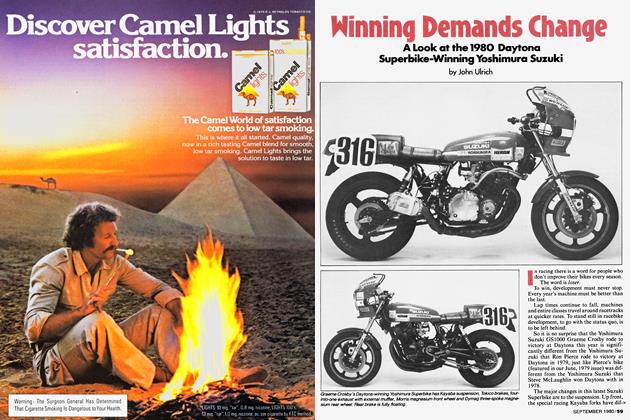

Yoshimura Suzuki GS1000 Superbike

John Ulrich

Look carefully at a competitive Superbike Production motorcycle and you'll see that it is much farther removed from its stock street origins than first glance would indicate. It has to be, considering that the bikes reach speeds above 150 mph, corner hard enough to drag engine cases on both sides, and brake with enough violence to lift the rear wheel at corner entrances. Still, just how much different these Street bikes-turned-racers really are isn't apparent until you take one apart piece by piece, asking questions all the way.

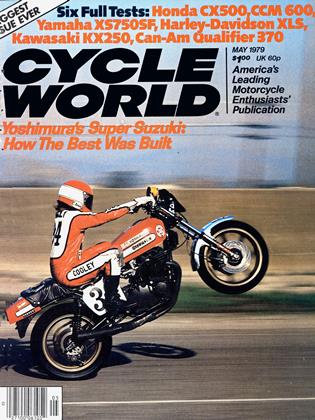

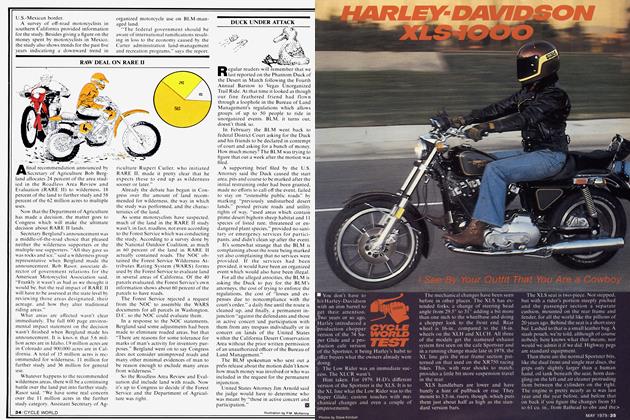

That’s what we did with the Yoshimura R&D of America Suzuki GSlOOO Superbike. It is obvious that the bike is potent. The Yoshimuras entered it in five AMA Superbike Production races in 1978; the Suzuki led all five and won three, with one dnf due to an oil cooler failure and another dnf when the sprocket bolts pulled out of the rear wheel. The bike is the fastest machine in the class and handles well enough to run away from the competition at twisty Sears Point, the toughest track on the AMA circuit.

After two days of test riding and discussion of the Yoshimura GSlOOO with Pops and Fujio Yoshimura and chief racing mechanic Suehiro Watanabe. we took the bike back to Cycle World's offices and dismantled it for photography and further inspection. What follows is what we learned:

Pops Yoshimura believes in extensive cylinder head porting and polishing. In finished form, his ports look more like modern art than a hunk of machinery. A view into a port reveals flowing lines and delicate shading patterns as light swirls onto the shimmering metal. The object is to remove flow-reducing rough cast surfaces and edges and straighten out curved sections. Yoshimura points out that at 10,000 rpm, the cylinder must be filled with a gas/air mixture in just 0.012 seconds, or 83.3 times per second. Intake port mixture velocity reaches more than 280 mph. Every turbulence-producing port defect effectively reduces the port area and decreases flow, and at high-rpm/highport-velocity, small defects are significant.

In his quest for maximum flow (and power), Pops increased the size of the valves. A stock GSlOOO has 38mm intake valves and 32mm exhaust valves; the Yoshimura GSlOOO, 39mm intake and 34mm exhaust. Total valve area is thus increased 8.5 percent. Each valve is shaped for better flow at the tulip area. Valve face angle is a conventional 45°. Stellite is welded onto the valve face and stem tip for hardness, while an overall nitride treatment reduces stem friction within the Yoshimura nickel-bronze valve guides. Again in the interests of maximum flow, valve stem diameter is reduced 0.4mm, from 7mm to 6.6mm—the narrower stem takes up less room in the port and allows better flow.

Heavy-duty valve springs, anodized aluminum retainers and special titanium keepers dimensionally identical to Honda keepers from the original CB750 (which are larger and shaped differently than the stock Suzuki keepers) replace the standard parts. Instead of the stock valve buckets with large adjustment shims riding between bucket and cam lobe, the Suzuki Superbike uses lightweight Yoshimura racing buckets with small adjustment shims located underneath. Radical camshafts tend to kick out stock shims at very high rpm, usually destroying the cylinder head in the process. That isn’t a problem with the shim moved underneath the bucket. What’s more, in combination with the other racing parts, the lighter buckets help reduce valve train weight by 40 percent.

Yoshimura’s own ductile cast iron billet camshafts are ground, heat treated and coated for compatibility with the racing valve buckets. Measured at 1mm valve lift (including 0.005 in. running clearance), the intake opens 26° BTDC and closes 56° ABDC, while exhaust opens 56° BBDC, and closes 26° ATDC. Intake lift is 10.4mm, exhaust lift 9.7mm.

Stock Suzuki cam sprockets are used, but the rubber dampers are removed and the bolt holes slotted to allow more precise cam timing.

Cam chain problems plagued the Yoshimura Suzuki early in the 1978 season, and it took time to come up with a cure. The race motor is capable of violently changing speeds, both accelerating and decelerating, creating waves in the roller cam chain, which can slightly alter the cam timing and send the valves crashing into the pistons. Modifying the stock automatic cam chain tensioner—which would back out and release tension at speeds above 10,000 rpm— didn’t help, even though a similar modification made to the Yoshimura 944cc GS750 Superbike had kept the cam chain under control. Unlike the GS750, the GSlOOO doesn’t have a cam chain idler roller between the cams, so the Yoshimuras welded aluminum plates to the cylinder head, machined them flat and installed a stock GS750 idler roller in the GSlOOO head. The change required use of a GS750 cam cover.

That modification seemed to work in Superbike Production sprint races, but the problem still surfaced in long endurance events. At the 1978 AFM Six-hour, the Yoshimura team was in contention for the win when the GSlOOO dropped its valves in the fourth hour, again due to slack in the cam chain.

The Yoshimuras found that the cam chain side plates wore into the Suzuki’s locked-in-place tensioner slippers, reducing tension as the rubber was ground off and the cam chain smoothed. So the mechanics polished the outside of the cam chain link plates with a buffer wheel and abrasive to remove the burrs normally present after the side plates are stamped out. Careful and thorough cleaning in solvent afterwards removed abrasive still on the chain.

The next step was to modify the long slipper which controls the cam chain’s forward descent from exhaust cam to crankshaft. After machining on each side of the face, the slipper only contacted the cam chain on the chain rollers, not the side plates.

But the modifications to the tensioner system that finally gave the Yoshimura Suzuki enough reliability to finish—and win—endurance races came in the form of a Kawasaki KZ1000 idler wheel, fitted into the cylinder head below the intake cam. With that second roller in place and the standard rear slipper tensioner shortened, machined on the edges (like the front slipper) and locked in place, the cam chain was steady and system wear wasn’t a problem. To accommodate the extra rollers, the Yoshimura racing cam chain used is one link longer than the stock cam chain, 61 links versus the standard 60.

The Yoshimuras use 11.5:1 compression ratio, standard-bore (70mm). pressure cast, two-ring pistons with flat tops, narrow squish bands and cut-away slipper skirts. According to Fujio Yoshimura. the cast piston expands more evenly than a forged piston and weighs less. (The Yoshimura piston weighs 8.0 oz.. compared to 7.5 oz. for a stock Suzuki piston and 8.5 for a leading standard-bore forged piston). Because the expansion is small and even. Fujio says, it is possible to use very small piston-to-cylinder tolerances (0.0015 in.) and minimize blow by and oil consumption in spite of the two-ring design. The slipper piston-skirt design results in less contact area and less friction generated. The compression ring is hard-chromed cast iron. Each wrist pin is nitrided to prevent seizure with the connecting rod small end. and standard circlips are used.

Making Horsepower Was Easy for Pops and Fujio, but Reliability and Handling Came Bit by Agonizing Bit. Here's How They Did it.

While manufacturers of forged racing pistons may disagree with the Yoshimura\s reasons for preferring cast pistons—and while many forged pistons are run at recommended clearances as small as the Yoshimura's 0.0015 in.—no one can argue the fact that the Yoshimura pistons work well and finish races.

The head gasket used in the Yoshimura Superbike is a standard Suzuki part. The Yoshimuras prefer the standard gasket because it is flexible enough to move with expanding cylinders and cvhnder heads, while they believe that solid copper racing head gaskets are too inflexible and mav lead to gas or oil leaks. The Yoshimura mechanics don’t use any sealers on head gaskets.

Worry about matching expansion rates of the crankcases, cylinders and cylinder head also motivates the Yoshimura practice of retaining the standard Suzuki cylinder studs. Pops feels that the rigidit\ and extreme torque applied to heavy-duty af-> termarket cylinder studs can damage crankcases at worst, and hinder normal expansion at best.

The stock Suzuki crankshaft is pressed together, with five roller main bearings and one ball bearing to take up lateral thrust. Built-up crankshafts are reliable in standard machines, but the pressed-together pieces often slip out of alignment at extraordinary rpm. The most common cure is to weld the crank pieces at the pressedtogether joints. But according to Fujio Yoshimura, welding the crankshafts can alter the heat treating and make the parts brittle in the area around the weld, as well as theoretically affecting crankshaft balance. Thus one might expect that when the Yoshimuras faced crank slip problems early-on during development of their GS1000, they would solve the problems in a novel way.

They did. The crankshafts used in Yoshimura Suzukis are built up of stock Suzuki parts, but are specially assembled at the Suzuki factory. In that assembly, the male crankshaft parts are dipped in Suzuki Super Lock (Suzuki’s brand name for a strong glue which hardens only in the complete absence of air), before being pressed together to a tolerance of less than 0.0012 in. That fix ended Yoshimura crankshaft troubles.

The one exception to the “stock parts” statement above is the number one cylinder crankshaft counterbalancer and alternator taper. The Suzuki cranks used by Yoshimura are made with a .75-in. shorter taper to work with a magneto. That allows the alternator cover to be shortened and beveled, the result being improved left side cornering clearance.

Once the assembled cranks are received from the factory, Pops polishes the counterweights and connecting rods, being careful not to change the balance, then removes all traces of abrasives.

Besides the cam chain and crankshaft difficulties, the Yoshimuras also faced clutch problems of various sorts. The first modification was to install heavy-duty racing clutch springs. According to Fujio, the GSlOOO’s clutch hub wouldn't have lasted another lap at Daytona in 1978, the bike’s first victory. The extra loads imposed by the racing motor would shear off the rivets holding the clutch basket to the clutch drive gear. Two things were done: The clutch hub securing rivets were increased in size and strength, and six heavy-duty damper springs replaced the stock combination of three heavy and three light damper springs.

There were other problems. Clutch plates slipped, warped, broke. The steel driven plates beat grooves into the aluminum clutch hub teeth, and with the plates imbedded into the clutch hub, the clutch wouldn’t disengage. At Sears Point, the clutch lasted on Wes Cooley’s Suzuki, but failed on Ron Pierce’s GS1000 while he led his heat race. Cooley led the final until the rear sprocket bolts pulled out of the Morris magnesium rear wheel hub, putting Cooley out with just three laps to go.

The Yoshimuras installed a Suzuki fivespoke WM-6 magnesium rear wheel originally made for Barry Sheene’s Suzuki RG500. The Suzuki wheel has more sprocket mounting bolts—a total of sevenspread on a larger diameter mounting circle than the Morris wheel and has a cushdrive as well. With the new wheel mounted, the Tsubaki #630 drive chain wouldn't clear the rear tire (a Goodyear D1997 3.75-18 slick), so the left edge of the tire had to be trimmed slightly with a razor blade. For 1979, the Yoshimura Suzuki’s rear wheel sprocket carrier was shimmed to allow greater chain/tire clearance.

While the new wheel assembly ended rear hub failures, clutch problems remained with the Yoshimuras to one degree or another until the day before the Suzuka Eight-Hour endurance race in Japan. A week of testing yielded nothing but disappointment and doubt that the bike could finish an endurance event. Finally, Suzuki engineers built a clutch hub out of steel, instead of aluminum, and produced a few sets of special clutch plates. The trick plates—developed for use in an RG500 dry clutch—are coated with paper-fiber friction material, and engagement tangs are formed by folding-over tabs cut thinner than the plate itself. (Stock tangs are the same thickness as the plate, and are solid). The folded tangs have a little give to work as dampers.

Those two modifications carried the day for the Yoshimura Suzuki, which won the endurance race at Suzuka and returned to the U.S. to win at Laguna Seca without clutch incident either time.

From the clutch, the GSlOOO’s power is directed through a Yoshimura close-ratio transmission with chrome-moly alloy gears. Gear teeth are polish-ground because the hard material is too tough for machine tools. Standard transmissions are machined by gear cutters. Gear dogs are undercut for more positive engagement, and all tolerances are minimal to avoid gear slop or drive-line snatch. Internal ratios are 33/17 (1.941:1) in first; 30/20 (1.500:1) in second; 28/23 (1.217:1) in third: 26/25 ( 1.040:1 ) in fourth; and 25/26 (0.960:1) in fifth. The retail price of the transmission alone is $850.

Carburetors are 31mm aluminum-body Keihin CRs. Made for racing, the CR carbs have smooth bores to eliminate turbulence caused by the protruding jets and fittings present in standard carburetors. Such turbulence can reduce the effective diameter of a carburetor throat. Because the CRs are designed for racing use only, the engineers who built them were not concerned with operation at less than half-throttle. While a slow-speed circuit is present in the carburetor bodies, there isn’t an idle circuit. Besides the large nominal size and smooth bore, the CRs have good needle and main jet accessibility for fast changes at the racetrack—a mechanic can rejet the carbs without removing them from the motorcycle.

The 4-into-l exhaust system is handbent because a pipe made by hand can be built to more precise dimensions with smoother bends—and thus better exhaust flow—than a maehine-bent pipe. The Yoshimuras fit different pipes for different kinds of racetracks. Longer head pipes produce more low-end and mid-range power for shorter and tighter tracks like Sears Point, Laguna Seca and Loudon. Shorter head pipes deliver more top-end power and speed for fast tracks like Daytona and Pocono. The tail section remains unchanged at all tracks. The entire exhaust system is tucked in so well that it has survived crashes without damage, which can mean one less thing to fix if the bike is crashed in a heat race or practice before the main event.

The Kokusan Denki CDI ignition system is powered by a magneto mounted on the left side of the crankshaft. A magnetically-triggered pulsar on the right side of the crank is connected to a black box which calculates advance and triggers Kokusan Denki coils, which produce 30.000 volts throughout the rpm range and which will fire across plug gaps of up to 0.060 in. The pulsar is protected by the stock points cover, which is extensively drilled to admit eooling air—the pulsar must be kept cool to maintain signal accuracy. Ignition timing starts at 14.5° BTDC at 500 rpm, advancing to 20° at 2250 rpm, 29.5° at 3000 rpm. 36° at 5000 rpm. and 37° at 7000 rpm. which is the point of full advance. The bike is fitted with ND 31 LPT racing spark plugs for warm-up and racing at all tracks, with gaps set at 0.035 0.040 in.

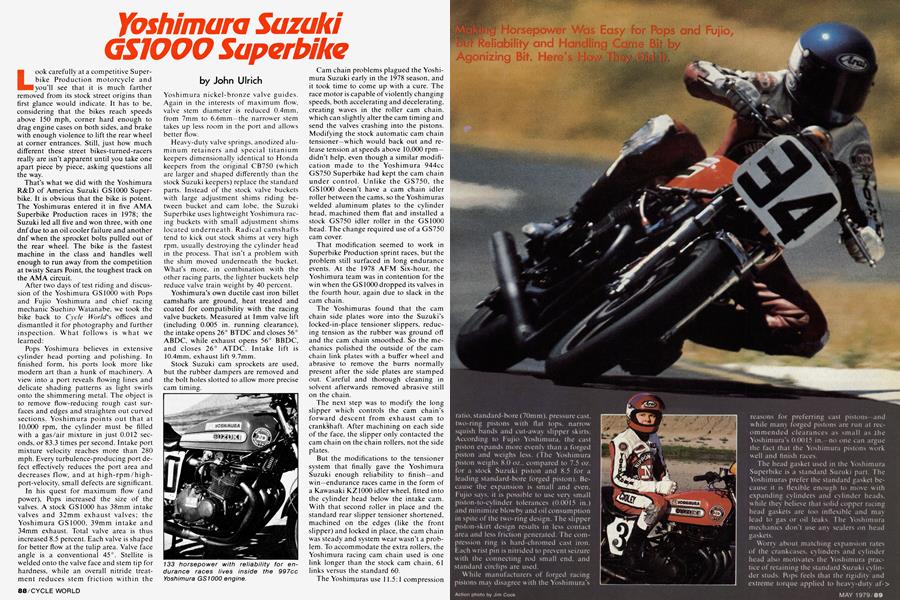

All told, the modifications made by Yoshimura increase the GSlOOO's power output to 133.54 bhp at 10,000 rpm and 76.64 ft. lb. of torque at 8000 rpm, measured at the countershaft sprocket on the Yoshimura R&D dyno. Output readings on one dyno may not match those achieved on another dyno. What is important is that the engine makes more power than its competition, is plenty fast enough to win races, is capable of lasting long enough to reach victory circle.

As expected, all that power produces a lot of extra heat, and extraordinary measures are necessary to keep the engine from melting into a pile of slag. The engine eases, cylinders, cylinder head and cam cover are all treated with Kal-Gard. a greyblack coating originally developed to protect weapons carried by underwater demolition crews from the effects of salt water. Testing showed that the material could be used for other things, including increasing engine heat dissipation.

Blasting the parts with aluminum oxide increases surface area five times, an increase visible only under magnification. The Kal-Gard coating, which is only 0.0003 in. thick after spray application and baking, follows the microscopic contours created in the metal by the aluminum oxide blasting. The coating helps dissipate heat into the surrounding air or airstream. causing a typical engine to run 15 percent cooler. Only external surfaces are coated and treatment of a Japanese Four runs about $95.

Yoshimura’s efforts to keep the engine cool involved much more than engine coating. The air passages present between the stock cylinder bores are hogged out for more air flow; Ts-in. holes are drilled through cylinder and cylinder head fins to eliminate stagnant air pockets between fins and to induce cooling air turbulence; and holes are drilled into the cylinder head around each spark plug to increase the surface area available for heat radiance. An all-aluminum ND oil cooler rubbermounted on the front frame downtubes is fed by a full-flow Yoshimura fitting which replaces the stock oil pressure sender unit plate and diverts the oil flow. The ND cooler was fitted with 16mm o.d. rubber hose for 1978. but AMA rules require braided stainless steel lines and fittings for 1979. Early last year, the Yoshimura bikes all ran coolers from Earl’s Supply with stainless steel lines. After cooler failures at > Daytona (on the Yoshimura Kawasaki) and Loudon (on the GS1000). the change was made to the ND cooler and rubber lines.

The switch to rubber lines was made at the same time as the changeover to the ND cooler because that’s what the ND cooler was designed to accept. The Yoshimuras don’t know if the more rigid stainless steel lines had anything to do with the earlier failures of Earl's Supply coolers. Cooler mounting position could have influenced the failures, since the coolers were mounted to the lower fork triple clamp on each bike at Daytona and Loudon, and moved back into the more protected frame position after those dnfs. Coolers mounted on triple clamps are vulnerable to damage from small stones kicked up by other bikes.

The ND cooler was obtained for the Yoshimuras by the Suzuki factory, and is not at this time available in the United States.

Throughout 1978. the Yoshimuras used 30w Castrol R (bean oil). Pops picked 30w after dyno tests showed that using 40\v cost about 1.5 horsepower, while 20w didn't have enough film strength for safe high rpm. high stress operation. For 1979. a new sponsorship agreement was reached with Bel-Ray. and the Yoshimura Superbikes will be running Bel-Ray 30w Racing Motor Oil. >

Having an engine that makes power, stays together and doesn't overheat is a big part of a successful Superbike effort. Equally important is a quality sometimes more difficult to obtain—handling. The Yoshimuras have obviously sorted out their GS1000, as its performance on short, difficult tracks has shown. The frame itself is not as heavily modified as one might expect. There is no additional front frame section bracing, and the steering head area is left stock. An oil cooler mount is welded to the frame downtubes,but does not affect frame rigidity. Engine mounts and mount bolts are all stock Suzuki parts. A tab for the shift linkage is welded onto the left bottom engine cradle tube, and rearset footpeg mounts are welded onto the sw ing arm mount gussets just below' the swing arm pivot.

There is. however, significant bracing work done on the rear of the frame and

swing arm. Mild carbon steel tubing (22mm o.d.) is brazed into position across the rear frame downtubes at the enginemount/swing arm-mount gussets, above the swing arm pivot. The tube prevents frame twisting caused by the torque of the drive chain pulling the rear sprocket and left side of the swing arm. Shorter pieces of the same tubing are welded across the bottom of the triangle formed by the rear frame downtubes. rear section top tubes > and shock absorber mount tubes. Upper shock absorber mounts are relocated to provide 54.5° of shock laydown angle, and 1 1mm o.d. tubes are welded in behind the gusseted new upper shock mounts and the rear section top tube of the frame. The additional tubes and bracing of the rear section are necessary to handle the increased loading caused by the laydown shock position. Alignment of shocks and shock absorber mounts is critical.

continued from page 101

A bridgework of 22mm tubing is built across and along the bottom of the stock Suzuki swing arm to minimize flexing. However, at the Suzuka eight-hour, a braced frame with laydown shocks and a totally stock swing arm was used without handling problems resulting, implying that swing arm bracing is in fact unnecessary. at least at that racetrack. In any case, the fact that the drive chain grinds on the left side swing arm bracing under certain suspension load conditions doesn't seem to affect the handling or stability of the U.S. Superbike.

For the 1979 season, the Yoshimura Suzukis will have additional front engine mount gusseting. That's because the frame used at Suzuka cracked less than one hour before the end of the endurance race, causing the bike to wobble. The Yoshimuras theorize that the break was caused because the straight right engine mount transmits engine vibration directly to the frame downtube, and the strain of eight racing hours was too much for the mild steel to take. The left engine mount, on the other hand, has a bend in it. which would tend to absorb, rather than transmit, vibration.

continued on page 113

continued from page 104

The shock absorbers are gas-charged. 13 in. long, made by Kayaba and feature six damping adjustment positions, five preload positions and a choice of six springs, with two springs used together. One shorter and lighter spring handles small and initial jolts, while a longer and stronger spring comes into play in the case of secondary reaction and large bumps. There are 270 possible shock damping, preload and spring combinations.

The Kayaba air forks are even more> complex in the possible adjustments and number of potential combinations. The triple clamps are stock Suzuki parts. The aftermarket forks started out with standard length tubes, but the Yoshimuras lengthened the tubes 35mm bv welding on pieces cut from a spare fork tube. The extra tube length increases rake bv half a degree, from 26.5 to 27 . and changes trail from 4.57 in. (for the stock GS1000E) to 5.90 in., though the steering head is not modified.

I he geometry changes contribute to top speed stability while the extra fork tube length increases the height of the engine side covers relative to the ground, thus improving cornering clearance as well. Spacers inside the fork tubes compensate for the lengthened tube and determine spring preload.

Stock air caps are connected to a single Goki air balance fitting mounted on the upper triple clamp behind the steering head. Fork air pressure is normally set somewhere between 14 and 20 psi.

Fork oil viscosity and level are both variable. The Yoshimuras measure the quantity of oil in each fork with a calibrated dip stick, removing the caps and springs and collapsing the forks before each reading. Level is varied b\ remov ing oil with a suction gun or bv adding oil from a burette.

Maximum fork travel is 5.7 in. ( 145mm). but the Yoshimuras try to set the forks up to deliver 5-5.3 in. ( 130-135mm) travel at each track. Various fork adjustments can be made necessary by rider weight, track surface, ambient temperature, available traction (which affects possible braking force) and even riding style. Setting up the front suspension is in itself an exacting and time-consuming job. and must be done in concert with rear suspension adjustments. It's not surprising that the Yoshimuras usually need an entire practice day to tune the suspension on a track they haven't raced on before.

The mechanics begin bv setting fork ride height, (with the motorcycle stationary and off the stand with the rider aboard), at 1.6 in. (40mm) less than full extended length. Air pressure largely determines ride height. The Yoshimuras find that another 2.8-3.9 in. (70-100mm) of travel should be used on turns, bumps, and under braking, but getting the desired amount of dynamic travel isn't as simple as setting static air pressure or spring preload.

For example, air pressure not only sets ride height, but also determines resistance to fork bottoming under braking. As the fork compresses, air pressure increases progressively and offers more resistance to further compression. Too much static air pressure w ill reduce travel and induce front wheel chatter in the corners.

Air quantity also comes into effect, since a larger volume at a given beginning psi will offer a different compression resistance curve, relative to travel, than a smaller volume at the same beginning psi. Fork oil level determines air volume in the forks. Oil quantity in each fork leg. then, sets the amount of fork travel under braking. If the rider complains of too much fork dive under braking, adding oil will reduce air volume and induce greater pressure increases—and resistance to dive and bottoming—per unit of fork travel distance.

Initial loads are taken b\ the springs, and so spacer length (and thus, spring preload) determines reaction, to the point where air compression resistance takes over the major part of reaction control.

Fork damping action is affected by fork oil weight, w hich varies from 5w to 30w (in increments of five), depending upon the track and conditions. The Yoshimuras use Bel Ray Racing Fork Oil.

It’s easy to see that the possible combinations presented by the four major fork adjustments—spring preload, air pressure, oil level, oil weight—are almost infinite even in practical use. Another possible alteration would be spring rating, but that isn’t one currently used by the Yoshimuras.

Steering lock is limited by 6mm Allen head screws with locking nuts fitted into the stock lower triple clamp and a KYB steering damper with six damping adjustment positions helps stabilize and control the steering in the event of marginal control situations (as when the rider gets on the gas too hard exiting a turn and the rear end steps out violently.)

The handlebars are from Graham Sheet Metal (GSM), the grips from American Pro, the quick quarter turn throttle from Magura and the easy-to-use-in-mid-race clutch adjuster mechanism and the tachometer (with 10,500 rpm redline) from an RG500.

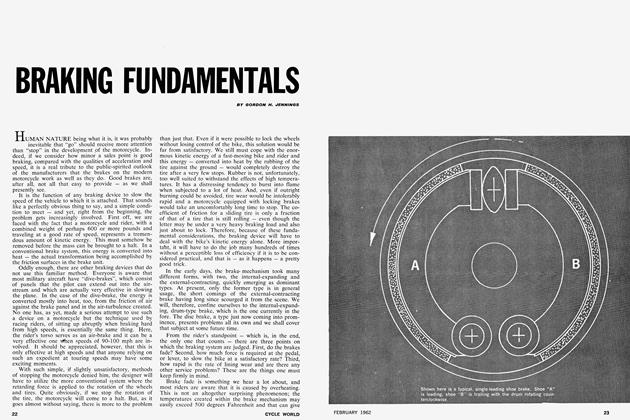

The front brake master cylinder and calipers are Lockheed. Braided stainless steel lines from Earl’s Supply are ‘/4-in. outside diameter. Front brake discs are Suzuki, drilled for lightness and to reduce warpage. The Yoshimuras used plasmasprayed aluminum discs early in the season.” but found that the discs warped seriously—which reduced braking power— during races. Undrilled stock discs also warped, but the drilled discs haven't caused any problems. The discs are not thinned.

Non-floating rear brakes restrict rear suspension movement when applied, often causing wheel hop and resultant instability at corner entrances. That makes it difficult or impossible to use the rear brake hard all the way into a turn apex or to throw the motorcycle into a corner. So the Yoshimura GS1000 has a floating rear brake—the caliper mounting plate is anchored to the frame, not the swing arm, and the mount is free to pivot (on needle roller bearings) on the axle. The floating brake doesn’t eliminate the problem completely, but does improve it about 90 percent. The rear master cylinder and disc are standard Suzuki. Yoshimura mechanics fabricated the mounting plate and installed an American bearing.

After Cooley took the checkered flag last year at Laguna Seca. Yoshimura mechanics went to push the bike into victory circle and found that the front brakes had locked. It took three men to move the machine into place. Later examination revealed no mechanical malfunction, and Fujio Yoshimura blamed the problem on the use of brake fluid which had absorbed excessive amounts of water during rainy races at Ontario (the AFM six-hour) and Pocono (the AMA Superbike Production event which Cooley also won). The fluid hadn’t been changed since Daytona. After Laguna Seca, the Yoshimuras switched to BelRay DOT 5 silicone-base brake fluid and report no problems with water absorption in practice sessions since then.

The WM-4 19-in. front wheel is cast in magnesium by Morris and carries a Goodyear 3.25-19 slick.

The gas tank is stock, and the seat at least started life as a Suzuki part. The steel pan and vinyl cover are retained, but the padding is removed and sheet aluminum used to shape a bucket to help the rider hang on during acceleration and at top speed. Minimal padding is used at the front of the seat, which lowers the rider about four inches. Superbike rules for 1979 require (as of this writing) stock seat profiles, which should provide quite a few spectator (and pilot) thrills on the faster tracks. >

Yoshimara Sazaki GS1000

SPECIFICATIONS

$10,000

The crankcase breather tank is actually a discarded brake fluid can with tubes running from the cam cover breather to the tank, and then to the atmosphere behind the seat. A tiny six-volt minibike battery mounted on a drilled sheet metal cage on the forw ard part of the rear fender powers the AMA-required functioning taillight. A toggle switch on the left side plate turns the power source on and oft'. Number plates are sheet aluminum.

Ready-to-race with a full tank of gas, the Yoshimura Superbike weighs 450.5 lb. Add a 140-lb. rider and the bike has a power to weight ratio of just 4.42 lb./bhp. Compare that to a stock GSlOOO's 8.14 lb./bhp; a stock Honda CBX's 6.99 lb./bhp; and a KZ 1300's 6.93 lb./bhp.

That’s why Superbikes are what they are and do what they do, and that's why the Yoshimura GSIOOO Suzuki wins races.