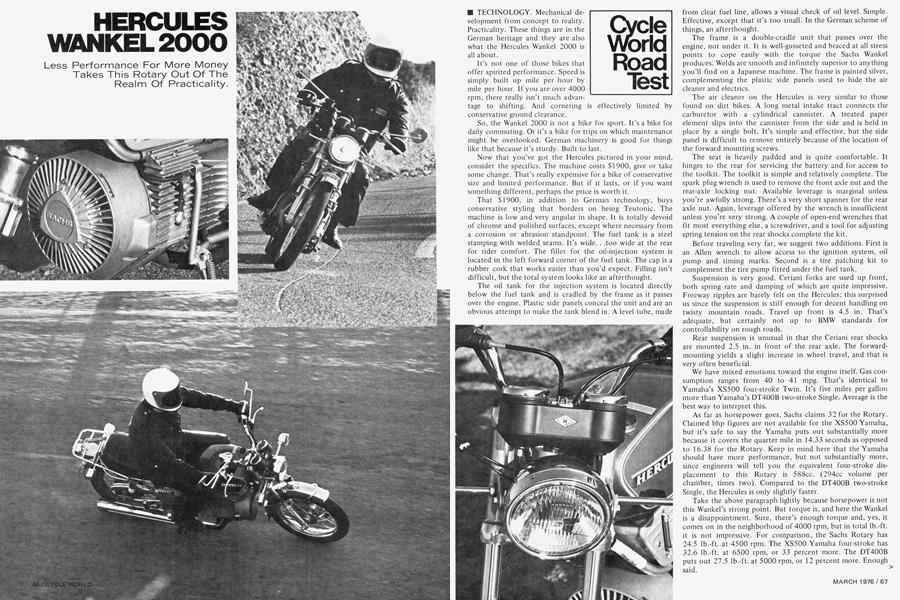

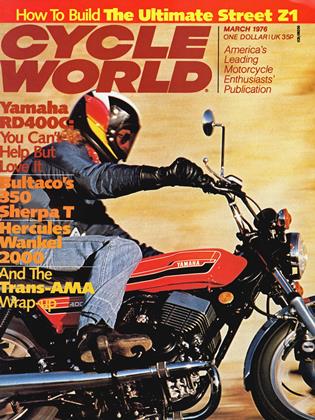

HERCULES WANKEL 2000

Less Performance For More Money Takes This Rotary Out Of The Realm Of Practicality.

Cycle World Road Test

TECHNOLOGY. Mechanical development from concept to reality. Practicality. These things are in the German heritage and they are also what the Hercules Wankel 2000 is all about.

It’s not one of those bikes that offer spirited performance. Speed is simply built up mile per hour by mile per hour. If you are over 4000 rpm, there really isn’t much advantage to shifting. And cornering is effectively limited by conservative ground clearance.

So, the Wankel 2000 is not a bike for sport. It’s a bike for daily commuting. Or it’s a bike for trips on which maintenance might be overlooked. German machinery is good for things like that because it’s sturdy. Built to last.

Now that you’ve got the Hercules pictured in your mind, consider the specifics. The machine costs $1900, give or take some change. That’s really expensive for a bike of conservative size and limited performance. But if it lasts, or if you want something different, perhaps the price is worth it.

That $1900, in addition to German technology, buys conservative styling that borders on being Teutonic. The machine is low and very angular in shape. It is totally devoid of chrome and polished surfaces, except where necessary from a corrosion or abrasion standpoint. The fuel tank is a steel stamping with welded seams. It’s wide. . .too wide at the rear for rider comfort. The filler for the oil-injection system is located in the left forward corner of the fuel tank. The cap is a rubber cork that works easier than you’d expect. Filling isn’t difficult, but the total system looks like an afterthought.

The oil tank for the injection system is located directly below the fuel tank and is cradled by the frame as it passes over the engine. Plastic side panels conceal the unit and are an obvious attempt to make the tank blend in. A level tube, made from clear fuel line, allows a visual check of oil level. Simple. Effective, except that it’s too small. In the German scheme of things, an afterthought.

The frame is a double-cradle unit that passes over the engine, not under it. It is well-gusseted and braced at all stress points to cope easily with the torque the Sachs Wankel produces. Welds are smooth and infinitely superior to anything you’ll find on a Japanese machine. The frame is painted silver, complementing the plastic side panels used to hide the air cleaner and electrics.

The air cleaner on the Hercules is very similar to those found on dirt bikes. A long metal intake tract connects the carburetor with a cylindrical cannister. A treated paper element slips into the cannister from the side and is held in place by a single bolt. It’s simple and effective, but the side panel is difficult to remove entirely because of the location of the forward mounting screws.

The seat is heavily padded and is quite comfortable. It hinges to the rear for servicing the battery and for access to the toolkit. The toolkit is simple and relatively complete. The spark plug wrench is used to remove the front axle nut and the rear-axle locking nut. Available leverage is marginal unless you’re awfully strong. There’s a very short spanner for the rear axle nut. Again, leverage offered by the wrench is insufficient unless you’re very strong. A couple of open-end wrenches that fit most everything else, a screwdriver, and a tool for adjusting spring tension on the rear shocks complete the kit.

Before traveling very far, we suggest two additions. First is an Allen wrench to allow access to the ignition system, oil pump and timing marks. Second is a tire patching kit to complement the tire pump fitted under the fuel tank.

Suspension is very good. Ceriani forks are used up front, both spring rate and damping of which are quite impressive. Freeway ripples are barely felt on the Hercules; this surprised us since the suspension is stiff enough for decent handling on twisty mountain roads. Travel up front is 4.5 in. That’s adequate, but certainly not up to BMW standards for controllability on rough roads.

Rear suspension is unusual in that the Ceriani rear shocks are mounted 2.5 in. in front of the rear axle. The forwardmounting yields a slight increase in wheel travel, and that is very often beneficial.

We have mixed emotions toward the engine itself. Gas consumption ranges from 40 to 41 mpg. That’s identical to Yamaha’s XS500 four-stroke Twin. It’s five miles per gallon more than Yamaha’s DT400B two-stroke Single. Average is the best way to interpret this.

As far as horsepower goes, Sachs claims 32 for the Rotary. Claimed bhp figures are not available for the XS500 Yamaha, but it’s safe to say the Yamaha puts out substantially more because it covers the quarter mile in 14.33 seconds as opposed to 16.38 for the Rotary. Keep in mind here that the Yamaha should have more performance, but not substantially more, since engineers will tell you the equivalent four-stroke displacement to this Rotary is 588cc. (294cc volume per chamber, times two). Compared to the DT400B two-stroke Single, the Hercules is only slightly faster.

Take the above paragraph lightly because horsepower is not this Wankel’s strong point. But torque is, and here the Wankel is a disappointment. Sure, there’s enough torque and, yes, it comes on in the neighborhood of 4000 rpm, but in total lb.-ft. it is not impressive. For comparison, the Sachs Rotary has 24.5 lb.-ft. at 4500 rpm. The XS500 Yamaha four-stroke has 32.6 lb.-ft. at 6500 rpm, or 33 percent more. The DT400B puts out 27.5 lb.-ft. at 5000 rpm, or 12 percent more. Enough said. Now, keeping this in mind, consider the problem of meeting future emission standards. At the present time, the Sachs Rotary has no emission control devices whatsoever. In the future, emission control devices will be necessary, because rotary engines are not “clean” in an uncontrolled state. Current thought on controlling rotary emissions is to fit a catalytic converter that operates in the neighborhood of 2000 degrees F. Now on Mazda cars, this is fine, because on a car you can shield the driver and passengers from the excessive heat of the converter. But what are they going to do on a motorcycle? Where are they going to put a converter to prevent it from burning the rider? It’s a fair question and we are waiting for someone to attempt an answer.

So much for future problems. Let’s consider a present problem. The Sachs Wankel will run on just about any type of gasoline. Same goes for transmission oil. But injection oil must be special. Shell Rotella SX 30 works best but isn’t available in this country, unless you go to the trouble of ordering it special. Suzuki Rotary oil may work, so if you are near a Suzuki dealer when you run low, there is hope. Failing this, any oil will do, but not for long. In 250 miles or so, particularly it you run the engine hard, the sealing elements will char and jam. Loss of compression and difficult starting will result. If you can get the engine started (towing may be necessary) Shell Rotella oil will eventually cure the problem. If the engine will not start, it must be disassembled and cleaned.

Reliability of this Rotary, then, is directly related to the oil used. Use the right oil and it will be reliable. But if by choice or chance this isn’t possible, you’re in for trouble. We know. We had the problem.

From an engineering standpoint, the motor is interesting. It works like Suzuki’s engine in principle and shares the fact that there are few moving parts. The rotary proper is made up of the eccentric shaft, the rotor with apex seals, the stationary gear and the bore the rotor runs in. The eccentric shaft is what transmits the power produced by the rotor to the clutch and six-speed transmission. On the shaft is an offset circular surface that the rotor runs against. It’s called the bulge. The eccentric shaft rotates inside a stationary gear that is fixed to the rotor housing.

The pressure of combustion exerts a downward force on the rotor and forces the rotor directly away from the combustion face. This downward motion causes the eccentric shatt to rotate. The rotor itself revolves in an orbit because the teeth ot the internal rotor gear and stationary gear are meshed. Each time the rotor revolves 120 degrees, the eccentric shaft makes one revolution. The bore shape of a rotary is referred to as a trochoid. The exact shape of the rotor is determined by the dimensions of the trochoid.

The seals on the edges of the triangular rotor are called apex seals and they correspond to piston rings in a piston engine. Like a two-stroke engine, there are ports in the cylinder to allow the passage of intake and exhaust products. Timing is determined solely by the position of the rotor.

The rotor in the Sachs Wankel does not revolve in line with the wheels. Therefore, a set of bevel gears (like in an automotive differential) are necessary to transmit power from the eccentric shaft to the transmission main shaft. The transmission is a six-speed unit taken directly from the 400 Penton dirt bike. The ratios are nice, but because the gears are undercut, neutral cannot be engaged without the rear wheel moving. It’s also difficult to rock the bike enough to get the transmission back to low if it isn’t done while stopping. The shift lever is long and it must be moved farther than we like in order to change gears. Missed shifts, however, are not a problem if you do it right.

The clutch is a seven-disc unit, running in an oil bath, as is common practice. Under most conditions, it works well enough. If you stop for a long period of time in low gear with the clutch in, it will drag. . .in the end enough to make it difficult to keep the engine running (remember you can’t get neutral when stopped).

Riding the Rotary is for the most part pleasant. When it starts, it does so right away, although there is an annoying clang when the engine lights oft. The engine is louder than desirable, although not nearly as annoying as Suzuki’s RE5 in this respect.

If you are cruising through town with little load on the engine, it burbles and the machine surges some. Get on the gas and this disappears.

Gearing is pretty tall, about the same as a CB750 Honda’s. Indicated rpm at 60 mph is only 3750. Not bad. And it pulled up any hill we found in sixth, no problem, at 50-55.

When it comes time to pass, though, a couple of downshifts will be necessary. Even so, performance is not spectacular, just adequate if the driver of the car you’re passing doesn’t stand on it at the same time. If he does, you lose.

On freeways, the Hercules is affected by rain grooves more than most machines. Same for cross winds, in spite of the low center of gravity. Cornering stability is excellent, however. Actually, the low center of gravity and tire profile encourages fast cornering; up to the machines ground clearance limit, it’s really nice both in steering and stability. Going left, the centerstand drags all too soon. It’s even possible to drag it in town if you’re in a hurry to beat a stoplight. Footpegs are rigid and are wide enough to make contact with the ground, as well. We really prefer folding pegs from both safety and clearance standpoint. If it weren’t for the limited ground clearance, handling on the Hercules would far exceed the capabilities of the engine.

The same thing is true of the brakes. A hydraulic disc up > front works well as long as the front brake lever does not bottom against part of the throttle housing (ours did when we took delivery). The rear drum unit is equal to the front in feel and stopping ability.

Electrics are bad. The tach is electric and wanders too much. It also reads about 4000 rpm with the engine off if the ignition switch is turned to the night position. In the night position, the lights remain on at all times. In the daytime position, the headlight remains on except when the machine is in neutral. The horn is not loud enough; and the battery goes dead if the engine does not start quickly.

Switches are worse. They are Italian because the German switches the factory intended to use were all purchased by BMW. Besides being confusing and poorly labeled, you can’t operate the starter button with a heavily gloved hand. You can’t reach the turn signals without removing your hand from the throttle. Sometimes when you hit the turn signal switch, you also hit the engine kill switch. Et cetera.

One final annoyance is the centerstand. For its size, this is the most difficult bike to get up on the stand that we’ve ever encountered. It’s at least as difficult as a poorly designed 750 stand.

So does the Hercules Rotary, or any Rotary for that matter, have a place in motorcycling? As an unusual machine, for sure. As an engineering exercise, for sure. As practical transportation, maybe. But as far as offering superior performance, economy or reliability at competitive prices, no way. 151

SUSPENSION DYNO TEST

FRONT FORKS

Description: Ceriani fork with HD 315 oil Fork travel, in.: 4.25 Spring rate, lb./in.: 42 Compression damping force, lb.: 14 Rebound damping force, lb.: 18 Static seal friction, lb.: 10 Remarks: Compression damping is marginally too heavy. Rebound damping is too light for the 42-lb. spring fitted. The spring is inordinately heavy because it is not preloaded. The result is a choppy ride under most conditions. However, because the spring is not preloaded, the forks react quite well to cracks on roads and freeways that prove annoying on most machines.

REAR SHOCKS

Description: Ceriani shock Shock travel, in.: 2.75 Wheel travel, in.: 4.0 Spring rate, lb./in.: 80/105 progressive Compression damping force, lb.: 38 Rebound damping force, lb.: 105 Remarks: Compression damping is too high and adds to the machine's overall choppy ride. Lowering it to 20 lb. would help a great deal, but such a modification is not possible with average hand tools. Rebound damping is excellent. Stability and handling precision do not suffer from these characteristics. It is unfortunate that the machine does not have sufficient ground clearance to make suspension like this a worthwhile compromise in favor of handling, as opposed to comfort. Tests performed at Number One Products

HERCULES WANKEL 2000

$1900

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsUp Front

March 1976 -

Letters

LettersLetters

March 1976 -

Departments

DepartmentsFeedback

March 1976 -

Features

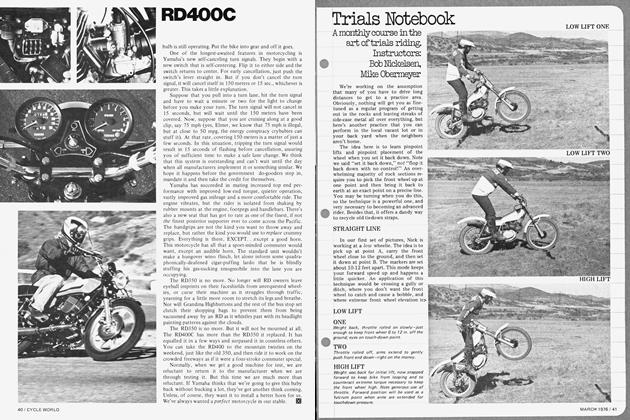

FeaturesTrials Notebook

March 1976 By Bob Nickelsen,, Mike Obermeyer -

Competition

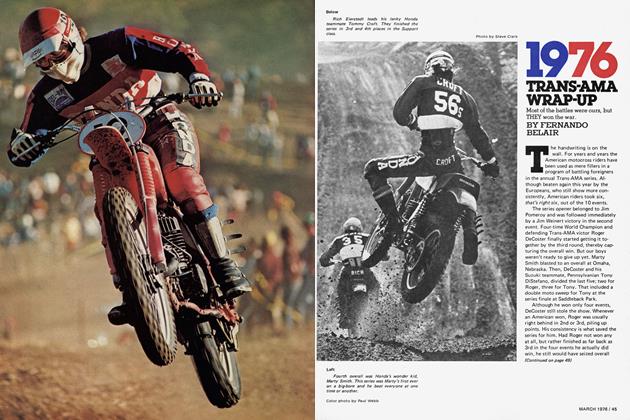

Competition1976 Trans-Ama Wrap-Up

March 1976 By Fernando Belair -

Technical

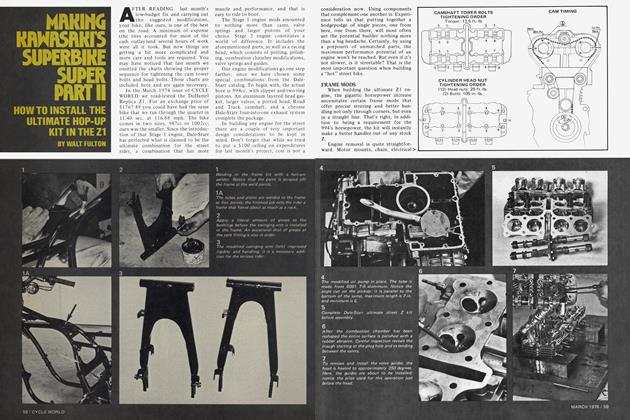

TechnicalMaking Kawasaki's Superbike Super Prrt Ii

March 1976 By Walt Fulton