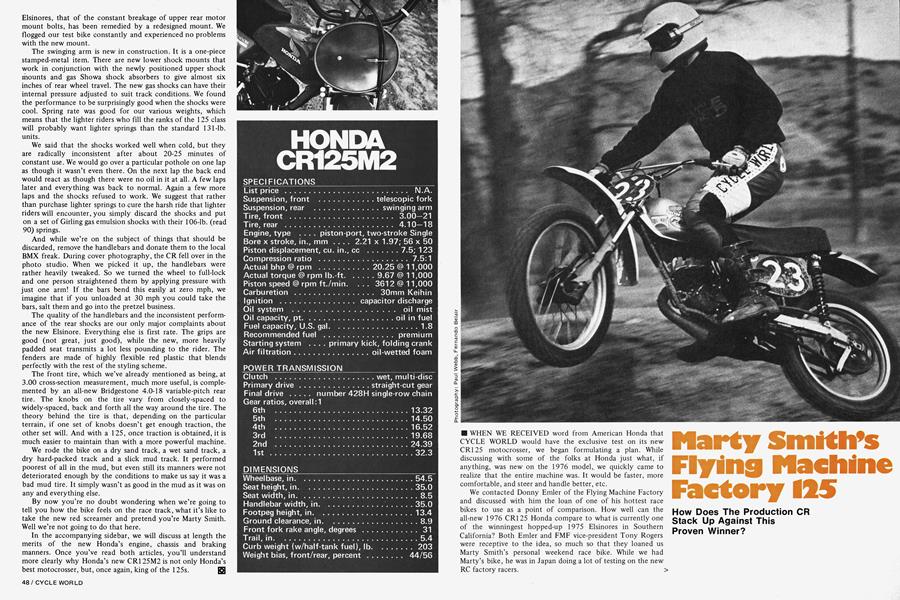

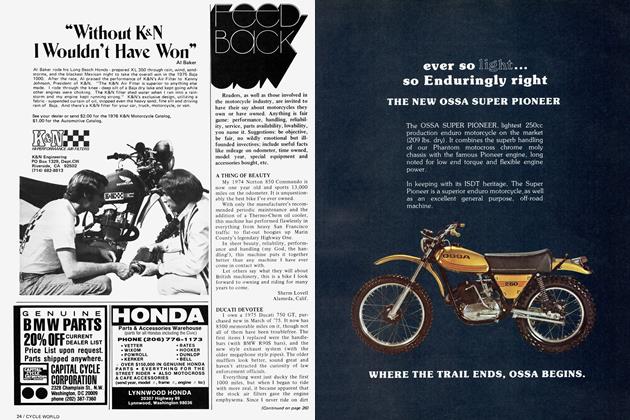

Marty Stmith’s Flyring Machine Factory 125

How Does The Production CR Stack Up Against This Proven Winner?

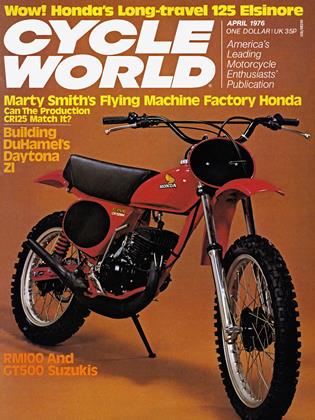

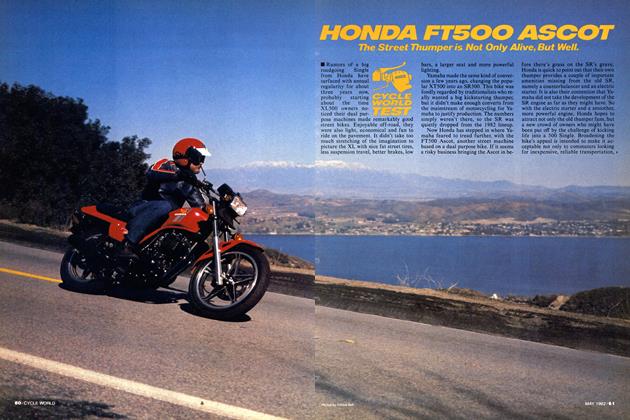

■ WHEN WE RECEIVED word from American Honda that CYCLE WORLD would have the exclusive test on its new CR125 motocrosser, we began formulating a plan. While discussing with some of the folks at Honda just what, if anything, was new on the 1976 model,, we quickly came to realize that the entire machine was. It would be faster, more comfortable, and steer and handle better, etc.

We contacted Donny Emler of the Flying Machine Factory and discussed with him the loan of one of his hottest race bikes to use as a point of comparison. How well can the all-new 1976 CR125 Honda compare to what is currently one of the winningest hopped-up 1975 Elsinores in Southern California? Both Emler and FMF vice-president Tony Rogers were receptive to the idea, so much so that they loaned us Marty Smith’s personal weekend race bike. While we had Marty’s bike, he was in Japan doing a lot of testing on the new RC factory racers.

The engine in Marty’s FMF Honda was freshened with a new piston. The machine was relieved of the previous Sunday’s muck and the air filter was cleaned. Equipped with a new spark plug, it was ready for us to take home.

Before we ever got them out to a race track, the machines underwent one of a number of unofficial CYCLE WORLD tests, i.e. 8 p.m. parking lot drag races. At this point, both engines had only about an hour on them. The FMF bike stomped the production machine. This was an indication of things to come, although the gap would close considerably.

The FMF bike is given its advantage by a number of things, but it is primarily a product of its boost-port cylinder, a 32mm Mikuni, an FMF porcupine head and an FMF CR125 “Pro” pipe. These competition parts work in conjunction with several others to make the dyer run like a scared rabbit and handle far better then a pre-‘76 stocker.

Because of the increased power and the resultant strain on the piston, FMF recommends that a new piston be installed after every six racing hours to keep the power “fresh.” We put ours through about 12 hours of WFO riding under about a dozen different pilots, who abused the heck out of the racer with nary a consequence. All those who rode the FMF bike had nothing but compliments for it. They also had very nice things to say about the handling of the stocker, although they were not as impressed with the power.

However, soon after, the stocker loosened up and began closing the gap on the FMF machine. But with both bikes running at full strength, the FMF bike still had about one to one-and-a-half seconds per lap on the red racer.

Those ‘74 and ‘75 Elsinore owners who rode the potent FMF screamer finally understood why they were getting their doors blown off every Sunday. The difference in power and handling between the Marty Smith FMF racer and other ‘74 and ‘75 Elsies was much greater than that betweeen the FMF and our ‘76 CR. As a matter of fact, with its sturdier forks, slightly reduced trail, higher footpeg position and less sensitive rear brake, the ‘76 Flonda outhandles the ‘75, even when the latter is equipped with the suspension modifications that FMF provides. At least until the stock shocks get hot. Put the FMF’s gas Girlings on the red bike and you can work magic. For a better breakdown of the suspension components and a deeper understanding of how they operate, read the accompanying suspension dyno graphs and explanations. To understand why the two machines differ in acceleration rate, study the engine dyno charts.

Comparing the engine graphs gives us a clue to the performance of the two machines. From 7-9000 rpm the Stocker produces about a horsepower more than the FMF. But at 9000 the older bike takes over and maintains a 1.5-2.0 hp advantage. When the stocker signs off at 11,000 rpm, the FMF bike continues to increase horsepower production for another 500 turns. When shifting, particularly after second gear, the engine rpm drops right back down into the range where the FMF machine is really getting down to business. When you consider that this horsepower advantage is utilized in each of the six gears, and that the FMF machine enjoys a 16-lb. advantage over the new machine, you can see why lap times are lower, in spite of its being at a slight handling disadvantage to the ‘76.

We found the brakes on the Emler-modified bike to be strong up front and touchy in the back. Even with its heavier weight, the stock machine could outbrake the FMF going into corners. The rear brake on the stocker is one of the finest we’ve ever encountered on an MXer. It was difficult to lock up, yet took little pressure to become optimally effective.

What this whole thing boils down to is this: the FMF machine, with the modifications listed at the end of this article, is an absolute rocket compared to the stock 1975 Elsinore on which it is based. Compared to the new and vastly improved 1976 Honda, however, it is merely faster. It does not outhandle it like it does other ‘75s. The point here is that you can either take the machine you now own and invest in FMF > equipment to make a Marty Smith Replica racer, or you can sell what you have, purchase one of the new ‘76 models and then start equipping it with go-fast goodies. We don’t know yet whether the ‘76 machine can be made to run faster than the ‘75 FMF we had. We assume that it can be made to run as fast. But who can tell? When the Donny Emlers of the world get through porting, piping, carbureting and otherwise creating extra power for the new red racer, there’s just no telling how fast it’ll be. E3

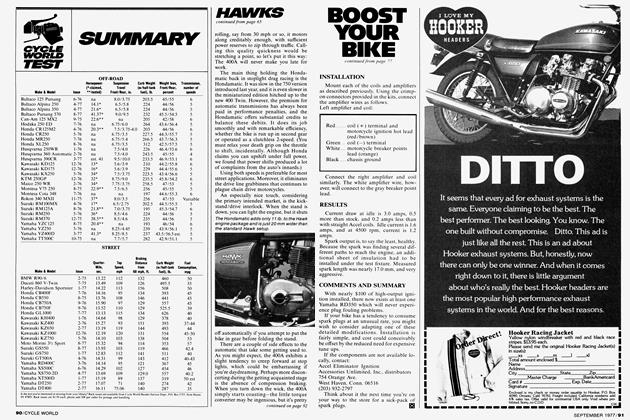

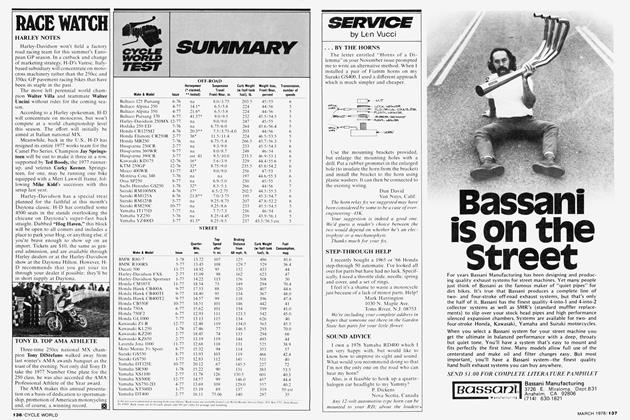

CR125M2

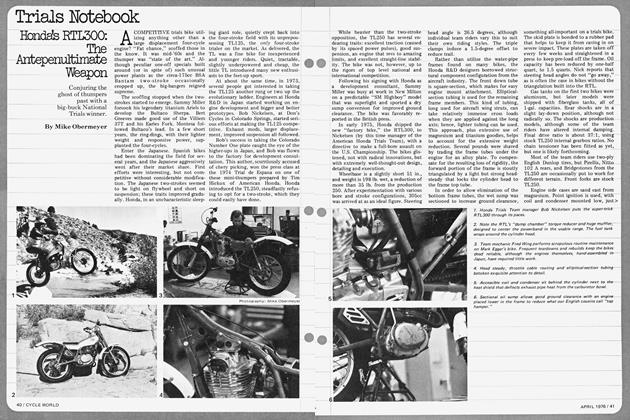

SUSPENSION DYNO TEST FRONT FORKS

Description: Kayaba fork, 35mm stanchion tubes, HD31 5 oil

Fork travel, in.: 7.5 Engagement, in.: 5.8 Spring rate, lb./in.: 28 Compression damping force, lb.: 13 Rebound damping force, lb.: 24 Static seal friction, lb.: 12

Remarks: Honda has radically changed the forks on the CR125 for 1976. Stanchion tube diameter has been increased from 31 to 35mm. By doing this, Honda has gained strength at the expense of increased weight. Travel of these new forks is 0.75 in. greater than that of the forks on last year's CR250, which have the same tube diameter. Damping and spring rates for the CR125's forks are virtually identical to last year’s CR250's. There is slightly too much compression damping, which will tire forearms. Rebound damping is acceptable. Spring rate is high, but it too is acceptable because Honda uses virtually no spring preload.

REAR SHOCKS

Description: Honda CR125gas/oil shock Shock travel, in.: 3.75—4.0 (depending on bumper compression) Wheel travel, in.: 5.75—6.25 (depending on bumper compression) Spring rate, lb./in.: 131 Compression damping force, lb.: 25 Rebound damping force, lb.: 225

Remarks: Gas pressure is adjustable. If bottoming occurs, all that is necessary is an increase in gas pressure. The rebound damping force is exceptionally high for the 131-lb. spring. This is to keep the motorcycle from pitching after the rear wheel encounters holes in the track. On a particularly bumpy track the rider may not have benefit of full wheel travel because the excessive rebound slows the wheel's return to the ground. Spring rate with normal preload for this machine should be approximately 100 lb. Honda has opted for a 131-lb. spring with virtually no preload. The result is a softer initial ride with slightly less tendency to bottom because of a higher resistance in the last inch of shock compression. The shaft guide bearing is sloppy, which may lead to premature seal failure.

Tests performed at Number One Products

FMF125

SUSPENSION DYNO TEST FRONT FORKS

Description: FMF air fork, 10 lb. air pressure, HD315 oil Fork travel, in.: 7.0 Engagement, in.: 3.75 Spring rate, lb./in.: infinitely variable (air pressure + 24-lb. spring) Compression damping force, lb.: 12 Rebound damping force, lb.: 20 Static seal friction, lb.: 18

Remarks: In order to extend travel to 7.0 in., FMF extended the slider and added an oil cooler at the bottom. The stock damper rod is used, but two rebound springs are fitted instead of one. There are two reasons for this. The first is to insure enough fork engagement for safety purposes. The second is that, because the air increases the fork's rate of return, additional cushion is necessary to prevent topping and ultimate destruction of the damper assembly. A better way to control the rate of return damping in this application would be to weld shut the original return damping hole. The rod should then be redrilled with two damping holes, which together should equal the same area as the standard hole. These new damping holes should be spaced 0.5 to 0.75 in. apart. The highest hole should be 0.25 in. below the bottom of the rebound spring. This would allow for a softer return at maximum fork extension, which would in turn place less stress on the upper bushing. As is, compression damping is perfect for hard riding. Rebound is marginally light and there is too much static seal friction. With the exception of needing better fork seals, the forks are too close to being perfect to warrant any modification, unless it were to be done in the interest of greater reliability.

REAR SHOCKS

Description: Girling gas/oil shock Shock travel, in.: 4.5 Wheel travel, in.: 6.5 Spring rate, lb./in.: 106 Compression damping force, lb.: 45 Rebound damping force, lb.: 110

Remarks: Gas and oil are intermixed in this shock. Operating temperature is extremely high, but damping remains consistent. Girling has gone to a higher quality guide bearing for the shaft in order to increase reliability. Considering the mechanical advantage on the FMF/Honda compression damping, rebound damping and spring rate are perfect.