CYCLE WORLD SERVICE

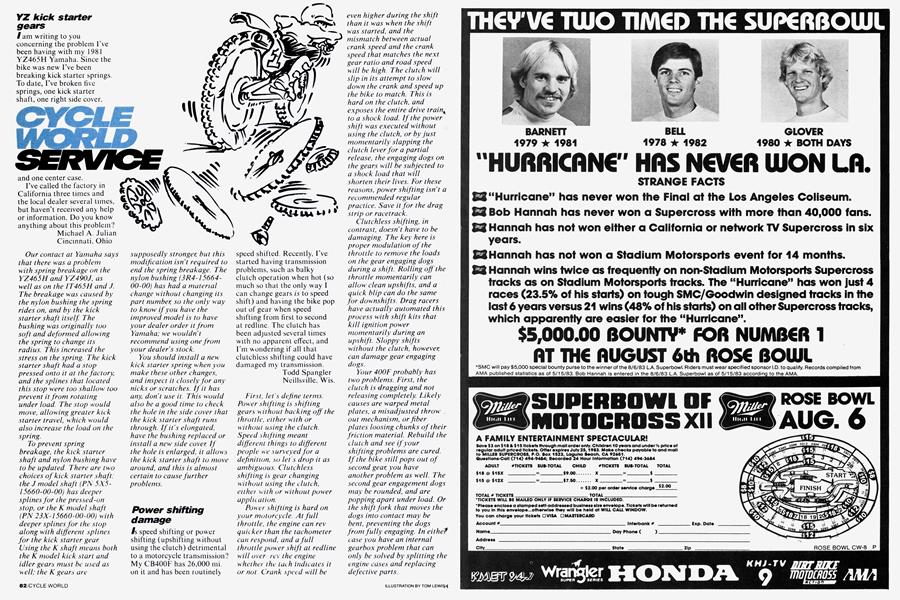

YZ kick starter gears

I am writing to you concerning the problem I've been having with my 1981 YZ465H Yamaha. Since the bike was new I've been breaking kick starter springs. To date, I've broken five springs, one kick starter shaft, one right side cover, and one center case.

I've called the factory in California three times and the local dealer several times, but haven't received any help or information. Do you know anything about this problem? Michael A. Julian Cincinnati, Ohio

Our contact at Yamaha says that there was a problem with spring breakage on the YZ465H and YZ490J, as well as on the IT465H and J. The breakage was caused by the nylon bushing the spring rides on, and by the kick starter shaft itself The bushing was originally too soft and deformed allowing the spring to change its radius. This increased the stress on the spring. The kick starter shaft had a stop pressed onto it at the factory, and the splines that located this stop were too shallow too prevent it from rotating under load The stop would move, allowing greater kick starter travel, which would also increase the load on the spring.

To prevent spring breakage, the kick starter shaft and nylon bushing have to be updated There are two choices of kick starter shaft: the J model shaft (PN 5X515660-00-00) has deeper splines for the pres sed-on stop, or the K model shaft (PN 23X-15660-00-00) with deeper splines for the stop along with different splines for the kick starter gear.

Using the K shaft means both the K model kick start and idler gears must be used as well; the K gears are supposedly stronger, but this modification isn't required to end the spring breakage. The nylon bushing (3R4-1566400-00) has had a material change without changing its part number, so the only way to know if you have the improved model is to have your dealer order it from Yamaha; we wouldn’t recommend using one from your dealer’s stock.

You should install a new kick starter spring when you make these other changes, and inspect it closely for any nicks or scratches. If it has any, don’t use it. This would also be a good time to check the hole in the side cover that the kick starter shaft runs through. If it's elongated, have the bushing replaced or install a new side cover. If the hole is enlarged, it allows the kick starter shaft to move around, and this is almost certain to cause further problems.

Power shifting damage

Is speed shifting or power shifting (upshifting without using the clutch) detrimental to a motorcycle transmission? My CB400F has 26,000 nii. on it and has been routinely speed shifted. Recently, I've started having transmission problems, such as balky clutch operation when hot (so much so that the only way I can change gears is to speed shift) and having the bike pop out of gear when speed shifting from first to second at redline. The clutch has been adjusted several times with no apparent effect, and I'm wondering if all that clutchless shifting could have damaged my transmission. Todd Spangler Ncillsville, Wis.

First, let’s define terms. Power shifting is shifting gears without backing off the throttle, either with or without using the clutch. Speed shifting meant different things to different people we surveyed for a definition, so let s drop it as ambiguous. Clutchless shifting is gear changing without using the clutch, either with or without power application.

Power shifting is hard on your motorcycle. At full throttle, the engine can rev quicker than the tachometer can respond, and a full throttle power shift at redline will over rev the engine whether the' lath indicates it or not Crank speed will be even higher during the shift than it was when the shift was started, and the mismatch between actual crank speed and the crank speed that matches the next gear ratio and road speed will be high. The clutch will slip in its attempt to slow down the crank and speed up the bike to match. This is hard on the clutch, and exposes the entire drive traink to a shock load. If the power shift was executed without using the clutch, or by just momentarily slapping the clutch lever for a partial release, the engaging dogs on the gears will be subjected to a shock load that will shorten their lives. For these reasons, power shifting isn’t a recommended regular practice. Save it for the drag strip or racetrack.

Clutchless shifting, in contrast, doesn’t have to be damaging The key here is proper modulation of the throttle to remove the loads on the gear engaging dogs during a shift. Rolling off'the throttle momentarily can allow clean upshifts, and a quick blip can do the same for downshifts. Drag racers have actually automated this process with shift kits that kill ignition power momentarily during an upshift. Sloppy shifts without the clutch, however, can damage gear engaging dogs.

Your 400F probably has two problems. First, the clutch is dragging and not releasing completely. Likely causes are warped metal plates, a misadjusted throw out mechanism, or fiber plates loosing chunks of their friction material. Rebuild the clutch and see if your shifting problems are cured.

If the bike still pops out of second gear, you have another problem as well. The second gear engagement dogs may be rounded, and are popping apart under load. Or the shift fork that moves the dogs into contact may be bent, preventing the dogs from fully engaging. In eithef case you have an internal gearbox problem that can only be solved by splitting the engine cases and replacing defective parts.

Plain vs. roller bearing

Mrtiat are the advantages and disadvantages of a roller bearing crankshaft compared to one with plain bearings? Porsche and BMW abandoned the press-fit, built-up roller crank some years ago, but still the Suzuki GS1100 uses it with success.

The Suzuki GS750 was redesigned with a plain bearing crank; does this mean all Suzukis will have plain bearings in the future? The questions I have are:

1 ) Are plain bearing cranks cheaper to manufacture? Is that why the Honda CB1100F is less costly than other 1100s?

2) In case of temporary oil failure, which crank will sustain less damage?

3) If there’s dirt or debris in the oil, which bearing type is more resistant to damage?

4) Which bearing type gives longer life, less friction, or less noise? Aaron Pascal Sherman Oaks, Calif.

A plain bearing crankshaft is less expensive to manufacture, can be manufactured to closer tolerances (giving less vibration), and is generally more rugged than a roller bearing crank. Mainly for these reasons, most new multi-cylinder motorcycle engines are being designed with plain bearing crankshafts, including all recent Suzuki models. We don’t expect this trend to change.

The main disadvantage of a plain bearing crankshaft is that it requires high pressure lubrication, and in the event of a disruption in the oil supply, it is more readily damaged than the roller bearing alternative. In return for this inconvenience, the plain bearings are more likely to pass debris without damage, are quieter, and offer at least the possibility of longer life. (It’s impossible to say in general whether a plain or roller bearing will last longer; it’s more dependent on the details of the design than on the bearing type.). The plain bearing crankshaft itself is stronger in torsion than a multi-piece pressed-together roller crank, and some motorcycles have twisted their roller cranks under strenuous use. the latest GSI 100s have the press-fit joints in their cranks welded to prevent crank twisting, and some Yamaha two-stroke GP racers have used single piece cranks with expensive split roller bearings for the same reason. (There’s no easy way to lubricate plain bearings in a twostroke crank, so two strokes will continue with roller bearings.)

There has been some interest from automotive companies recently in roller bearing cranks because roller bearings are more efficient than plain bearings. When you’re looking for the last bit of fuel economy, that may be important. It wouldn’t be too surprising to see the last multi-cylinder four-stroke motorcycle with a roller bearing crank roll off the production line about the >same time as the first hyper-economy ear with a roller bearing crank is announced.

Rusty cylinder

recently got water in the cylinders of my 1979 DTI25 Yamaha and the cylinder wall rusted. I would like to know the best method to remove this rust and if any other repairs would be Necessary to have the engine running at its peak again. Bert Vaillancourt, Jr. La Valle, Wis.

You need to buy the next-over-size piston and rings, and have the cylinder bored to fit. The only problem you may encounter is that the rust may be deep enough that an .010 in. (.25 mm) overbore may not remove it all. Accordingly, we’d recommend taking *your cylinder into a motorcycle service shop equipped to bore cylinders and ¿seeking their advice.

Emergency headlight

Twenty miles from town at 2 a.m. on a moonless night, my headlight died at 90+ mph. Luckily I was on a straight and stopped safely, but I was faced with problem because neither headlight beam worked. The situation was remedied, though, with the aid of my lighter and the motorcycle tool kit. I took the headlight out of its shell and plugged the turn signal leads into a hot receptacle in the wiring harness. Next I took the amber lens covers off the turn signals, and presto, I had dual headlights that were good for at least 45 «ïph. They got me home before I froze. R. Poirier International Falls, Minn.

View Full Issue

View Full Issue

More From This Issue

-

Departments

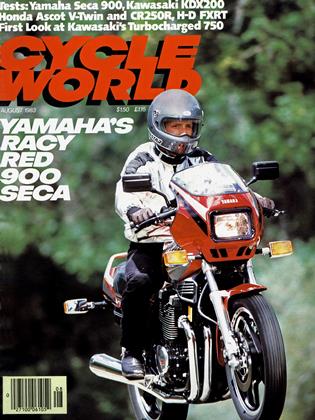

DepartmentsCycle World Up Front

August 1983 -

Letters

LettersCycle World Letters

August 1983 -

Departments

DepartmentsCycle World Roundup

August 1983 -

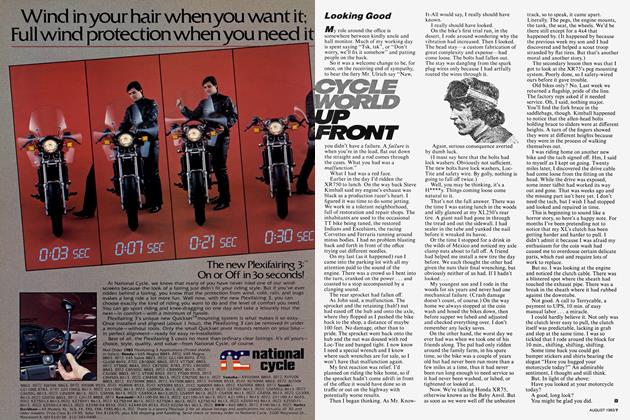

Competition

CompetitionHonda's New Racers

August 1983 By Allan Girdler -

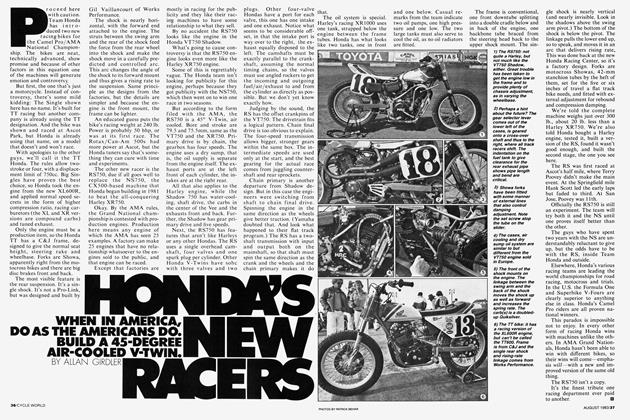

Technical

TechnicalA Hands-On Guide To Getting the Most Out of Adjusting Your Suspension

August 1983 By Steve Anderson -

Features

FeaturesParis-Dakar

August 1983 By Patrick Behar