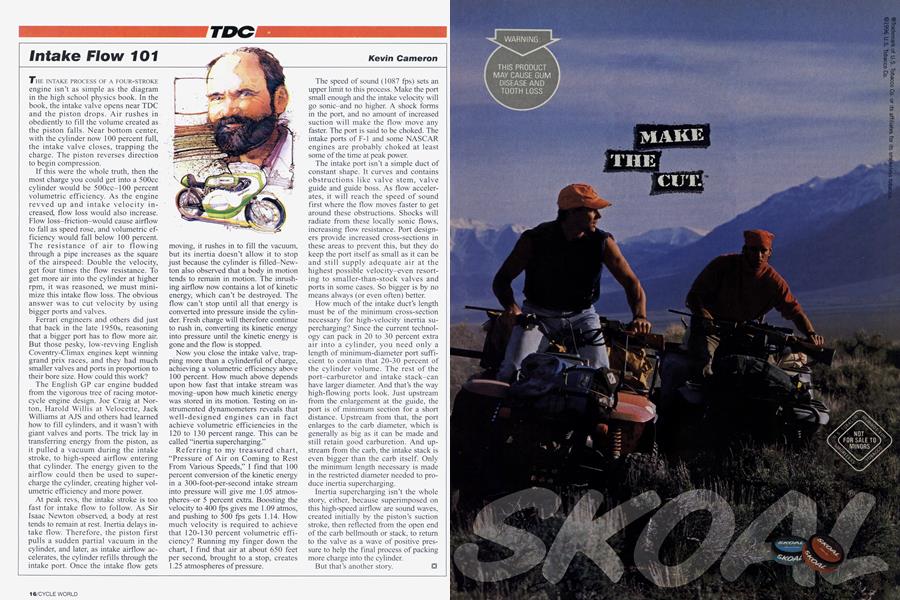

Intake Flow 101

TDC

Kevin Cameron

THE INTAKE PROCESS OF A FOUR-STROKE engine isn’t as simple as the diagram in the high school physics book. In the book, the intake valve opens near TDC and the piston drops. Air rushes in obediently to fill the volume created as the piston falls. Near bottom center, with the cylinder now 100 percent full, the intake valve closes, trapping the charge. The piston reverses direction to begin compression.

If this were the whole truth, then the most charge you could get into a 500cc cylinder would be 500cc-l00 percent volumetric efficiency. As the engine revved up and intake velocity increased, flow loss would also increase. Flow loss-friction-would cause airflow to fall as speed rose, and volumetric efficiency would fall below 100 percent. The resistance of air to flowing through a pipe increases as the square of the airspeed: Double the velocity, get four times the flow resistance. To get more air into the cylinder at higher rpm, it was reasoned, we must minimize this intake flow loss. The obvious answer was to cut velocity by using bigger ports and valves.

Ferrari engineers and others did just that back in the late 1950s, reasoning that a bigger port has to flow more air. But those pesky, low-revving English Coventry-Climax engines kept winning grand prix races, and they had much smaller valves and ports in proportion to their bore size. How could this work?

The English GP car engine budded from the vigorous tree of racing motorcycle engine design. Joe Craig at Norton, Harold Willis at Velocette, Jack Williams at AJS and others had learned how to fill cylinders, and it wasn’t with giant valves and ports. The trick lay in transferring energy from the piston, as it pulled a vacuum during the intake stroke, to high-speed airflow entering that cylinder. The energy given to the airflow could then be used to supercharge the cylinder, creating higher volumetric efficiency and more power.

At peak revs, the intake stroke is too fast for intake flow to follow. As Sir Isaac Newton observed, a body at rest tends to remain at rest. Inertia delays intake flow. Therefore, the piston first pulls a sudden partial vacuum in the cylinder, and later, as intake airflow accelerates, the cylinder refills through the intake port. Once the intake flow gets

moving, it rushes in to fill the vacuum, but its inertia doesn’t allow it to stop just because the cylinder is filled-Newton also observed that a body in motion tends to remain in motion. The inrushing airflow now contains a lot of kinetic energy, which can’t be destroyed. The flow can’t stop until all that energy is converted into pressure inside the cylinder. Fresh charge will therefore continue to rush in, converting its kinetic energy into pressure until the kinetic energy is gone and the flow is stopped.

Now you close the intake valve, trapping more than a cylinderful of charge, achieving a volumetric efficiency above 100 percent. How much above depends upon how fast that intake stream was moving-upon how much kinetic energy was stored in its motion. Testing on instrumented dynamometers reveals that well-designed engines can in fact achieve volumetric efficiencies in the 120 to 130 percent range. This can be called “inertia supercharging.”

Referring to my treasured chart, “Pressure of Air on Coming to Rest From Various Speeds,” I find that 100 percent conversion of the kinetic energy in a 300-foot-per-second intake stream into pressure will give me 1.05 atmospheres-or 5 percent extra. Boosting the velocity to 400 fps gives me 1.09 atmos, and pushing to 500 ips gets 1.14. How much velocity is required to achieve that 120-130 percent volumetric efficiency? Running my finger down the chart, I find that air at about 650 feet per second, brought to a stop, creates 1.25 atmospheres of pressure. The speed of sound (1087 fps) sets an upper limit to this process. Make the port small enough and the intake velocity will go sonic-and no higher. A shock forms in the port, and no amount of increased suction will make the flow move any faster. The port is said to be choked. The intake ports of F-l and some NASCAR engines are probably choked at least some of the time at peak power.

The intake port isn’t a simple duct of constant shape. It curves and contains obstructions like valve stem, valve guide and guide boss. As flow accelerates, it will reach the speed of sound first where the flow moves faster to get around these obstructions. Shocks will radiate from these locally sonic flows, increasing flow resistance. Port designers provide increased cross-sections in these areas to prevent this, but they do keep the port itself as small as it can be and still supply adequate air at the highest possible velocity-even resorting to smaller-than-stock valves and ports in some cases. So bigger is by no means always (or even often) better.

How much of the intake duct’s length must be of the minimum cross-section necessary for high-velocity inertia supercharging? Since the current technology can pack in 20 to 30 percent extra air into a cylinder, you need only a length of minimum-diameter port sufficient to contain that 20-30 percent of the cylinder volume. The rest of the port-carburetor and intake stack-can have larger diameter. And that’s the way high-flowing ports look. Just upstream from the enlargement at the guide, the port is of minimum section for a short distance. Upstream from that, the port enlarges to the carb diameter, which is generally as big as it can be made and still retain good carburetion. And upstream from the carb, the intake stack is even bigger than the carb itself. Only the minimum length necessary is made in the restricted diameter needed to produce inertia supercharging.

Inertia supercharging isn’t the whole story, either, because superimposed on this high-speed airflow are sound waves, created initially by the piston’s suction stroke, then reflected from the open end of the carb bellmouth or stack, to return to the valve as a wave of positive pressure to help the final process of packing more charge into the cylinder.

But that’s another story.