Pumped

TDC

Kevin Cameron

THINGS ARE HAPPENING DOWN IN THE crankcase as you cruise merrily along, and not all of them are good.

On partial throttle, there is very little pressure in the cylinder on the intake stroke, but there is essentially at mospheric pressure in the crankcase. It therefore takes work to overcome this pressure difference as the piston moves. This is called pumping loss.

In single-cylinder tour-stroke en gines-especially in older designs with full-circle flywheels and close fitting cases-the fall of the piston pumps the case up to much higher than atmospheric pressure, exagger ating the pumping loss, and leading to other problems with oil control, seal popping, etc. A similar situation exists with big parallel-Twins (Tn um~h, BSA, Norton) and flat-Twins (BMW Boxer). These are therefore usually equipped with timed crank case breathers, so that case air is ex pelled on the downstroke, but cannot return on the upstroke.

Another effective measure against excess case pressure is to increase case volume, thereby softening the air "spring" under the pistons. This may take the form of a big under engine sump, or of a large port from crankcase to chaincase or gearbox. Both are often seen on racing Harley Davidson engines.

Certain drag-racing auto engines pump their crankcases down by sim ply connecting them to the intake manifold (after taking suitable mea sures to prevent case seals from turn ing inside-out). This pulls the case down initially, and high-rpm pump ing is taken care of by running a vac uum line, with a one-way valve in it, to the center of the exhaust header collector. There is reputedly a small power gain, especially when this technique permits oil-control rings to be eliminated from the pistons.

Poor piston-ring sealing increases blowby, which pressurizes the crank case even further-possibly enough to overcome the normal remedies. Experienced Moto Guzzi tuner John Wittner notes that some designs with low piston rigidity, and with very heavy or extremely short con-rods, produce a lot of piston deformation at high rpm, leading to blowby even when the rings are fine.

Losses in the crankcase can occur in other ways, as well. You'd expect a four-cylinder design to have a nearconstant case pressure because two pistons rise while the other pair fall. But the air has to get from one cylin der bottom to the next. In some de signs, the air must follow a tortuous path through small holes, possibly through the gearbox, to do this. As much as several horsepower are lost in the process. Recent designs incor porate large, smooth-edged holes in the main-bearing webs to equalize pressures in the crankcase.

More power is notoriously lost by transfer of momentum from moving parts to oil. Stirring and whacking oil around in the crankcase slows the crank and rods, and this lost power translates to a higher oil temperature. This can also result in wet-sumping, in which the volume of the scavenge pump. whose job it is to return crank case oil to an external tank, is over whelmed by the increased bulk of foamed oil. Harley-Davidson's for mer racing manager, Dick O'Brien, says that you could actually see mo torcycles slow abruptly on the Day tona straightaway as oil piled up in the case, its viscosity embracing the fast-spinning flywheels as a liquid brake. A variety of fixes are used here: Scrapers close to the wheels peel off the oil and feed it to the pump: the flywheels may be turned down to provide extra room; underengine sumps are added, into which the oil falls; oil pickups are relocated.

Some designed-for-racing engines have terrible problems with crank case "weather." Oil and air get so in timately mixed by the stirring action of moving parts that no liquid pump can function effectively. Therefore, fair-sized vane air pumps are pro vided to pull out the air/oil mix, and send it to an oil separator. This not only scavenges the crankcase, it also pulls its pressure down. How much oil flow is really needed? A fresh, tight engine flows less oil than it will after wear has opened up the flow paths through main and rod bearings. The less oil the crank needs, the less oil there will be whizzing around in the case, causing problems. More oil is not always better.

Motorcycle engine designers have become very sophisticated recently in designing oil systems that always deliver oil, but this was not always so. As recently as the mid-1980s, en gines were still spinning rod bearings (the shell inserts, starved of oil, seized to the shaft and spun in the rod itself) because oil was either sloshing away from pump pickups or was ac cumulating in remote parts of the en gine in unpredictable ways, causing a disastrous fall in sump oil level.

In many auto-racing designs, the presence of high-G cornering forces obliges the designer to locate oil scav enge pumps at both ends of the case, and at both ends of each cambox. When cranks spin close to the oil level, screens or perforated windage trays are put between to discourage sloshing oil from reaching the crank. Some judicious "porting" may speed up oil return from valve gear to crankcase. Going for the last little Dits of reduction in oil and air drag, some builders have their cranks "streamlined," giving the whirling counterweights airfoil cross-sections. Others have the entire engine's inte rior coated with Teflon-like material intended to cause faster drain-back of the oil.

Is there really power to be had here? Well, the good ol' boys of NASCAR, at least. think so. The answers are resting comfortably in the dyno journals of all the major teams.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontSectional Harassment

January 1992 By David Edwards -

Leanings

LeaningsWind On the Chin

January 1992 By Peter Egan -

Letters

LettersLetters

January 1992 -

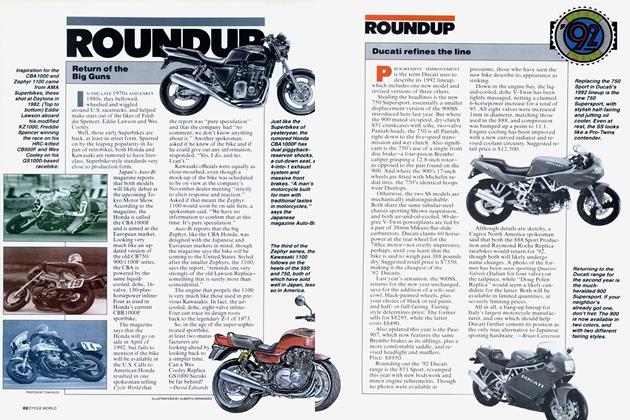

Roundup

RoundupReturn of the Big Guns

January 1992 By David Edwards -

Roundup

RoundupDucati Refines the Line

January 1992 By Brian Catterson -

Roundup

RoundupCw 25 Years Ago

January 1992 By Ron Griewe