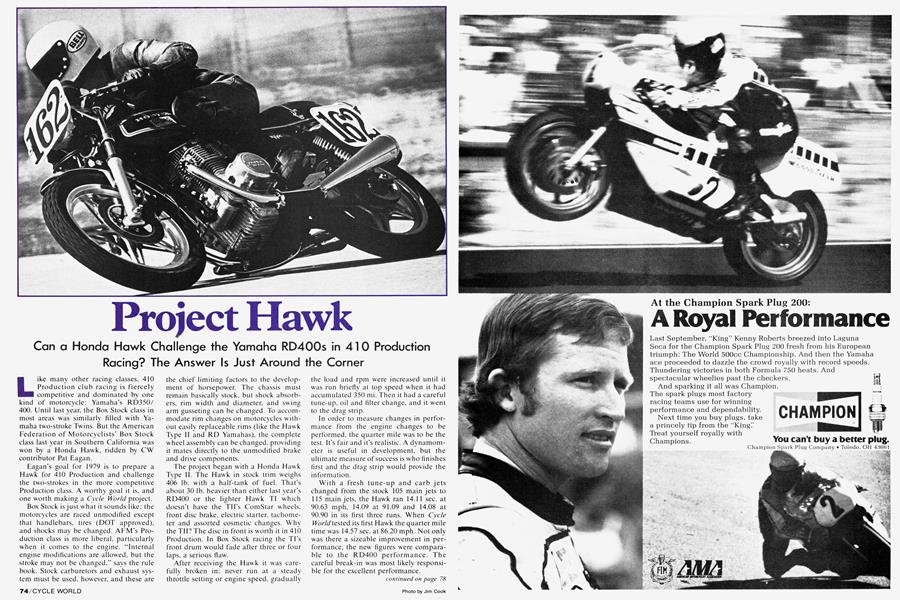

Project Hawk

Can a Honda Hawk Challenge the Yamaha RD400s in 410 Production Racing? The Answer Is Just Around the Corner

Like many other racing classes, 410 Production club racing is fiercely competitive and dominated by one kind of motorcycle: Yamaha's RD350/ 400. Until last year, the Box Stock class in most areas was similarly filled with Yamaha two-stroke Twins. But the American Federation of Motorcyclists' Box Stock class last year in Southern California was won by a Honda Hawk, ridden by CW contributor Pat Eagan.

Eagan’s goal for 1979 is to prepare a Hawk for 410 Production and challenge the two-strokes in the more competitive Production class. A worthy goal it is, and one worth making a Cycle World project.

Box Stock is just w hat it sounds like; the motorcycles are raced unmodified except that handlebars, tires (DOT approved), and shocks may be changed. AFM’s Production class is more liberal, particularly when it comes to the engine. “Internal engine modifications are allowed, but the stroke may not be changed,” says the rule book. Stock carburetors and exhaust system must be used, however, and these are the chief limiting factors to the development of horsepower. The chassis must remain basically stock, but shock absorbers. rim width and diameter, and swing arm gusseting can be changed. To accommodate rim changes on motorcycles without easily replaceable rims (like the Hawk Type II and RD Yamahas), the complete wheel assembly can be changed, providing it mates directly to the unmodified brake and drive components.

The project began with a Honda Hawk Type II. The Hawk in stock trim weighs 406 lb. with a half-tank of fuel. That’s about 30 lb. heavier than either last year’s RD400 or the lighter Hawk TI which doesn’t have the Til’s ComStar wheels, front disc brake, electric starter, tachometer and assorted cosmetic changes. Why the TII? The disc in front is worth it in 410 Production. In Box Stock racing the TI’s front drum would fade after three or four laps, a serious flaw.

After receiving the Hawk it was carefully broken in; never run at a steady throttle setting or engine speed, gradually the load and rpm were increased until it was run briefly at top speed when it had accumulated 350 mi. Then it had a careful tune-up. oil and filter change, and it went to the drag strip.

In order to measure changes in performance from the engine changes to be performed, the quarter mile was to be the test. It’s fair and it’s realistic. A dynamometer is useful in development, but the ultimate measure of success is who finishes first and the drag strip would provide the information.

With a fresh tune-up and carb jets changed from the stock 105 main jets to 115 main jets, the Hawk ran 14.11 sec. at 90.63 mph, 14.09 at 91.09 and 14.08 at 90.90 in its first three runs. When Cycle World tested its first Hawk the quarter mile time was 14.57 sec. at 86.20 mph. Not only was there a sizeable improvement in performance, the new figures were comparable to the RD400 performance. The careful break-in was most likely responsible for the excellent performance.

continued on page 78

continued from page 74

The next order of business was to get more horsepower. Quarter mile times for the race-winning RD400s run around 13 seconds flat at about 100 mph. That was the goal.

Finding the parts wouldn’t be easy. In order to build a motorcycle representative of club racing efforts, off-the-shelf parts would be used, rather than having custom parts made. But there have been exceptions.

Only two camshaft manufacturers. Norris and Mega Cycle, made cams for the Flawk when the project began. Because of the carb and exhaust restrictions, the mildest grind from each company was ordered. Timing of the two cams was very similar, but the Mega Cycle cam had 0.05Ö in. more lift than the Norris cam.

Jerry Branch of Branch Flow metrics offered to port the cylinder head. The amount of work needed, though, proved to be minimal. Branch said Honda had done a good job of designing the head; valve included angles and port angles were all good for gas flow. Also, because the combustion chamber is shallow, it promotes even combustion and good flame propagation. The head received a general cleanup; the only area relieved significantly was in the exhaust port. Because the valves weren’t shrouded. Branch predicted the porting job would increase flow no more than 6-7 percent. Valve shape wasn't changed, but the valves were highly polished.

Branch said there should be a minimum clearance of 0.060 in. between the intake valve and piston at TDC on overlap. Minimum clearance for the exhaust valve should be 0.040 in. Some clearance is obviously needed so the valves and pistons don't collide at high rpm. but Branch said that when the intake charge is entering the cylinder, it curves around the intake valve toward the valve relief in the piston and needs some room to enter.

To measure the clearance, we used rosincore solder. 0.080 in. thick. The solder was bent in U-shaped sections and placed over the valve reliefs in the pistons. Then the head went on. the camshaft turned, the valves opened and the solder depressed, showing how much clearance was left between the piston and the open valves. The soft solder, being rosin-core, is tubular and collapses easily enough so as not to bend valves or damage pistons. The Mega Cycle cam. with the most lift, still had 0.05Ó in. clearance on exhaust and 0.080 in. clearance on intake. No valve relieving need be done on the stock pistons.

Back at the drag strip, the Hawk was run with each cam. First came the Norris — 1370 Road Hawk. With the 115 main jets installed, the bike ran 13.96 sec. at 91.93 mph. 13.98 at 91.93. and 14.07 at 90.54. The Mega Cycle was tried first w ith stock jetting and ran 13.96 sec. at 94.24 mph. 13.87 at 94.43. and 13.85 at 94.24, a marked improvement. Because the bike felt a little flat in the mid-range, the 115 main jets w ere installed and the times w ere 13.68 sec. at 94.40. 13.71 at 94.83. and 13.68 at 94.53. The times had dropped four-tenths of a second and trap speed increased nearly 4 mph bv changing cams.

Next came the modified head. With the same Mega Cycle cam and 1 15 main jets installed, the bike consistently ran threetenths of a second slower and was dow n 5 mph in trap speed. Other main jets were tried, larger and smaller, and the times were worse. With the Norris cam mounted in the modified head, the times were fourtenths of a second slower and 4 mph low er. Apparently the larger exhaust port, when combined with the restrictive stock exhaust system, lowers port velocity and gives less power. The head w ill be tested on a Super Street Hawk later for evaluation w ith bigger carbs. open exhaust and larger displacement.

When the season opened at Ontario in February the Hawk was run with minimal changes. The Mega Cycle cam was installed. Graham Sheet Metal cafe racer handlebars replaced the stock bars. Dunlop K-81 tires were mounted and the turn signals and stands were removed as per requirements. That was it. The competition was highly modified and showed the benefit of previous years’ experience with the RD400s. Still. Eagan and the Hawk finished fourth, down on both power and cornering clearance compared to the fastest Yamahas, but quicker than the slower two-strokes.

continued on page 87

continued from page 78

The opening race pointed out the Hawk's shortcomings. Ground clearance must be improved. AFM rules allow repositioned exhaust systems for improved cornering clearance, but the Hawk uses what Honda calls a Power Chamber, a

large cross-over housing between the two exhaust pipes under the engine. The Power Chamber effectively prevents the exhaust system from being raised on the bike.

If the exhaust can’t be raised, the motorcycle needs to be raised with longer suspension components. Works Performance provided a set of long-travel shocks for the rear of the Hawk. Number 1 Products made two sets of damper rods, one 3A-m. longer than stock, the other 114-in. longer. New top bearings were made to regain lost engagement. To eliminate excessive (2-in.) fork spring sacking, 1-in. spacers were added at the top of the springs for preload. Different spring and damping rates will come later.

Ground clearance on the right side of the Hawk is limited by the brake lever. Worse, when in a righthand turn, leaned over all the way. the rear brake can't be used to slow the bike because it's already scraping. Alloy Graphics has fabricated a new brake lever and heli-arced a cable receiver on the rear drum backing plate, allowing repositioned footpegs.

At this time, there are no aftermarket brake pads available. If some are found, they will be tried. Stock brake parts are required, but different pads are allowed. The advantage to most stock pads is a reduction in fade. The rear brake is less important. A rear brake shouldn't fade and shouldn't be prone to locking. Control comes first: quick lap times are a result of control.

To take advantage of the increased angle of lean available, a set of racing slicks w ill be mounted. Theoretically, the slicks w ill give better traction for cornering, although sometimes the higher cornering forces resulting from the slicks can cause a normally good handling motorcycle to wobble. The only way to find out if the Hawk can handle the slicks is to try them.

Getting more power from this point on will be more difficult. A set of valve springs from Norris Cycle Products have been installed. The springs use a flat-wound harmonic damper-spring between the inner and outer springs. Titanium retainers are used with the Norris springs. The advantage of titanium retainers, besides the reduced weight, is a reduction in runin. Aluminum retainers normally seat-in 0.015 to 0.030 in. while titanium retainers don’t change size. Because off-the-shelf high-compression pistons aren't available yet for the Hawk, custom made pistons may be added.

With increased braking control, traction, cornering clearance, and some more power, the Hawk should be in the hunt.S