A LEADING QUESTION

Nobody Doubts that Today’s Leading Axle Forks Work Best. But the Reasons are So Obvious They’re Hard to Understand.

Lane Campbell

When this article was commissioned the folks at CYCLE WORLD indicated they expected something mysterious and exotic. Lots of old-world theory and dazzling science and such. Turns out it didn't happen. The reasoning behind today’s leading axle forks is so simple that this researcher was reminded mostly of the first time he was asked why the chicken crosses the road. I wracked my 8-year-old brain because there just had to be some answer more profound than to get to the other side.

So begins our classic fork joke: Why move the front axle off the center line? To get it out of the way. That’s all.

Sure, I know certain trials bikes use a leading axle slider on otherwise standard forks to shorten the trail, but that’s just good parts-bin engineering. Sure, Hatta made some units for the Kawasaki Bighorn with a choice of forward or center (or rearward, even) mount, but that was parts-bin engineering, too. With today’s super-long-travel fork units, geometry has little to do with the choice of axle location. The axle is mounted out there in front of the slider to give the forks more room to work.

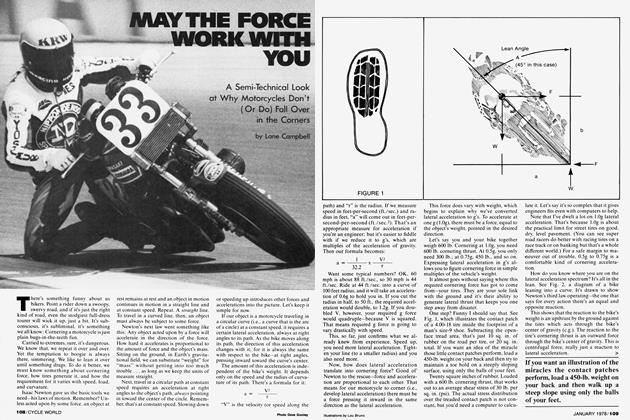

To visualize this, let's lay out a motorcycle front end on paper and subject it to a little cold scrutiny. You’ll begin to see the constraints a fork designer faces in sizing his units.

There’s a top and bottom limit to the sketch. The bottom, of course, is the ground; the top is the bike’s steering head. The front suspension exists primarily to maintain a connection between the steering head and the ground, no matter how much either may pitch and gyrate. It does so through the medium of fork travel, and (so far at least) more travel equals better.

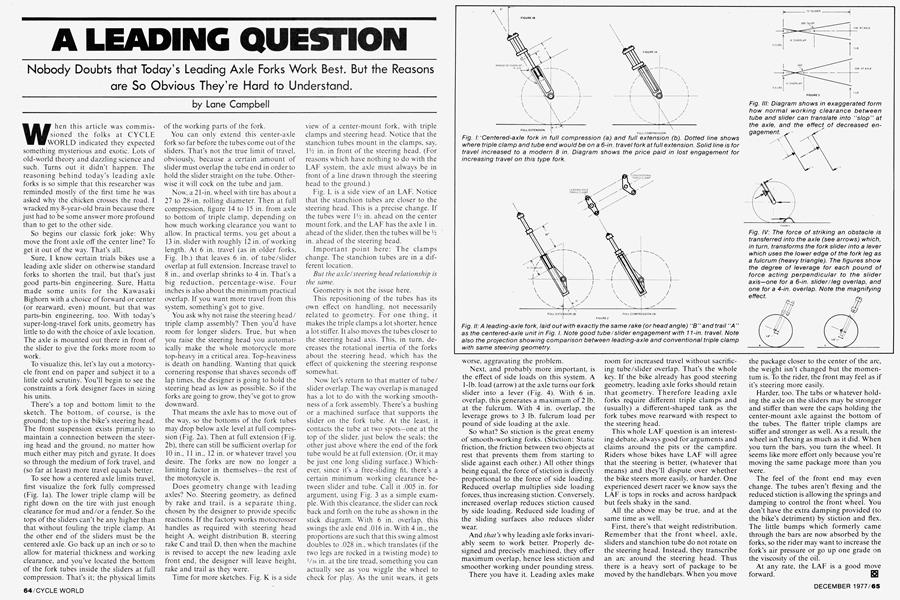

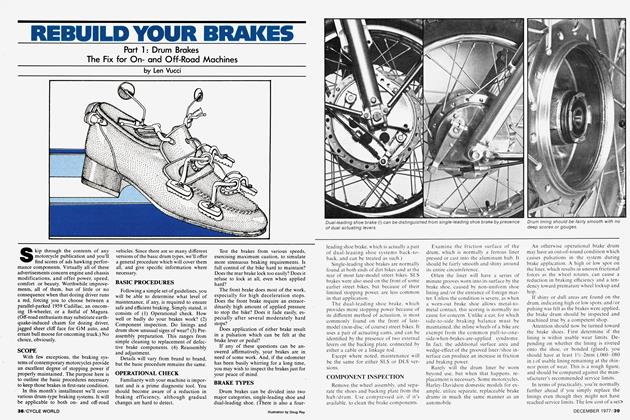

To see how a centered axle limits travel, first visualize the fork fully compressed (Fig. la). The lower triple clamp will be right down on the tire with just enough clearance for mud and/or a fender. So the tops of the sliders can’t be any higher than that without fouling the triple clamp. At the other end of the sliders must be the centered axle. Go back up an inch or so to allow for material thickness and working clearance, and you’ve located the bottom of the fork tubes inside the sliders at full compression. That’s it; the physical limits of the working parts of the fork.

You can only extend this center-axle fork so far before the tubes come out of the sliders. That’s not the true limit of travel, obviously, because a certain amount of slider must overlap the tube end in order to hold the slider straight on the tube. Otherwise it will cock on the tube and jam.

Now', a 21-in. wheel with tire has about a 27 to 28-in. rolling diameter. Then at full compression, figure 14 to 15 in. from axle to bottom of triple clamp, depending on how much working clearance you w'ant to allow'. In practical terms, you get about a 13 in. slider w ith roughly 12 in. of working length. At 6 in. travel (as in older forks, Fig. lb.) that leaves 6 in. of tube/slider overlap at full extension. Increase travel to 8 in., and overlap shrinks to 4 in. That’s a big reduction, percentage-w'ise. Four inches is also about the minimum practical overlap. If you want more travel from this system, something’s got to give.

You ask why not raise the steering head/ triple clamp assembly? Then you’d have room for longer sliders. True, but when you raise the steering head you automatically make the whole motorcycle more top-heavy in a critical area. Top-heaviness is death on handling. Wanting that quick cornering response that shaves seconds off lap times, the designer is going to hold the steering head as low as possible. So if the forks are going to grow, they’ve got to grow' dowmward.

That means the axle has to move out of the way, so the bottoms of the fork tubes may drop below axle level at full compression (Fig. 2a). Then at full extension (Fig. 2b), there can still be sufficient overlap for 10 in., 11 in., 12 in. or whatever travel you desire. The forks are now no longer a limiting factor in themselves—the rest of the motorcycle is.

Does geometry change with leading axles? No. Steering geometry, as defined by rake and trail, is a separate thing, chosen by the designer to provide specific reactions. If the factory works motocrosser handles as required with steering head height A, weight distribution B, steering rake C and trail D. then wfien the machine is revised to accept the new leading axle front end, the designer will leave height, rake and trail as they were.

Time for more sketches. Fig. K is a side view' of a center-mount fork, with triple clamps and steering head. Notice that the stanchion tubes mount in the clamps, say,

1 Vi in. in front of the steering head. (For reasons w hich have nothing to do with the LAF system, the axle must always be in front of a line drawm through the steering head to the ground.)

Fig. L is a side view' of an LAF. Notice that the stanchion tubes are closer to the steering head. This is a precise change. If the tubes were Vh in. ahead on the center mount fork, and the LAF has the axle 1 in. ahead of the slider, then the tubes will be Vi in. ahead of the steering head.

Important point here: The clamps change. The stanchion tubes are in a different location.

But the axle/steering head relationship is the same.

Geometry is not the issue here.

This repositioning of the tubes has its own effect on handling, not necessarily related to geometry. For one thing, it makes the triple clamps a lot shorter, hence a lot stiffen It also moves the tubes closer to the steering head axis. This, in turn, decreases the rotational inertia of the forks about the steering head, which has the effect of quickening the steering response somewhat.

Now let’s return to that matter of tube/ slider overlap. The way overlap is managed has a lot to do with the working smoothness of a fork assembly. There’s a bushing or a machined surface that supports the slider on the fork tube. At the least, it contacts the tube at two spots—one at the top of the slider, just below the seals; the other just above where the end of the fork tube w'ould be at full extension. (Or, it may be just one long sliding surface.) Whichever, since it’s a free-sliding fit, there’s a certain minimum working clearance between slider and tube. Call it .005 in. for argument, using Fig. 3 as a simple example. With this clearance, the slider can rock back and forth on the tube as shown in the stick diagram. With 6 in. overlap, this swings the axle end .016 in. With 4 in., the proportions are such that this sw ing almost doubles to .028 in., which translates (if the tw'o legs are rocked in a twisting mode) to 1 /16 in. at the tire tread, something you can actually see as you wiggle the wfieel to check for play. As the unit wears, it gets worse, aggravating the problem.

Next, and probably more important, is the effect of side loads on this system. A 1-lb. load (arrow) at the axle turns our fork slider into a lever (Fig. 4). With 6 in. overlap, this generates a maximum of 2 lb. at the fulcrum. With 4 in. overlap, the leverage grows to 3 lb. fulcrum load per pound of side loading at the axle.

So what? So stiction is the great enemy of smooth-working forks. (Stiction: Static friction, the friction between two objects at rest that prevents them from starting to slide against each other.) All other things being equal, the force of stiction is directly proportional to the force of side loading. Reduced overlap multiplies side loading forces, thus increasing stiction. Conversely, increased overlap reduces stiction caused by side loading. Reduced side loading of the sliding surfaces also reduces slider wear.

And that’s why leading axle forks invariably seem to work better. Properly designed and precisely machined, they offer maximum overlap, hence less stiction and smoother working under pounding stress.

There you have it. Leading axles make room for increased travel without sacrificing tube/slider overlap. That’s the whole key. If the bike already has good steering geometry, leading axle forks should retain that geometry. Therefore leading axle forks require different triple clamps and (usually) a different-shaped tank as the fork tubes move rearward with respect to the steering head.

This whole LAF question is an interesting debate, always good for arguments and claims around the pits or the campfire. Riders whose bikes have LAF will agree that the steering is better, (whatever that means) and they’ll dispute over whether the bike steers more easily, or harder. One experienced desert racer we know says the LAF is tops in rocks and across hardpack but feels shaky in the sand.

All the above may be true, and at the same time as well.

First, there’s that weight redistribution. Remember that the front wheel, axle, sliders and stanchion tube do not rotate on the steering head. Instead, they transcribe an arc around the steering head. Thus there is a heavy sort of package to be moved by the handlebars. When you move the package closer to the center of the arc, the weight isn’t changed but the momentum is. To the rider, the front may feel as if it's steering more easily.

Harder, too. The tabs or whatever holding the axle on the sliders may be stronger and stiffer than were the caps holding the center-mount axle against the bottom of the tubes. The flatter triple clamps are stiffer and stronger as well. As a result, the wheel isn’t flexing as much as it did. When you turn the bars, you turn the wheel. It seems like more effort only because you’re moving the same package more than you were.

The feel of the front end may even change. The tubes aren’t flexing and the reduced stiction is allowing the springs and damping to control the front wheel. You don’t have the extra damping provided (to the bike’s detriment) by stiction and flex. The little bumps which formerly came through the bars are now absorbed by the forks, so the rider may want to increase the fork’s air pressure or go up one grade on the viscosity of the oil.

At any rate, the LAF is a good move forward. 13