch, "There are really no limits in sight," with respect to the valve accelerations that are possible with this system, and that peak accelerations have been doubled by it already. This closes the gap between peak piston and valve accelerations.

Historically, engines designed to make power at high revs have been badly limited by unreliable valve return forces from metal springs. Because the valves needed time to move, opening had to begin earlier and closing later. At lower revs, this late closing meant that the engine pumped back out a lot of the mixture it had just drawn in, thereby losing torque, leading to a peaky, limited powerband. As safe maximum valve accelerations have risen, it has been possible to run shorter valve timings, so that valve timing is closer to what we might call "airflow timing." Ideally, the intake valve would snap open instantly, at infinite acceleration, as soon as there was more

pressure in the intake tract than in the cylinder, and would snap shut in the same manner just as intake flow stopped. No precious time would be wasted in valve acceleration/deceleration.

The problem has been that springs, or desmo rockers, or some other valvetrain component becomes unreliable above some limiting valve acceleration. With the vibrating, surging metal spring or the clearance-sensitive and flexing desmo closing rocker eliminated, and gas pressure in its place, important problems are solved. Valve operation at huge accelerations becomes relatively normal and predictable, and at last the valves can keep up with the pistons.

I hear the objections already. Yes, correct "airflow timing" does vary with rpm. Maximum airflow requires early intake closing at low revs, and later closing at higher revs. Pneumatic springs help this situation only in that they allow shorter timing overall. In this respect, they have the same effect as did the switch from two valves (with a lower acceleration limit) to four (with a higher limit). We want more than this. We want infinitely variable valve timing and lift. Alas, so far, non-mechanical valve-positioning systems (hydraulic, electromagnetic, etc.) have severely limited maximum valve accelerations and cannot be expected to deliver really high-rpm performance for some time, if ever. This leaves us with cam-driven mechanical variable-valve-timing systems with pneumatic springs as a possible high-rpm future.

Current practice is never a limit. When I first cracked books on engine design, everyone was 00/7-ing at piston accelerations of 3000-4000 g. Currently, 6000-7000 g is achieved in many designs, and even higher numbers are being attempted. That's what new materials and processes are for-extending the limits.

In WWII, proximity fuses containing glass-envelope vacuum tubes and fine-wire filaments were employed on 5-inch anti-aircraft shells. By the squared/cubed law, the smaller the shell, the greater its acceleration, so these shells were accelerated in the guns at 15-20,000 g. I find that encouraging. Glass parts okay at 15,000 g? Engines made of stronger stuff than that ought to be able to keep on edging upward for a while yet. □