TDC

Less-than-extreme unction

THE CRANK AND CON-RODS IN MOST modern motorcycle engines are supported by plain, oil-lubricated journal bearings. On the crank, smooth, cylindrical journals are ground and finished, and each of these runs at a small clearance inside a pair of semi-circular metal shell bearings, with oil between. Most of the thickness of each shell is steel, with a minimum layer of soft bearing metals plated on the inner surfaces that face the crank journal.

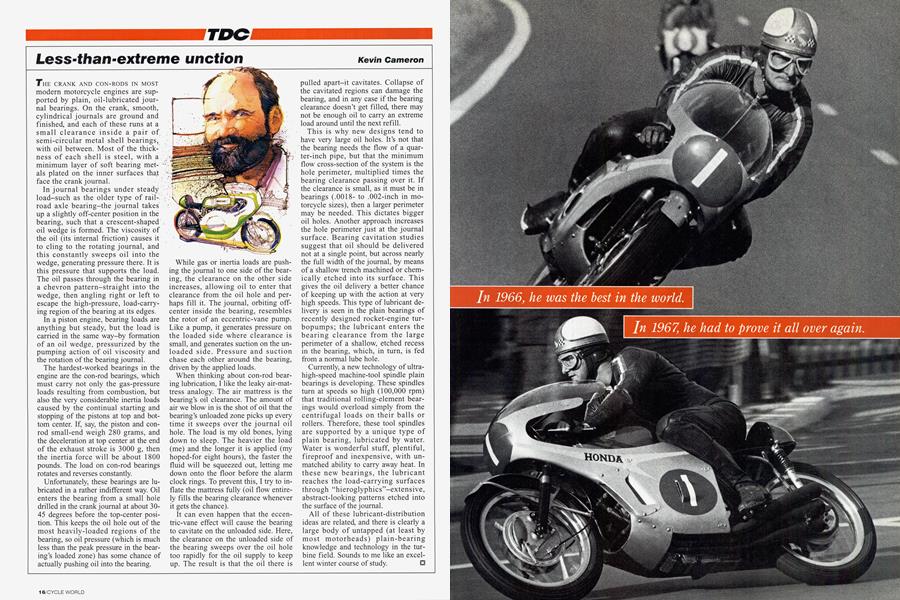

In journal bearings under steady load-such as the older type of railroad axle bearing-the journal takes up a slightly off-center position in the bearing, such that a crescent-shaped oil wedge is formed. The viscosity of the oil (its internal friction) causes it to cling to the rotating journal, and this constantly sweeps oil into the wedge, generating pressure there. It is this pressure that supports the load. The oil passes through the bearing in a chevron pattern-straight into the wedge, then angling right or left to escape the high-pressure, load-carrying region of the bearing at its edges.

In a piston engine, bearing loads are anything but steady, but the load is carried in the same way-by formation of an oil wedge, pressurized by the pumping action of oil viscosity and the rotation of the bearing journal.

The hardest-worked bearings in the engine are the con-rod bearings, which must carry not only the gas-pressure loads resulting from combustion, but also the very considerable inertia loads caused by the continual starting and stopping of the pistons at top and bottom center. If, say, the piston and conrod small-end weigh 280 grams, and the deceleration at top center at the end of the exhaust stroke is 3000 g, then the inertia force will be about 1800 pounds. The load on con-rod bearings rotates and reverses constantly.

Unfortunately, these bearings are lubricated in a rather indifferent way. Oil enters the bearing from a small hole drilled in the crank journal at about 3045 degrees before the top-center position. This keeps the oil hole out of the most heavily-loaded regions of the bearing, so oil pressure (which is much less than the peak pressure in the bearing’s loaded zone) has some chance of actually pushing oil into the bearing.

While gas or inertia loads are pushing the journal to one side of the bearing, the clearance on the other side increases, allowing oil to enter that clearance from the oil hole and perhaps fill it. The journal, orbiting offcenter inside the bearing, resembles the rotor of an eccentric-vane pump. Like a pump, it generates pressure on the loaded side where clearance is small, and generates suction on the unloaded side. Pressure and suction chase each other around the bearing, driven by the applied loads.

When thinking about con-rod bearing lubrication, I like the leaky air-mattress analogy. The air mattress is the bearing’s oil clearance. The amount of air we blow in is the shot of oil that the bearing’s unloaded zone picks up every time it sweeps over the journal oil hole. The load is my old bones, lying down to sleep. The heavier the load (me) and the longer it is applied (my hoped-for eight hours), the faster the fluid will be squeezed out, letting me down onto the floor before the alarm clock rings. To prevent this, I try to inflate the mattress fully (oil flow entirely fills the bearing clearance whenever it gets the chance).

It can even happen that the eccentric-vane effect will cause the bearing to cavitate on the unloaded side. Here, the clearance on the unloaded side of the bearing sweeps over the oil hole too rapidly for the oil supply to keep up. The result is that the oil there is

Kevin Cameron

pulled apart-it cavitates. Collapse of the cavitated regions can damage the bearing, and in any case if the bearing clearance doesn’t get filled, there may not be enough oil to carry an extreme load around until the next refill.

This is why new designs tend to have very large oil holes. It’s not that the bearing needs the flow of a quarter-inch pipe, but that the minimum flow cross-section of the system is the hole perimeter, multiplied times the bearing clearance passing over it. If the clearance is small, as it must be in bearings (.0018to .002-inch in motorcycle sizes), then a larger perimeter may be needed. This dictates bigger oil holes. Another approach increases the hole perimeter just at the journal surface. Bearing cavitation studies suggest that oil should be delivered not at a single point, but across nearly the full width of the journal, by means of a shallow trench machined or chemically etched into its surface. This gives the oil delivery a better chance of keeping up with the action at very high speeds. This type of lubricant delivery is seen in the plain bearings of recently designed rocket-engine turbopumps; the lubricant enters the bearing clearance from the large perimeter of a shallow, etched recess in the bearing, which, in turn, is fed from a normal lube hole.

Currently, a new technology of ultrahigh-speed machine-tool spindle plain bearings is developing. These spindles turn at speeds so high (100,000 rpm) that traditional rolling-element bearings would overload simply from the centrifugal loads on their balls or rollers. Therefore, these tool spindles are supported by a unique type of plain bearing, lubricated by water. Water is wonderful stuff, plentiful, fireproof and inexpensive, with unmatched ability to carry away heat. In these new bearings, the lubricant reaches the load-carrying surfaces through “hieroglyphics”-extensive, abstract-looking patterns etched into the surface of the journal.

All of these lubricant-distribution ideas are related, and there is clearly a large body of untapped (at least by most motorheads) plain-bearing knowledge and technology in the turbine field. Sounds to me like an excellent winter course of study. □

View Full Issue

View Full Issue