..TIRES

GORDON H. JENNINGS

IT HAS BEEN SAID, and with great accuracy, that without the pneumatic tire we would all still depend on the railroad and horse-drawn wagons for transportation; the motorcycle and automobile could never be more than impractical toys without this inflated rubber and fabric ring between their wheels and the ground. Many substitutes have been tried; none of them have been successful — for reasons we shall explain in due course.

Credit for the invention of the pneumatic tire goes to John Dunlop, who had wearied of the jolting that he got when riding his bicycle through the cobblestone streets of Dublin and invented the “tyre” to improve the bike’s ride. That was in 1888, and although Dunlop’s tire was quite successful in cushioning his passage over the cobblestones, it was not until the invention was applied to the motor vehicle that its true worth came to light.

To fully understand the usefulness of Dunlop’s invention, consider what the motorcycle would be like without it. Obviously, without the excellent cushioning provided by the pneumatic tire, even the best suspended of bikes would rattle its rider around severely, and the bare steel wheels would set up an intolerable clatter. Traction, too, would present difficulties: steel’s coefficient of friction is not very high, and a lot of skidding would be inevitable. However, the most serious problem would occur in cornering. The steel wheel would give absolutely no warning that the machine was nearing the limit of adhesion and the rider would have to rely entirely on experience, which would have to be acquired in a most painful manner, to tell him how fast a corner could be negotiated.

The pneumatic tire overcomes all of these difficulties. It is a good cushion, because it will deform enough to envelop most small road irregularities and take much of the jolt out of the larger ones. It offers good traction, as rubber’s coefficient of friction is very good. And, finally, it provides a large measure of stability under acceleration, braking and cornering — and this last property is the pneumatic tire’s most valuable asset.

The tire’s stabilizing effects stem from its ability to distort under load, and from the fact that its adhesion to to the road is always in proportion to the amount of distortion. The distortion does not create the adhesion; it is merely a concurrent effect — but it provides a signal that tells the rider how near is the limit. This is most noticeable in cornering: when subjected to side loads, the tire distorts as it passes through the area where it meets the road, and this distortion causes it to creep off to the side, away from the load and toward the outside of the turn. The creeping should not be confused with a loss of traction, or skidding; it is due entirely to the progressive distortion in the contact area. Tire engineers refer to this creeping as the “slip angle,” but that is just a convenient term applied to an effect that is difficult to describe.

The creep, or slip angle, works for the rider in two ways: first, it makes the bike run wide, to travel in a larger circle than the rider intended, which in turn reduces the cornering load and eases the bike back away from the absolute limit of adhesion; second, the rider can, with experience, judge from the extent of the slip angle how much he is asking of the tires, and how much faster he can go before the limit is reached.

There is a third beneficial effect of the pneumatic tire that adds stability when running in a straight line. If the front wheel is deflected from its straight-on position, the resulting side load and contact area distortion creates a self-aligning torque that will, unless the deflection is too severe, instantly snap the wheel back into line. This selfaligning torque can be felt by the rider during cornering, too, and it is an additional signal to tell him how much he is asking of the tire.

Finally, there is the stabilizing influence of the tire’s unwillingness to run at a camber angle. Lean the tire over to the side and it promptly develops a side thrust in that dlirection — assuming that it is rolling, of course. This means that if the bike is tilted to the side, a thrust in the same direction is developed down at the contact patch, and the bottom of the tire tries to crawl over and force the tire back into an upright position. Obviously then, camber thrust will always try to hold the bike perpendicular to the surface over which it is being run. It is worth mentioning that camber thrust will try to pull the tire up onto bumps in the road, compensating in some degree for the tendency of such bumps to deflect the wheel to the side. The pneumatic tire is, as you will have realized by now, a truly marvelous device — despite its vulnerability to accidental deflations.

Now then, having established to everyone’s satisfaction (we hope) that the pneumatic tire is the answer, even though it admittedly has shortcomings, we can proceed to the more practical considerations of tire construction, and what type is best for which application.

Just as in Dunlop’s original invention, present day tires derive their shape and strength from the layers of cord in their carcasses. And, the arrangement of this cord is extremely important in determining the characteristics of the complete tire — at least as important, in fact, as the rubber compound used in the tread.

Cord in tires is usually arranged in two or more layers, or plies, and these layers are tied to the “bead,” which is that part of the tire that fits against the rim of the wheel. The bead is reinforced with strands of wire, which makes it virtually inextensible and holds the bead in tightly against the rim when the tire is inflated. Were it not for these wire strands, the bead could stretch out and over the rim, and the tire would deflate rather suddenly should that occur. In any case, the bead provides a foundation to which the rest of the tire structure is tied.

The layers of cord lead across from bead to bead at an angle, and this angle has a lot to do with the tire’s ultimate characteristics. The most advantageous strength/ weight ratio is had by leading the cords straight across, at a 90-degree angle to the beads, as in that position they are best situated to resist bursting pressures. Unfortunately, when arranged at that 90-degree angle, they are unable to brace the tread against deformation from cornering, accelerating or braking loads, and a tire with 90-degree cords would feel very squishy to a rider, always oozing off to the side when the bike is banked over.

Zero-angle cord, laid in parallel to the bead, provides precisely the opposite characteristics, and would brace the tread so much that maximum cornering power would be obtained at a very low slip angle — and that would, as a result, leave the rider with a situation uncomfortably like that occurring when using a steel tire. The solution is a compromise. The cords are arranged in criss-cross fashion, running diagonally from bead to bead, and that not only gives adequate strength, but provides a measure of bracing for the tread.

In general, tires made for ordinary road use will have fairly high cord angles, as this makes the carcass soft enough to absorb a lot of shock and most road-riders do not indulge in great feats of cornering speed in any case. Racing tires are more likely to have their cords arranged at angles nearer that impossible zero we discussed before. Such cord angles do reduce “feel” to some extent, but they brace the tread and raise the level of cornering power. Tires made by Dunlop for pure high-speed straightaway work represent an extreme: their cord angle is only about 25-degrees. This is to brace the tread so much that there is no tire expansion at high speeds and the destructive

“standing-wave” that can occur in the over 150-mph range is eliminated. Also, the Dunlop high-speed tires have a bare minimum of rubber laid over the cord. This reduces the amount of rubber in flexure and prevents heat buildup in the carcass. Many people do not realize that a rolling tire gets quite hot. Rubber has a lot of internal friction, and when it is flexed rapidly, as happens when the tire passes around through the contact patch, the friction creates heat that can send tire temperatures soaring. Obviously, the more rapidly a tire rotates, the more frequently flexing occurs at any given point along the tread and, therefore, the more rapidly heat is generated.

Strictly speaking, the only reason for applying rubber up on a tire’s sidewalls is to seal the cord against moisture and keep it from deterioration. That is why tires that have developed cracked sidewalls through age or ozone attack are not safe: moisture may have caused damage to the cord. Apart from this, however, some rubber is required on the sidewalls to guard the cord against random encounters with sharp rocks, etc., and then too, a vigorously-ridden motorcycle will spend some time traveling along fairly high on its sidewalls. For that very obvious reason, the tread is extended up around the sidewalls on motorcycle tires.

The compounding of rubber has a marked effect on tire performance. Broadly speaking, soft rubber provides the best grip and hard grades the best wear, and tread materials are mixed for racing or touring accordingly. In point of fact, the coefficient of friction does not vary much with hardness, so a very hard rubber could be used on a glassy-smooth surface and it would adhere just as well as soft rubber. However, road surfaces are textured, and the soft compounds will sink into the myriad small depressions and thereby offer a kind of “cog-wheel” action, giving a much better grip than would be afforded by pure contact friction.

The most exotic recent devélopment in tire rubber is the “high hysteresis” compound that is now very much a news item in road racing. High hysteresis rubber, or as the British call it, “cling rubber,” is rubber that has a very high internal friction — so much so, that it loses most of the bounce that characterizes ordinary rubber. A ball made of high hysteresis rubber does not bounce much more than one made of putty — although the “cling” rubber is not noticeably softer than the normal variety. Tires made of conventional rubbers do a good job of maintaining contact with the road, but their springiness causes a sort of vibration in the tire contact patch that tends to lift the rubber slightly and reduce the cogwheel effect. Cling rubbers do just as the name implies: the lack of bounciness allows the rubber to cling to the road surface. This type of tire shows the most marked improvement over conventional tires when wet roads are involved. In the wet, cling rubber tires have delivered up to 20percent more grip than the conventional types.

Seldom are gains made without corresponding losses, and that is precisely the case with cling rubber tires. The high internal friction that helps keep these tires in intimate contact with the road also creates a fair amount of heat and adds to rolling resistance, so that tire temperatures go up and absolute top speed will necessarily drop slightly. Even so, they are of inestimable value when running on wet roads and/or when racing. Both Dunlop and Avon produce these tires in both racing and touring versions, and they appear to be well worth having.

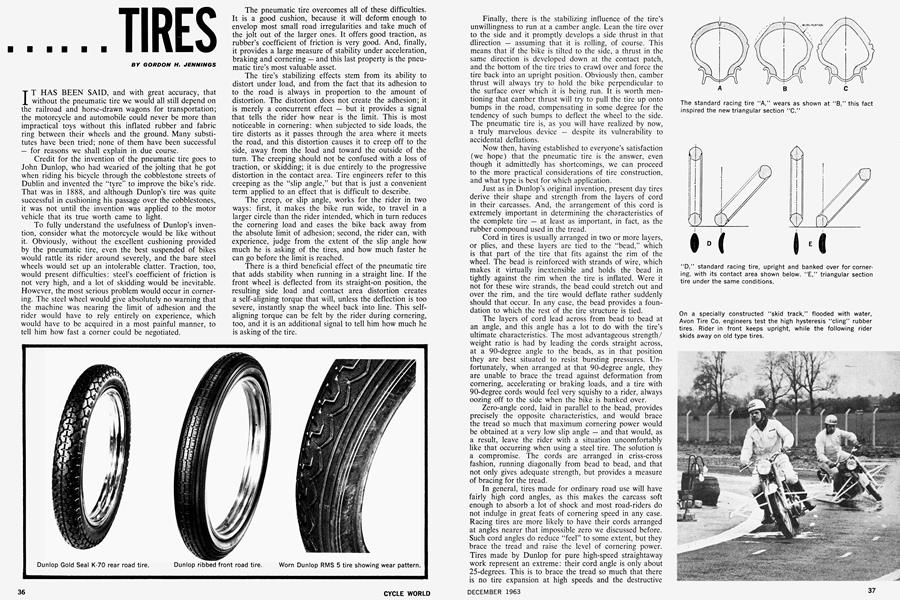

Rivaling high hysteresis rubber in importance is the development, by Dunlop, of the triangular-section tire. Some time ago, it was noticed that tires used in road racing were shaped by wear into a peak; the effects of cornering removing rubber on the sides of the tires. Further, it became apparent that a tire thus worn was somewhat better, with regard to cornering power than when new — and this started a train of thought that has resulted in Dunlop’s new RMT-1 racing tire. The Dunlop design is preshaped, so to speak, with the flats built right into the new tire. This gives a somewhat reduced contact area when the machine is upright, but there is much more rubber in contact when banked over in a corner. As a consequence, tire/ road adhesion is improved up to about 10-percent and cornering speeds rise a corresponding amount. Dunlop’s RMT-1 tire sacrifices some contact area, when the machine is in the upright position, as compared to the conventional pattern, but this is a small price to pay for the greatly improved cornering and in actual tests, lap times have been cut about 8-percent. It goes almost without saying that Dunlop has used high hysteresis rubber in their new tire.

Dunlop’s approach to tread pattern design on their latest tires is a study in the successful meeting of tread design requirements. When a machine is upright, only acceleration and braking loads must be dealt with, and Dunlop’s engineers have made cross-grooves in the tire crown to handle these loads. Maximum traction demands grooves cut across the direction of the load, as this provides pressure edges that press into the textured pavement and increase the tire’s grip. Of course, this implies conflicting requirements for the direction of the grooves for braking and acceleration, and for cornering, and this is in fact the case. Therefore, the grooves up on the sides of the tire should run around its circumference.

Unfortunately, not all braking and accelerating are done with the machine perfectly upright. It is necessary to accelerate fairly vigorously when still banked over and exiting from a turn, and a rider may, on occasion, want to brake while in the turn. To meet these conditions, the grooving on the sides of the Dunlop tire are a series of curves; tight curves next to the center portion of the tread to handle an approximately even mixture of cornering and accelerating loads, and more open curves, presenting more of an edge to the side thrusts of cornering, far around on the side of the tire.

Other tire manufacturers may take a different approach to the solution of these traction problems, but it is possible to see the nature of the problem in the form taken by tire treads. The requirements of which we have spoken are recognized universally.

There is, in addition to the conflict of requirements between braking and acceleration, and cornering, also a difference in the requirements for front and rear tires. The rear tire we have already covered; the front is much the same except that it does not have to transmit accelerating forces. Thus, for the front tire, we need cross grooving almost entirely in the center of the tread, to handle braking loads. Pure cornering thrust can be met by circumferential ribs on the sidewalls. Finally, due to factors of weight distribution, etc., it is usually necessary to fit a tire of a larger section on the rear wheel, as all of the loads are heavier there.

While on the subject of tire patterns, something should be said about wet-surface performance. A perfectly smooth tread will give acceptable, and in some special instances, superior traction on dry pavement, but a little water will upset things entirely. Here, tire grooving is most important. The pressure edges on the tread blocks squeeze the water away so that the tread has a semi-dry contact with the road, and the grooves form a channel to carry off the water. The best tread pattern for running in the rain is one that has many small cuts, called “sipes,” leading off of the main grooves. These sipes offer extra pressure edges and give a good grip in the wet. Again, however, the gain is not without a corresponding loss: cutting the tread in many places tends to reduce its stability, and dry-surface adhesion suffers. And, wear tends to be more rapid as the number of cuts, whether sipes or main grooves, is increased.

Tires made for off-the-road use have a carcass structure much like that of a normal touring tire, but with added strength to withstand the pounding of sharp rocks, stumps and the like. But, of course, they have very specialized tread patterns, with the rubber molded into cleats. These cleats may be round, or square, or even rectangular, and those with rectangular cleats sometimes have the cleats in Vshaped rows across the face of the tire. When mounted with the point of the V toward the front, these cleats present an an edge that resists skidding when the machine is banked over — due to the fact that only one side of the V is in contact with the ground and the machine is sliding out to the side slightly. At first glance, it would appear that the tire should be mounted with the V faced in the opposite direction, but closer examination of the problem will show that what we have said is true. In all honesty, we must admit that the point would have escaped us had an expert rider not mentioned the matter.

In road racing, touring or scrambles, indeed anything but pure highspeed running, the best tire for traction would seem to be the biggest available. However, practical considerations impose limits on tire size. Wegiht is the most serious drawback; a tire is a fairly heavy bit of equipment in any case, and it should be obvious that we should limit weight as much as possible. And, after a certain point is reached, further increases in tire size produce only slight increases in adhesion under any circumstances.

From the standpoint of the private owner, tire size — large or small — will be limited to a very great extent by the wheels on his machine. At any given rim width, there are only a few section sizes that are advisable. Obviously, only 19inch tires can be used on 19-inch wheels. But, tire section sizes and rim widths can be mismatched, too. A tire that is too small in section for the rim on which it is mounted will assume a very poor shape (for cornering) and, as much of the side wall will be forced into a straight line with the rim, flexing of the sidewalls will tend to concentrate into the area adjacent to the bead and rapid deterioration of the sidewall will occur. A tire of too large a section for a rim will be insufficiently braced, and would be easily pushed to the side — making for very poor handling. To reduce the dangers for individuals who may be contemplating a drastic change of tires, we are including a chart showing the popular rim diameters, widths, and the suitable tires for each.

Pure load capacity for tires is set by the size and inflation pressure — with the capacity rising with increases in pressure, up to a point. These maximum values are set by a standards institute, and apply to all makes of tires. Another chart is presented here that gives load capacities, at various inflation pressures.

Retreaded tires can give very acceptable service — as good, when the retreading job has been done properly, as a new tire. But, it is absolutely essential that the tire carcass to which the retread is applied be in good condition. A carcass that is old, or has been “bruised,” is a poor candidate for retreading. And, of course, the success of the retreading depends on the skill of the man doing the retreading job. As in buying new tires, it is wise to pay for quality.

Considering how much the tire does toward supplying good handling, performance, and most important, safety, it is rather surprising how little thought many riders give to those very vital rubber doughnuts. We have seen bikes run on tires totally unsuited to the job they were being asked to do; and we have seen bikes run on tires that were wearing out their umpteenth retread and had serious weatherchecking all over their sidewalls. It is our hope that this article will do something toward reducing misuse and outright carelessness. •

View Full Issue

View Full Issue