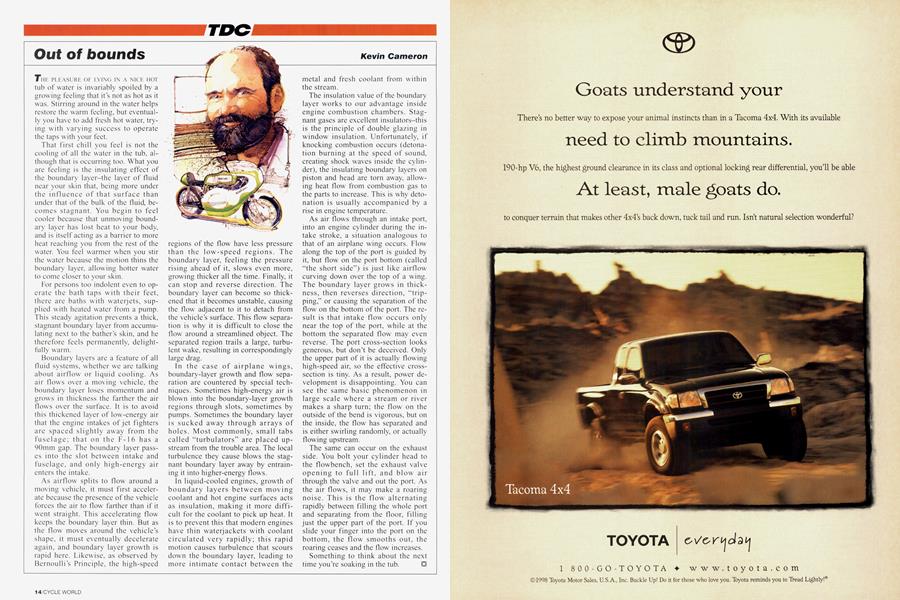

Out of bounds

TDC

Kevin Cameron

THE PLEASURE OF LYING IN A NICE HOT tub of water is invariably spoiled by a growing feeling that it’s not as hot as it was. Stirring around in the water helps restore the warm feeling, but eventually you have to add fresh hot water, trying with varying success to operate the taps with your feet.

That first chill you feel is not the cooling of all the water in the tub, although that is occurring too. What you are feeling is the insulating effect of the boundary layer-the layer of fluid near your skin that, being more under the influence of that surface than under that of the bulk of the fluid, becomes stagnant. You begin to feel cooler because that unmoving boundary layer has lost heat to your body, and is itself acting as a barrier to more heat reaching you from the rest of the water. You feel warmer when you stir the water because the motion thins the boundary layer, allowing hotter water to come closer to your skin.

For persons too indolent even to operate the bath taps with their feet, there are baths with waterjets, supplied w ith heated water from a pump. This steady agitation prevents a thick, stagnant boundary layer from accumulating next to the bather’s skin, and he therefore feels permanently, delightfully warm.

Boundary layers are a feature of all fluid systems, whether we are talking about airflow or liquid cooling. As air flows over a moving vehicle, the boundary layer loses momentum and grows in thickness the farther the air flows over the surface. It is to avoid this thickened layer of low-energy air that the engine intakes of jet fighters are spaced slightly away from the fuselage; that on the F-16 has a 90mm gap. The boundary layer passes into the slot between intake and fuselage, and only high-energy air enters the intake.

As airflow splits to flow around a moving vehicle, it must first accelerate because the presence of the vehicle forces the air to flow' farther than if it w'ent straight. This accelerating flowkeeps the boundary layer thin. But as the flow' moves around the vehicle’s shape, it must eventually decelerate again, and boundary layer growth is rapid here. Likewise, as observed by Bernoulli’s Principle, the high-speed regions of the flow have less pressure than the low-speed regions. The boundary layer, feeling the pressure rising ahead of it, slows even more, growing thicker all the time. Finally, it can stop and reverse direction. The boundary layer can become so thickened that it becomes unstable, causing the flow adjacent to it to detach from the vehicle’s surface. This flow separation is w'hy it is difficult to close the flow around a streamlined object. The separated region trails a large, turbulent w'ake, resulting in correspondingly large drag.

In the case of airplane wings, boundary-layer growth and flow separation are countered by special techniques. Sometimes high-energy air is blown into the boundary-layer growth regions through slots, sometimes by pumps. Sometimes the boundary layer is sucked away through arrays of holes. Most commonly, small tabs called “turbulators” are placed upstream from the trouble area. The local turbulence they cause blows the stagnant boundary layer away by entraining it into higher-energy flows.

In liquid-cooled engines, growth of boundary layers between moving coolant and hot engine surfaces acts as insulation, making it more difficult for the coolant to pick up heat. It is to prevent this that modern engines have thin waterjackets with coolant circulated very rapidly; this rapid motion causes turbulence that scours down the boundary layer, leading to more intimate contact between the metal and fresh coolant from within the stream.

The insulation value of the boundary layer works to our advantage inside engine combustion chambers. Stagnant gases are excellent insulators-this is the principle of double glazing in window insulation. Unfortunately, if knocking combustion occurs (detonation burning at the speed of sound, creating shock waves inside the cylinder), the insulating boundary layers on piston and head are torn away, allowing heat flow from combustion gas to the parts to increase. This is why detonation is usually accompanied by a rise in engine temperature.

As air flows through an intake port, into an engine cylinder during the intake stroke, a situation analogous to that of an airplane wing occurs. Flow along the top of the port is guided by it, but flow on the port bottom (called “the short side”) is just like airflowcurving down over the top of a wing. The boundary layer grows in thickness, then reverses direction, “tripping,” or causing the separation of the flow on the bottom of the port. The result is that intake flow occurs only near the top of the port, while at the bottom the separated flow may even reverse. The port cross-section looks generous, but don’t be deceived. Only the upper part of it is actually flowing high-speed air, so the effective crosssection is tiny. As a result, power development is disappointing. You can see the same basic phenomenon in large scale where a stream or river makes a sharp turn; the flow on the outside of the bend is vigorous, but on the inside, the flow has separated and is either swirling randomly, or actually flowing upstream.

The same can occur on the exhaust side. You bolt your cylinder head to the flowbench, set the exhaust valve opening to full lift, and blow air through the valve and out the port. As the air flows, it may make a roaring noise. This is the flow alternating rapidly between filling the whole port and separating from the floor, filling just the upper part of the port. If you slide your finger into the port on the bottom, the flow smooths out, the roaring ceases and the flow increases.

Something to think about the next time you're soaking in the tub. □

View Full Issue

View Full Issue