TDC

Plight of the wristpin

Kevin Cameron

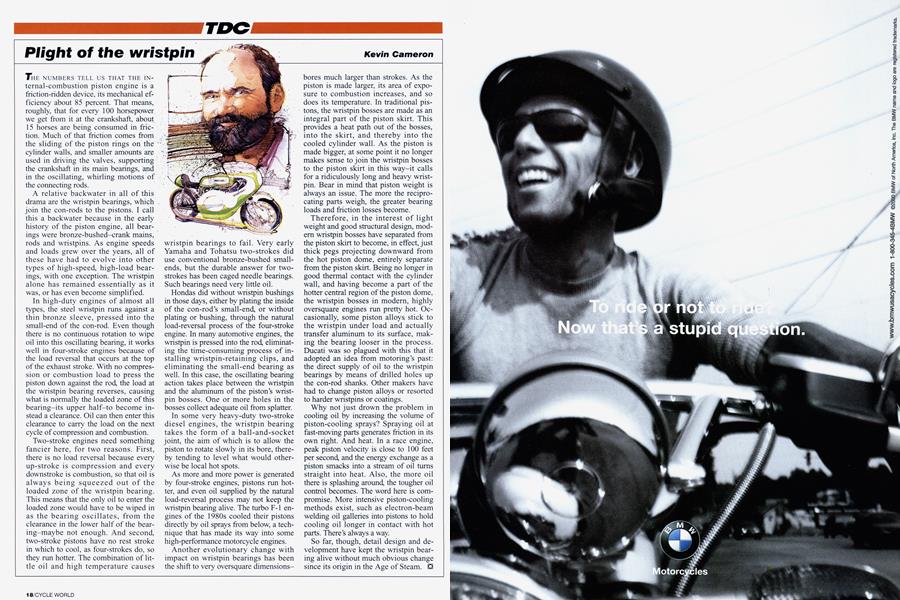

THE NUMBERS TELL US THAT THE INternal-combustion piston engine is a friction-ridden device, its mechanical efficiency about 85 percent. That means, roughly, that for every 100 horsepower we get from it at the crankshaft, about 15 horses are being consumed in friction. Much of that friction comes from the sliding of the piston rings on the cylinder walls, and smaller amounts are used in driving the valves, supporting the crankshaft in its main bearings, and in the oscillating, whirling motions of the connecting rods.

A relative backwater in all of this drama are the wristpin bearings, which join the con-rods to the pistons. I call this a backwater because in the early history of the piston engine, all bearings were bronze-bushed-crank mains, rods and wristpins. As engine speeds and loads grew over the years, all of these have had to evolve into other types of high-speed, high-load bearings, with one exception. The wristpin alone has remained essentially as it was, or has even become simplified.

In high-duty engines of almost all types, the steel wristpin runs against a thin bronze sleeve, pressed into the small-end of the con-rod. Even though there is no continuous rotation to wipe oil into this oscillating bearing, it works well in four-stroke engines because of the load reversal that occurs at the top of the exhaust stroke. With no compression or combustion load to press the piston down against the rod, the load at the wristpin bearing reverses, causing what is normally the loaded zone of this bearing-its upper half-to become instead a clearance. Oil can then enter this clearance to carry the load on the next cycle of compression and combustion.

Two-stroke engines need something fancier here, for two reasons. First, there is no load reversal because every up-stroke is compression and every downstroke is combustion, so that oil is always being squeezed out of the loaded zone of the wristpin bearing. This means that the only oil to enter the loaded zone would have to be wiped in as the bearing oscillates, from the clearance in the lower half of the bearing-maybe not enough. And second, two-stroke pistons have no rest stroke in which to cool, as four-strokes do, so they run hotter. The combination of little oil and high temperature causes

wristpin bearings to fail. Very early Yamaha and Tohatsu two-strokes did use conventional bronze-bushed smallends, but the durable answer for twostrokes has been caged needle bearings. Such bearings need very little oil.

Hondas did without wristpin bushings in those days, either by plating the inside of the con-rod’s small-end, or without plating or bushing, through the natural load-reversal process of the four-stroke engine. In many automotive engines, the wristpin is pressed into the rod, eliminating the time-consuming process of installing wristpin-retaining clips, and eliminating the small-end bearing as well. In this case, the oscillating bearing action takes place between the wristpin and the aluminum of the piston’s wristpin bosses. One or more holes in the bosses collect adequate oil from splatter.

In some very heavy-duty two-stroke diesel engines, the wristpin bearing takes the form of a ball-and-socket joint, the aim of which is to allow the piston to rotate slowly in its bore, thereby tending to level what would otherwise be local hot spots.

As more and more power is generated by four-stroke engines, pistons run hotter, and even oil supplied by the natural load-reversal process may not keep the wristpin bearing alive. The turbo F-l engines of the 1980s cooled their pistons directly by oil sprays from below, a technique that has made its way into some high-performance motorcycle engines.

Another evolutionary change with impact on wristpin bearings has been the shift to very oversquare dimensions-

bores much larger than strokes. As the piston is made larger, its area of exposure to combustion increases, and so does its temperature. In traditional pistons, the wristpin bosses are made as an integral part of the piston skirt. This provides a heat path out of the bosses, into the skirt, and thereby into the cooled cylinder wall. As the piston is made bigger, at some point it no longer makes sense to join the wristpin bosses to the piston skirt in this way-it calls for a ridiculously long and heavy wristpin. Bear in mind that piston weight is always an issue. The more the reciprocating parts weigh, the greater bearing loads and friction losses become.

Therefore, in the interest of light weight and good structural design, modem wristpin bosses have separated from the piston skirt to become, in effect, just thick pegs projecting downward from the hot piston dome, entirely separate from the piston skirt. Being no longer in good thermal contact with the cylinder wall, and having become a part of the hotter central region of the piston dome, the wristpin bosses in modern, highly oversquare engines run pretty hot. Occasionally, some piston alloys stick to the wristpin under load and actually transfer aluminum to its surface, making the bearing looser in the process. Ducati was so plagued with this that it adopted an idea from motoring’s past: the direct supply of oil to the wristpin bearings by means of drilled holes up the con-rod shanks. Other makers have had to change piston alloys or resorted to harder wristpins or coatings.

Why not just drown the problem in cooling oil by increasing the volume of piston-cooling sprays? Spraying oil at fast-moving parts generates friction in its own right. And heat. In a race engine, peak piston velocity is close to 100 feet per second, and the energy exchange as a piston smacks into a stream of oil turns straight into heat. Also, the more oil there is splashing around, the tougher oil control becomes. The word here is compromise. More intensive piston-cooling methods exist, such as electron-beam welding oil galleries into pistons to hold cooling oil longer in contact with hot parts. There’s always a way.

So far, though, detail design and development have kept the wristpin bearing alive without much obvious change since its origin in the Age of Steam.