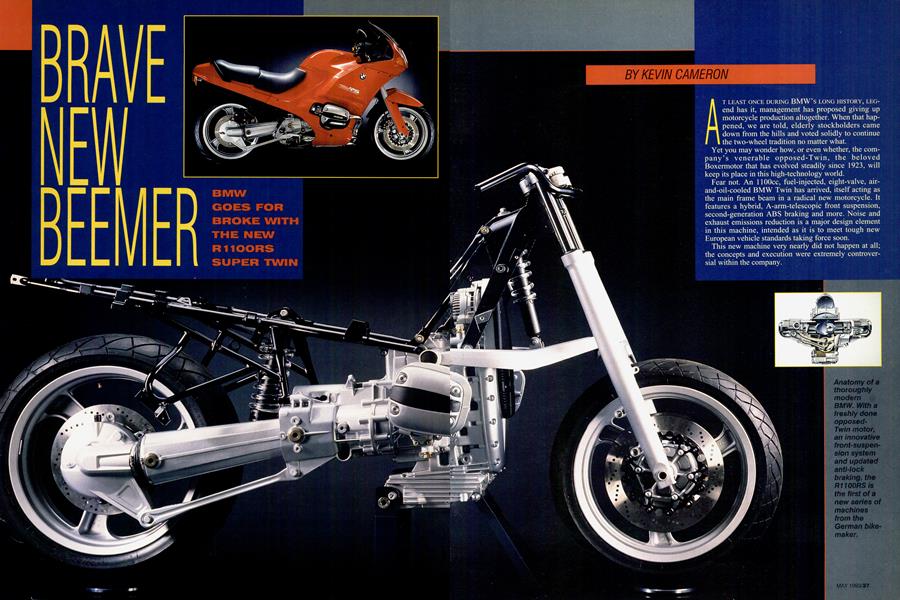

BRAVE NEW BEEMER

BMW GOES FOR BROKE WITH THE NEW R1100RS SUPER TWIN

KEVIN CAMERON

AT LEAST ONCE DURING BMW’S LONG HISTORY, LEGend has it, management has proposed giving up motorcycle production altogether. When that happened, we are told, elderly stockholders came down from the hills and voted solidly to continue the two-wheel tradition no matter what.

Yet you may wonder how, or even whether, the company’s venerable opposed-Twin, the beloved Boxermotor that has evolved steadily since 1923, will keep its place in this high-technology world.

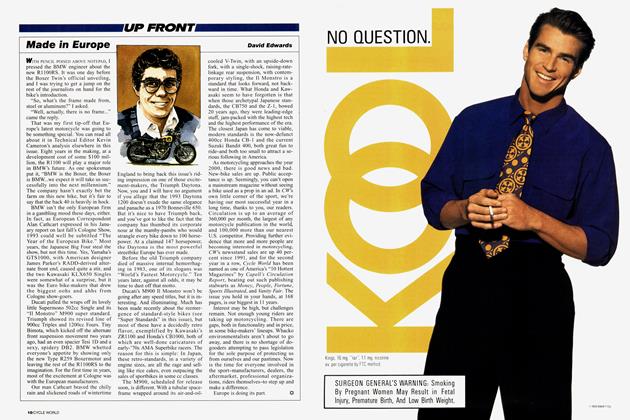

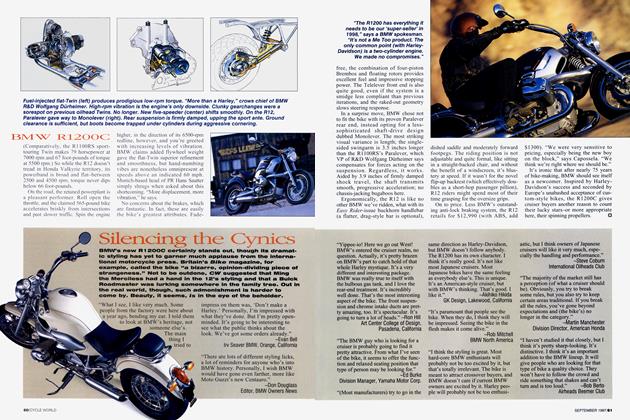

Fear not. An 1100cc, fuel-injected, eight-valve, airand-oil-cooled BMW Twin has arrived, itself acting as the main frame beam in a radical new motorcycle. It features a hybrid, A-arm-telescopic front suspension, second-generation ABS braking and more. Noise and exhaust emissions reduction is a major design element in this machine, intended as it is to meet tough new European vehicle standards taking force soon.

This new machine very nearly did not happen at all; the concepts and execution were extremely controversial within the company.

BMW’s first products, back in 1916, were aircraft. It then shifted to production of sophisticated liquidcooled, overhead-cam aircraft engines (the BMW Ilia set an altitude record of over 30,000 feet in 1919). This was the genesis of the famous blue-and-white BMW circle emblem; the logo symbolizes a spinning propeller in sunlight. The World War I peace settlement limited Germany’s aircraft production, so BMW had to seek other markets. The outcome was Max Friz’s classic 1923 engine design.

Twenty-five years later, BMW’s post-WWII motorcycles established a reputation for conservative solidity. That was a survival strategy; motorcycle popularity in Europe peaked in 1955, then almost died out as mass-produced autos grabbed the market. Nevertheless, engineering is a strong tradition in the company: BMW was first with a production telehydraulic fork in 1935, and won the 500cc world title with a roadracing flat-Twin in 1938. The reputation of the auto division is strong on both road and track.

In 1984, shortly after the K series of laydown-Fours was finished, BMW engineers were given the task of updating the Boxer Twin. They faced two kinds of problems: One was to meet foreseeable social standards (noise, emissions, durability, recyclability), the other was to raise the Twin’s competence in all aspects (handling, braking, stability, power) to meet or exceed the constantly rising expectations of buyers worldwide.

The new machine keeps little from the recent past, save for the special sound and feel of a flat-Twin, and the proven Paralever single-sided swingarm. There is no chassis as such, for the engine is the major structure. The telescopic fork is gone, replaced by an innovative design that resolves braking and suspension loads through a large, forward-projecting A-arm that pivots on the engine cases. This removes most of the cause of fork stiction, resulting in an unusually supple and strong suspension that is still directly steered. And although BMW has produced 40,000 motorcycles with the first-generation FAG-Kugelfischer anti-lock brake system, that is now replaced by the even more capable ABS II.

THE MAKING OF THE R1100RS

The best way to produce an engine that is both powerful and easy to ride is to make it bigger. The traditional hop-up methods-more compression, longer cams, bigger ports-all have drawbacks. BMW’s new Type 259 engine is therefore 1085cc, with 99 x 70.5mm bore and stroke yielding a decidedly modem bore/stroke ratio of 1.4. Peak claimed output of 90 horsepower is given at 7250 rpm, for a leisurely piston speed of under 3500 feet per minute. Cylinder filling is good, with BMEP (the strokeaveraged combustion pressure) peaking at 158 psi at the 5500-rpm torque peak. The 10.7:1 compression ratio is high for so large a bore, requiring premium fuel.

Engineers expect more vibration from a bigger engine, but an opposed-Twin is naturally in primary and secondary balance. Natural balance doesn’t mean there are no large forces inside the engine; it means only that they cancel. The heavier the vibratory loads from piston and rod motion, the more heavily built the cases must be to contain them.

BMW borrowed from its first-hand knowledge of Formula One auto racing to give its new Twin very light pistons. These are little more than disembodied domes, carrying rings, each with a pair of posts to accept a very short wristpin. Minimal skirts are provided to stabilize the piston in the bore.

Because the cylinders must be offset to allow the connecting rods to pass each other, there is a small rocking couple-the engine oscillates around a vertical axis through the engine’s center of mass. The need to minimize this rocking motion dictated use of a two-bearing crankshaft; a third bearing, between the con-rods, would accentuate this motion. The Rl 100’s con-rods are made nearly to net shape by powder metallurgy. Long used in the high-volume automotive world, so-called “powder parts” are sintered from metal powder of precise composition, then hot forged into complete solidity. Dimensional accuracy is excellent and little post-machining is needed. The new Twin’s cam lobes are likewise powder parts. Each connecting rod is forged as one piece, then the big-end caps are created by intentional fracturing. The irregular fracture surfaces form a joint that is self-locating (no dowels or tabs needed to align the halves) and eliminates an expensive precision machining process.

The best combination of power with ridability is provided through use of four valves per cylinder, which can flow plenty of air without needing the long cam timings that make engines peaky. Use of four-valve heads in the Boxer Twin presented special problems, however. The Boxer design was originally created to provide excellent air-cooling (German aircraft engines of WWI were noted for their well-thought-out cooling arrangements), but it’s hard to cool a modem four-valve head with air.

Why? To provide a compact combustion chamber without an intrusively tall piston dome, the angle between intake and exhaust valves must be small. But this makes it hard to get cooling air into the critical region between the valves. Also, the more holes you cut into a cylinder head, the weaker it becomes, inviting distortion or cracking. The region between exhaust-valve seats is especially tricky. BMW decided to supplement air cooling with considerable internal oil circulation-including a passage to cool the exhaust seats. To prevent oil in that region from coking after engine shutdown (when circulation would stop, and heat soak-back would overheat the region), a standpipe was created to hold enough oil in the hot region to handle the heat without reaching coking temperature.

For sporting performance, a motorcycle must be capable of large angles of lean; but pile too much machinery on the Boxer’s projecting heads and you have a grounding problem. To meet noise standards, the former Twin’s long pushrods had to go, yet the new valve drive would have to be capable of the short, abrupt action that four valves require. That, in turn, called for the lightest possible valvetrain.

The obvious answer-overhead cams-was out; they would be “under the tar” in fast turns. Whatever the choice of machinery, it would have to fit into the confining wedge formed between right and left angles of lean.

BMW’s solution is similar in concept to that on Moto Guzzi’s new four-valve 1000 Daytona. A half-time shaft beneath the engine is chain-driven from the crank. Chains from it drive a camshaft located under each head. Bucket tappets and stub pushrods actuate a pair of vertically disposed, forked rockers to operate the paired 36mm intake and 31mm exhaust valves. Chain noise is suppressed by mbber-faced tensioner/dampers.

Emissions reduction dictated the use of fuel injection; the R1100’s automotive-style three-way exhaust catalyst system (standard in the U.S., optional in most of Europe) requires accurate feedback control of fuel mixture. An oxygen sensor in the pipe, working with the fuel-control computer, keeps the fuel/air mixture cycling narrowly between rich and lean, guaranteeing that the catalyst receives only exhaust from near-stoichiometric (fancy, mouth-filling word for chemically correct) combustion. In this narrow mixture range, carbon monoxide, unburned hydrocarbons and oxides of nitrogen can all be converted to plain old carbon dioxide, water and nitrogen with fair efficiency.

This new engine couples to a five-speed gearbox through BMW’s familiar direct-coupled flywheel/single-disc clutch.

And now for the radical chassis and suspension. Innovation is all very well, but new features have new costs. Clearly, a new kind of chassis would be needed for the new Twin, one with stiffness adequate to exploit the powerful grip of modem tires. The twinloop, steel tube chassis is receding into the past. A multi-tube chassis like Ducati’s has attractions, but its bulk and many joints are problems. What about an aluminumbeam chassis? New equipment for forming and welding aluminum would have to be bought for the production line, and many problems of corrosion and fatigue resistance would have to be addressed. Costs would be heavy.

Why not just do away with the chassis, as with the classic Vincent motorcycle, or more recently, in the John Britten V-Twin? An engine as stiff as the new Type 259 would be an excellent basis for a chassis. Existing factory methods could easily produce the supplementary steel-tube subframes such a design would need.

At the rear, the proven Paralever system would be the obvious suspension choice, being rugged and almost free from torque reaction. Why not just use a well-executed telescopic fork at the front? The problems with conventional telescopic forks are these: All braking and turning loads are reacted through the closely spaced fork tube/slider bearings, which bind under these loads; hard braking makes teleforks essentially rigid; tele-forks are pro-dive and the rake of their tubes subjects them to extra compression during braking, requiring either longer travel or stiffer springs. Further, tele-forks transmit loads from the tire upward 30 inches or so to a steering head that must be heavily built to handle the leverage, and the chassis must then carry these loads back down to axle level to connect to the rear swingarm. Why pay for a rambling load path with unnecessary flex and weight? If the aim of a new chassis was increased rigidity without weight penalty, why not integrate a new front suspension into that concept?

New front-end concepts are plentiful, but many, like the Bimota Tesi’s hub-center device, involve steering through linkage of some kind. Riders have generally rejected their lack of feel. This made direct steering a preference for BMW’s project. Some alternative suspensions and the extremely rigid, big-tube telescopies used on current GP bikes suffer from kick-back-having essentially no flex, they pass along everything to the rider as sudden torques at the bars. Non-racers naturally reject this discomfort.

Another problem is appearance. To many viewers, “Buck Rogers” high-tech suspensions just look weird. BMW therefore was less attracted to solutions like the Yamaha/RADD, with visible, massive beams placed at axle level.

The front suspension developed by BMW as the Telelever originated in England as the Nicol Link. It combines major elements of a telescopic fork with the rigidity and short load path of a forward-projecting A-arm, based solidly on the engine crankcase.

Here is how it works. The two fork sliders are joined by a bridge just above the tire, and at this point, a ball-joint connects to the apex of the A-arm. The A-arm’s motion is controlled by a single spring/damper unit. Thus, braking, turning and suspension loads travel a greatly shortened (and strengthened) load path through this link. The fork sliders do not end at the bridge, but continue on upward. Their great length (nearly twice that of conventional fork sliders) provides wider separation between slider bearings on the pair of inner tubes, thus cutting stiction. The two inner tubes are joined by a second bridge at their tops. Here, a second ball-joint attaches to a pyramidal structure, built upward from the front of the engine. The rider’s bars connect directly here without linkage.

What lateral flexibility there is in the telescopic part of this suspension deals with the kick-back problem. Telelever is not pro-dive because brake forces react to the A-arm. Because riders prefer some dive as a means of gauging braking effort, a degree of dive is designed into BMW’s new front end. As a partial result, a modest travel of only 4.7 inches is needed at the front. Telelever also satisfied appearance criteria: It looks like a telescopic, with the Aarm almost invisible below the forward part of the fairing.

At the rear, the single-sided Parale ver swingarm projects aft from the gearbox section, with its suspension load carried by a single, centrally placed spring/damper unit working without a linkage. Travel of the 18-inch rear wheel is 5.3 inches.

More capability in engine and chassis requires appropriate braking power. The RS has Brembo four-piston calipers with twin 12.2-inch discs at the front, a single 11.4-inch disc and twin-piston caliper at the rear, as on the K100. The new FAG-Kugelflscher ABS II anti-lock system will be offered as an option, though U.S. BMW officials indicate that ABS is so popular with its customers that 85 percent of R1100RS models imported will be already equipped with the system.

Anti-lock brake systems sense the beginnings of wheel lock-up, then take action to (a) isolate the brake system from the rider’s master cylinder and (b) reduce brake torque enough to keep the wheel turning and under control, then (c) return control to the rider’s master cylinder. The system does all of this in a rapidly repeating cycle, many times per second.

BMW’s first ABS used toothed rings, attached to the wheels, with sensors to measure their speed. Multiple selfchecking computers detected imminent lock-up, then ordered a hefty solenoid to first seal off the rider’s master cylinder, then pull a small amount of fluid from the brake line. This dropped the pressure, allowing the wheel to regain speed, after which the solenoid restored line pressure and returned control to the rider in a cycle repeated as long as lock-up continued to threaten. The speed of this cycle was limited somewhat by the considerable mass of the solenoid’s armature. Subsequently developed ABS systems from other makers have offered higher cycling speeds and, at least potentially, superior performance.

The ABS II on the new Boxer employs the toothed rings, sensors and multiple computers, together with a novel drive system. A small motor spins, and on its shaft is an electromagnetic clutch, coupled to a valve and piston much like those used in ABS I. When ABS action is ordered by the computers, a small current activates the electro-clutch, causing the motor torque to pull back the valve and piston, isolating the rider’s master cylinder and pulling fluid from the line in the familiar way. Cyclic speed is increased by the low mass of the moving parts. Because only a small current is required to operate the device, electrical requirements are reduced. With the heavy linear motors eliminated, weight is likewise cut.

An interesting note is that ABS and the new front suspension complement each other. All front ends of whatever stiffness have a characteristic natural frequency of forwards-and-back vibration (older riders will remember the flutter of an idling Triumph twin’s front wheel). The stiffer the structure, the higher the frequency. The cyclic action of ABS can excite this vibration disturbingly, so the high front-to-back stiffness of the Telelever suspension is an ideal platform for a high-cyclic-speed ABS.

otorcycling is not an entirely rational undertaking. Motorcycles want to fall over when they stop, and they leak profusely in rainstorms. Cars solve both these problems, yet motorcyclists persist in their idiosyncratic choice of vehicle. Obviously, functionality is not the whole story in motorcycle choice. Do you choose friends based on their ability to run the 100 in 9.6? There are other, perhaps unanalyzable, factors in the choosing-of friends or of motorcycles. In the new Boxer R1100RS, BMW has combined elements of well-proven appeal to motorcyclists-the 1923 concept of a smooth opposed-Twin driving through a shaft-with contemporary engineering to produce a capable, modem motorcycle with strong personality. Congratulations are in order.

View Full Issue

View Full Issue