Suzuki's Full Floating Single Shock Suspension System

John Ulrich

Looking at him, it's hard to imagine that Hirohide Tamaki is the man Iwho designed every World Championship-winning Suzuki motocrosser ever built. Tamaki, 43, is a small, quiet, unassuming man. Yet since joining the Suzuki Racing Department in 1961, Tamaki, now manager of the racing department, has designed all of the works motocrossers. The machines Kent Howerton used to win the 1980 AMA 250cc Championship originated on Tamaki’s drawing board.

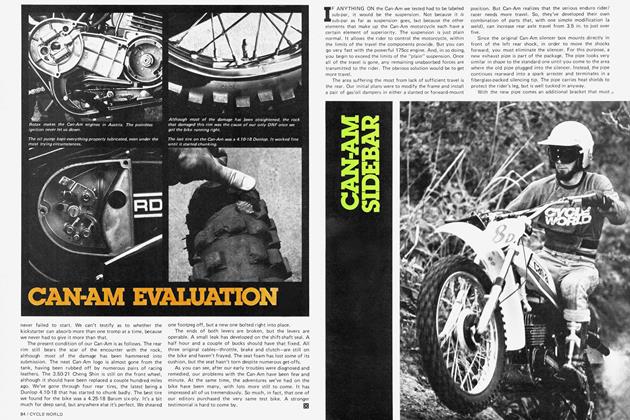

For the first half of the season, Howerton’s racebike was a conventional enough works racer. But for the last part of the season Howerton raced a single-rearshock machine. Tamaki designed the single-shock Suzuki system, called “Full Floating Suspension.”

During a recent visit by a journalist to the Suzuki factory, Tamaki talked about the Suzuki single-shock suspension system, now used on works motocrossers and works RD500 road racers, with adaptation to factory-supported Yoshimura F-l and endurance racers planned. Although

he didn’t say so, the system may see production on 1981 motocrossers as well.

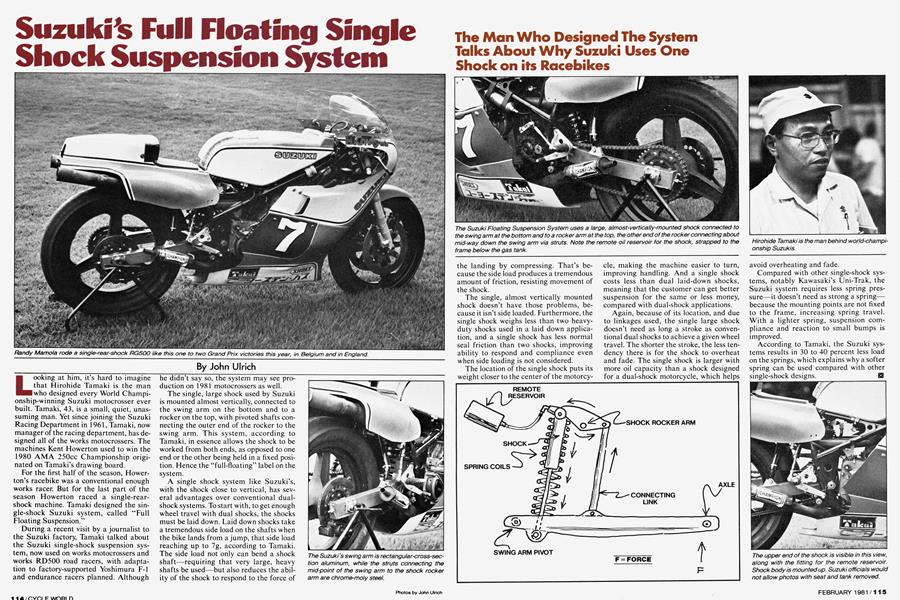

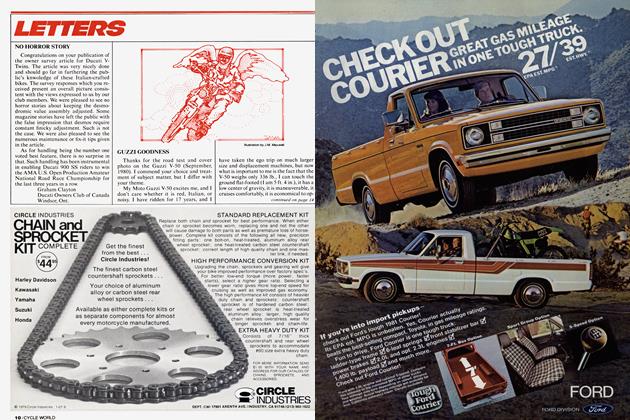

The single, large shock used by Suzuki is mounted almost vertically, connected to the swing arm on the bottom and to a rocker on the top, with pivoted shafts connecting the outer end of the rocker to the swing arm. This system, according to Tamaki, in essence allows the shock to be worked from both ends, as opposed to one end or the other being held in a fixed position. Hence the “full-floating” label on the system.

A single shock system like Suzuki’s, with the shock close to vertical, has several advantages over conventional dualshock systems. To start with, to get enough wheel travel with dual shocks, the shocks must be laid down. Laid down shocks take a tremendous side load on the shafts when the bike lands from a jump, that side load reaching up to 7g, according to Tamaki. The side load not only can bend a shock shaft—requiring that very large, heavy shafts be used—but also reduces the ability of the shock to respond to the force of the landing by compressing. That’s because the side load produces a tremendous amount of friction, resisting movement of the shock.

The Man Who Designed The System Talks About Why Suzuki Uses One Shock on its Racebikes

The single, almost vertically mounted shock doesn’t have those problems, because it isn’t side loaded. Furthermore, the single shock weighs less than two heavyduty shocks used in a laid down application, and a single shock has less normal seal friction than two shocks, improving ability to respond and compliance even when side loading is not considered.

The location of the single shock puts its weight closer to the center of the motorcycle, making the machine easier to turn, improving handling. And a single shock costs less than dual laid-down shocks, meaning that the customer can get better suspension for the same or less money, compared with dual-shock applications.

Again, because of its location, and due to linkages used, the single large shock doesn’t need as long a stroke as conventional dual shocks to achieve a given wheel travel. The shorter the stroke, the less tendency there is for the shock to overheat and fade. The single shock is larger with more oil capacity than a shock designed for a dual-shock motorcycle, which helps avoid overheating and fade.

Compared with other single-shock systems, notably Kawasaki’s Uni-Trak, the Suzuki system requires less spring pressure—it doesn’t need as strong a spring— because the mounting points are not fixed to the frame, increasing spring travel. With a lighter spring, suspension compliance and reaction to small bumps is improved.

According to Tamaki, the Suzuki systems results in 30 to 40 percent less load on the springs, which explains why a softer spring can be used compared with other single-shock designs. 13

View Full Issue

View Full Issue