The Big Squeeze

CW SPECIALITY FILE

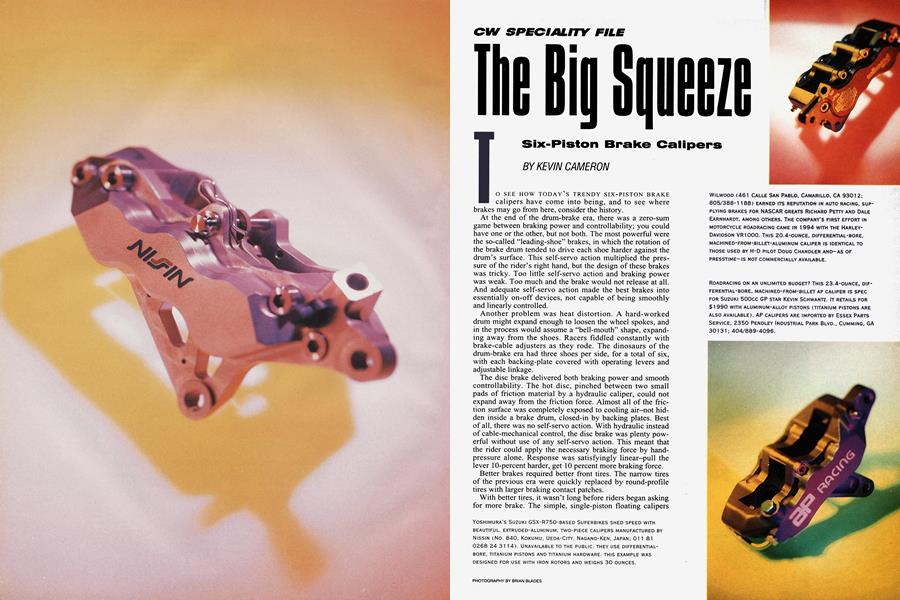

Six-Piston Brake Calipers

KEVIN CAMERON

TO SEE HOW TODAY’S TRENDY SIX-PISTON BRAKE calipers have come into being, and to see where brakes may go from here, consider the history.

At the end of the drum-brake era, there was a zero-sum game between braking power and controllability; you could have one or the other, but not both. The most powerful were the so-called “leading-shoe” brakes, in which the rotation of the brake drum tended to drive each shoe harder against the drum’s surface. This self-servo action multiplied the pressure of the rider’s right hand, but the design of these brakes was tricky. Too little self-servo action and braking power was weak. Too much and the brake would not release at all. And adequate self-servo action made the best brakes into essentially on-off devices, not capable of being smoothly and linearly controlled.

Another problem was heat distortion. A hard-worked drum might expand enough to loosen the wheel spokes, and in the process would assume a “bell-mouth” shape, expanding away from the shoes. Racers fiddled constantly with brake-cable adjusters as they rode. The dinosaurs of the drum-brake era had three shoes per side, for a total of six, with each backing-plate covered with operating levers and adjustable linkage.

The disc brake delivered both braking power and smooth controllability. The hot disc, pinched between two small pads of friction material by a hydraulic caliper, could not expand away from the friction force. Almost all of the friction surface was completely exposed to cooling air-not hidden inside a brake drum, closed-in by backing plates. Best of all, there was no self-servo action. With hydraulic instead of cable-mechanical control, the disc brake was plenty powerful without use of any self-servo action. This meant that the rider could apply the necessary braking force by handpressure alone. Response was satisfyingly linear-pull the lever 10-percent harder, get 10 percent more braking force.

Better brakes required better front tires. The narrow tires of the previous era were quickly replaced by round-profile tires with larger braking contact patches.

With better tires, it wasn’t long before riders began asking for more brake. The simple, single-piston floating calipers of Honda and Kawasaki were left behind by the hefty, castiron calipers on the first TZ750 Yamahas in 1974. These twin-piston units carried big 50mm-diameter pads, pushed by a pair of opposed 48mm pistons.

It took a little while for riders to exploit the gains, but tires improved and the complaints started anew: More brakes! Now there was a fresh problem: disc coning. As the round 50mm pad gripped a 300mm disc, there was a big difference in diameter between the outside diameter (OD) and the inside diameter (ID) of the pad’s friction track on the disc; 300mm vs. 200mm. This translated to a big velocity difference between ID and OD, which created a much higher disc-heating rate at the OD than at the ID. During braking, the very hot disc OD expanded, stretching the inner parts of the disc outward. When the disc cooled, the outer region contracted, but the inner part was permanently a bit bigger than before. The only way this is possible is for the disc to assume a slight cone shape. And the more the disc coned in this way, the more crooked it ran through the jaws of the caliper. Disc coning thus pushed the caliper pistons back farther than usual. When the rider went for the lever at the next turn, it might come to the bar and require a panicky second pull to make it bite.

The first fix was to build floating mounts for discs, that would permit the disc to expand without having to pull the carrier with it. A cheaper, ad hoc fix was to cut radial slots in the disc (Yamaha did this on its TZ500 in 1980) to make it lie flat again.

But as riders braked ever-harder, even discs on floating mounts began to cone from differential heating-or crack from the stresses involved. The answer was to find a way to narrow the pad track on the disc, so as to make OD and ID heating rates more equal. This meant changing the shape of the pad, making it longer around the disc, and narrower in the radial direction. And the only way to accomplish this without having the pad outgrow the piston was to operate each longer, narrower pad with two smaller pistons. The resulting four-piston calipers thus used a longer, narrower pad that did not result in widely different heating rates between OD and ID.

A welcome side benefit of the four-piston design was increased rigidity. Because it did not “bite” so deeply on the disc, there was less leverage tending to pry the caliper open. Therefore, the caliper flexed less, so more of the rider’s hand stroke went into applying useful pressure on the pads, and less was wasted in just flexing the caliper(s).

Perversely and inevitably, the tire makers continued their build-up of front traction, causing riders to again brake harder. To deliver more hydraulic pressure to the pistons, brake engineers boosted the leverage by using smaller master-cylinder pistons (same hand pressure against a smaller piston equals higher psi output). This, in turn, brought back the problem of caliper flex, which again wasted more brake-lever movement. Riders were once more heard to complain, “It comes to the bar!” For a time, riders had to choose between high braking power with an uncertain, mushy lever feel (small master cylinder piston and high line pressure), and lower braking power but with a rock-solid lever (larger master cylinder piston, lower line pressure). It was a no-win situation.

The response has been predictable; to narrow the caliper’s bite on the disc again and again improve caliper rigidity and lever feel by going from four pistons to six. This permits use of longer, narrower pads (or individual pads, one per piston).

And where does it all lead? Aircraft brakes have already trodden this path. They now resemble multi-plate clutches, with the pressure applied by a complete ring of pistons. As the disc is progressively covered up by longer and longer calipers, cooling eventually becomes the problem. After a single maximum-G stop, aircraft brakes must cool for half an hour.

Calipers are aluminum because it is light, but aluminum has only one-third the rigidity of iron. Back when Yamaha offered both iron and aluminum calipers in the same design, the top riders all used the iron calipers because they flexed less (lever did not come to the bar). Today, no one would suggest putting iron calipers on sport or racing motorcycles; too heavy. One approach is not to cast the caliper, but to machine it from wrought stock. The wrought material has somewhat better properties than the cast, so it can be lighter for a given rigidity, or more rigid for a given weight. These CNC-machined billet calipers are beautiful, but that beauty is expensive. Beyond that are AP’s latest auto-racing calipers, made from a high rigidity metal matrix composite (MMC). AP’s MMC material is aluminum filled with ceramic fibers.

Another way to combine a solid lever with high force at the pad is the use of power braking, now common in powerful racing cars. Instead of using a very small master-cylinder piston to boost brake-line pressure (leading to the problem of excessive lever stroke), a power brake employs external power to multiply the force applied by the rider. If tire traction and brake durability continue along the course they have followed for these many years, we will arrive at power brakes soon.

The heat of competition has created the multi-piston caliper, but on the street, these calipers are more of a vanity than a necessity. Sportbikes wear them in increasing numbers because that’s what it takes to win in production racing, and that racy look is what it takes to sell product.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontDoin' the Wave

June 1995 By David Edwards -

Leanings

LeaningsDucks Unlimited

June 1995 By Peter Egan -

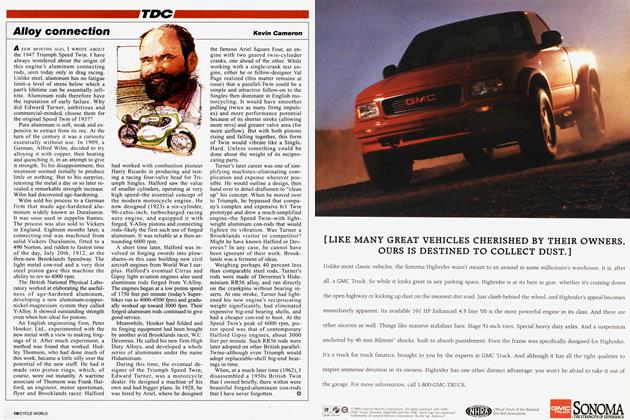

TDC

TDCAlloy Connection

June 1995 By Kevin Cameron -

Letters

LettersLetters

June 1995 -

Roundup

RoundupBandits Coming Soon To Your Neighborhood

June 1995 By Robert Hough -

Roundup

RoundupYamaha's Surprise Single

June 1995 By Robert Hough