CW SPECIALITY FILE

HIGH-TECH AND HANDSOME

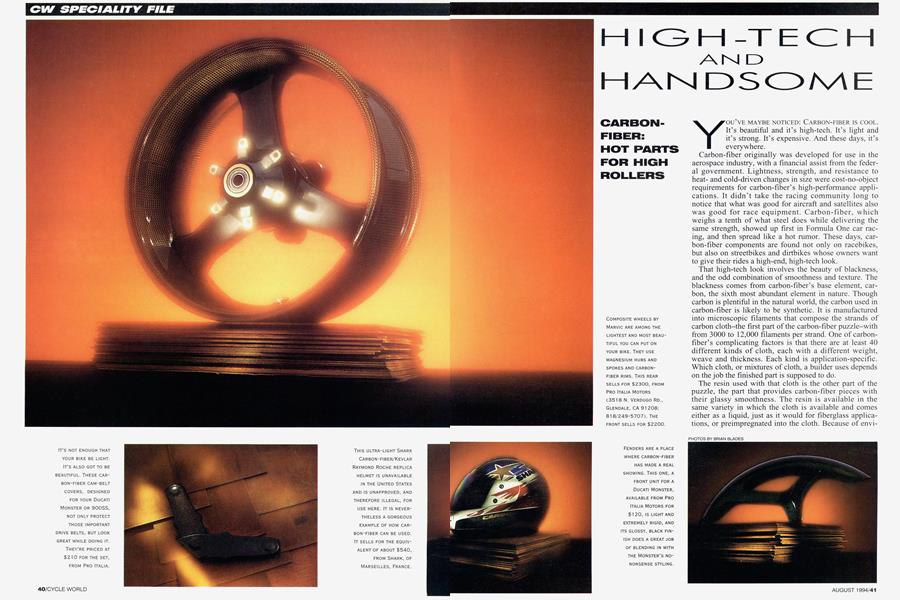

CARBONFIBER: HOT PARTS FOR HIGH ROLLERS

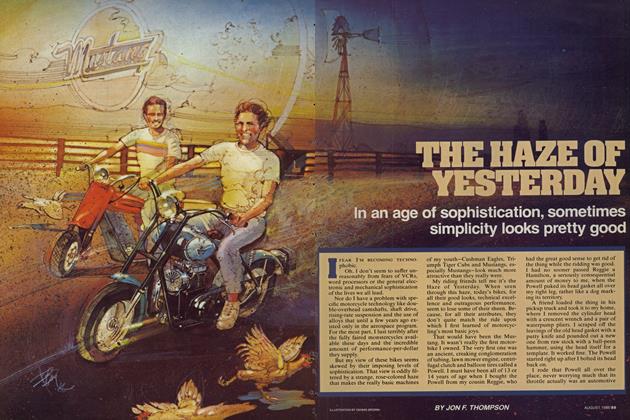

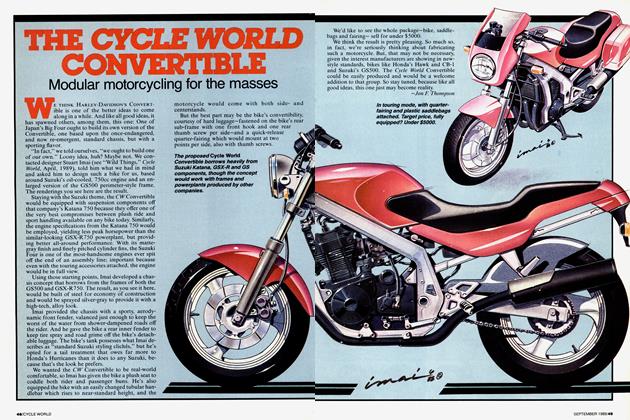

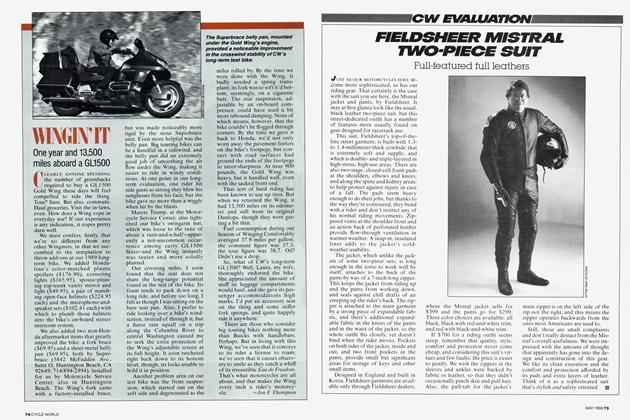

YOU'VE MAYBE NOTICED: CARBON-FIBER IS COOL. It's beautiful and it's high-tech. It's light and it's strong. It's expensive. And these days, it's everywhere. Carbon-fiber originally was developed for use in the aerospace industry, with a financial assist from the federal government. Lightness, strength, and resistance to heatand cold-driven changes in size were cost-no-object requirements for carbon-fiber’s high-performance applications. It didn’t take the racing community long to notice that what was good for aircraft and satellites also was good for race equipment. Carbon-fiber, which weighs a tenth of what steel does while delivering the same strength, showed up first in Formula One car racing, and then spread like a hot rumor. These days, carbon-fiber components are found not only on racebikes, but also on streetbikes and dirtbikes whose owners want to give their rides a high-end, high-tech look.

That high-tech look involves the beauty of blackness, and the odd combination of smoothness and texture. The blackness comes from carbon-fiber’s base element, carbon, the sixth most abundant element in nature. Though carbon is plentiful in the natural world, the carbon used in carbon-fiber is likely to be synthetic. It is manufactured into microscopic filaments that compose the strands of carbon cloth-the first part of the carbon-fiber puzzle-with from 3000 to 12,000 filaments per strand. One of carbonfiber’s complicating factors is that there are at least 40 different kinds of cloth, each with a different weight, weave and thickness. Each kind is application-specific. Which cloth, or mixtures of cloth, a builder uses depends on the job the finished part is supposed to do.

The resin used with that cloth is the other part of the puzzle, the part that provides carbon-fiber pieces with their glassy smoothness. The resin is available in the same variety in which the cloth is available and comes either as a liquid, just as it would for fiberglass applications, or preimpregnated into the cloth. Because of envi-

ronmental concerns associated with liquid resins, this latter option increasingly is the choice of carbon-fiber manufacturers.

However carbon-fiber’s two components finally meet, they’re layered into the precision mold that will give the finished part its form. The mold is a specialized requirement because, unlike wet-laminate fiberglass, carbon cloth won’t absorb resin without pressure or vacuum. So the mold must be built to apply one of those qualities while the part is being oven-baked at temperatures ranging from 150 to 375 degrees, for times ranging from 15 minutes to 6 hours, depending upon the complexity of the part and the type of resin used. Even the oven used for this baking is special. It must be equipped to bake while supplying the vacuum required to pull mold-halves together, impregnating the cloth with the resin and purging any trapped air and excess resin. When the part is baked, it’s removed from the oven, partially cooled, finish trimmed, cooled some more, then removed from its mold, gleaming and beautiful.

Expensive, too, for a variety of reasons. The cloth costs up to $30 per yard and is not sold in small lots. The resin is equally costly. Building the molds used to make the parts is time-consuming work done by specialists. No manufacturer who plans to make money on his product builds one of anything-he has to tool up for production, and that further expands his costs because he needs several ovens, and several molds for each part he produces.

So you pay heavy money to get light, strong parts-parts like those shown here. They come from a variety of sources and are intended for a variety of applications, but they all have these things in common: They’re light, and beautiful, and a growing community of riders is learning that they look great on motorcycles.

Jon F. Thompson

A tip of the Cycle World helmet to Bill West and Charles Coffey, of MMF-Fiberworks, for a short-course in the design and production of carbon-fiber parts.

View Full Issue

View Full Issue

More From This Issue

-

Columns

ColumnsUp Front

August 1994 By David Edwards -

Columns

ColumnsLeanings

August 1994 By Peter Egan -

Columns

ColumnsTdc

August 1994 By Kevin Cameron -

Letters

LettersLetters

August 1994 -

Roundup

RoundupMorbidelli's 24-Carat Motorcycle

August 1994 By Jon F. Thompson -

Roundup

RoundupWestinghouse Puts A Charge Into Riding

August 1994 By Brenda Buttner