Rebuilding The World's First Motorcycle

He wants a bike just like the bike that harried good old Gottlieb.

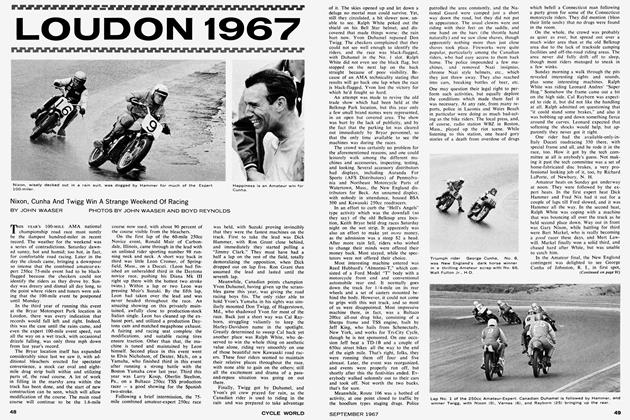

John Waaser

These days the only frontier left is up in space, or so we commonly think. And the only way a man can get his feet wet in the space game is to start with a doctorate in some obscure science, then add a practical knowledge of thermodynamics, properties of materials, and other subjects which many of our readers have probably never even heard of.

Less than a century ago, it was all different. The popular means of transportation was the railroad—a huge, firebreathing, smoke-belching machine that required rails before it could go anywhere. Anyone with dreams of another form of transit was either a visionary or a lunatic, depending on your point of view. And, while stories of space travel and undersea life abounded, they were fiction. The first internal-combustion engines were running just barely before 1860, and men like Lenoir, DeRochas, and Otto—who gave his name to the four-stroke cycle—were the pioneers in engine design.

But engines are not transportation in themselves. The men who built engines then fashioned around them motorcars and bicycles—the Duryeas, the Chevrolets, the Fords—were simply skilled hand workers for the most part, not engineers. The construction of an engine and a car or motorcycle were tasks that could be accomplished by you or me, had we the initiative and the intestinal fortitude. You can well imagine the response of various neighbors to these fools who were trying to blow up the entire block with their infernal contraptions. Can you imagine, then, the dreams, the hopes, the fears, the frustrations, the incredible highs, the unreachable depths of depression of these men, and the ridicule and scorn to which they were subjected by their peers?

One man in Massachusetts wants to share these feelings with Gottlieb Daimler, builder of the world’s first known internal-combustion-powered motorcycle. Ken Williams is a sheet metal worker by trade, and an avid antique collector who has restored several antique bikes. While searching for some information on a Ner-A-Car that he was restoring, he came across the story of Daimler’s first motorcycle. It gnawed away at his insides until he knew that he had to build a replica.

Williams’ empathy with Daimler is such that he even wants his replica to fail the first time he tries to fire it up, like the original did. Like Daimler, he wants to take a 17-mile trip with it, and then put it on blocks, not caring whether it runs again. He has endured skepticism and taunts from his friends, but he fully expects to have that satisfying last laugh. Two other replicas of this machine have been built by the Daimler factory, but neither of them have run. Most of Williams’ friends take one look at the simple engine design and declare that his bike cannot possibly run, either.

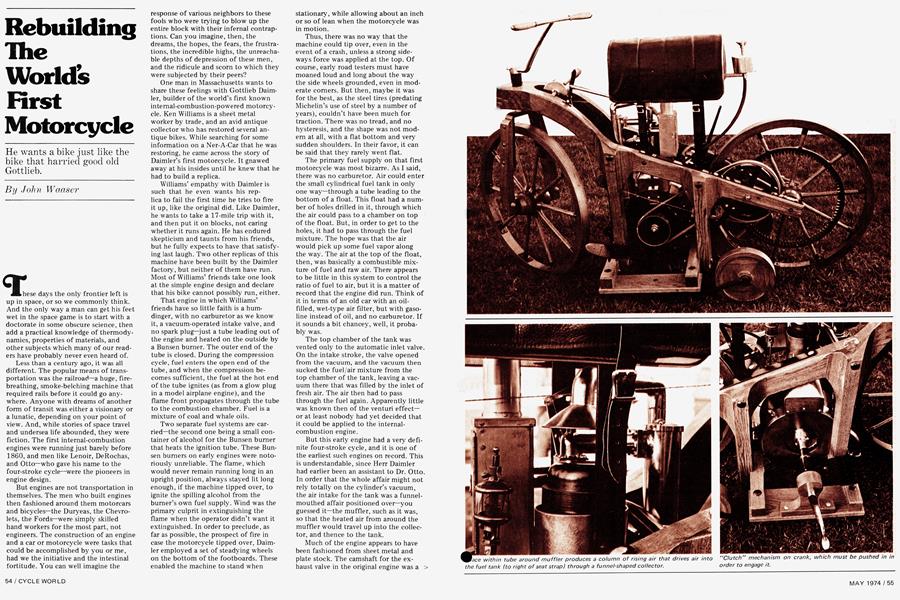

That engine in which Williams’ friends have so little faith is a humdinger, with no carburetor as we know it, a vacuum-operated intake valve, and no spark plug—just a tube leading out of the engine and heated on the outside by a Bunsen burner. The outer end of the tube is closed. During the compression cycle, fuel enters the open end of the tube, and when the compression becomes sufficient, the fuel at the hot end of the tube ignites (as from a glow plug in a model airplane engine), and the flame front propagates through the tube to the combustion chamber. Fuel is a mixture of coal and whale oils.

Two separate fuel systems are carried—the second one being a small container of alcohol for the Bunsen burner that heats the ignition tube. These Bunsen burners on early engines were notoriously unreliable. The flame, which would never remain running long in an upright position, always stayed lit long enough, if the machine tipped over, to ignite the spilling alcohol from the burner’s own fuel supply. Wind was the primary culprit in extinguishing the flame when the operator didn’t want it extinguished. In order to preclude, as far as possible, the prospect of fire in case the motorcycle tipped over, Daimler employed a set of steadying wheels on the bottom of the footboards. These enabled the machine to stand when stationary, while allowing about an inch or so of lean when the motorcycle was in motion.

Thus, there was no way that the machine could tip over, even in the event of a crash, unless a strong sideways force was applied at the top. Of course, early road testers must have moaned loud and long about the way the side wheels grounded, even in moderate corners. But then, maybe it was for the best, as the steel tires (predating Michelin’s use of steel by a number of years), couldn’t have been much for traction. There was no tread, and no hysteresis, and the shape was not modern at all, with a flat bottom and very sudden shoulders. In their favor, it can be said that they rarely went flat.

The primary fuel supply on that first motorcycle was most bizarre. As I said, there was no carburetor. Air could enter the small cylindrical fuel tank in only one way—through a tube leading to the bottom of a float. This float had a number of holes drilled in it, through which the air could pass to a chamber on top of the float. But, in order to get to the holes, it had to pass through the fuel mixture. The hope was that the air would pick up some fuel vapor along the way. The air at the top of the float, then, was basically a combustible mixture of fuel and raw air. There appears to be little in this system to control the ratio of fuel to air, but it is a matter of record that the engine did run. Think of it in terms of an old car with an oilfilled, wet-type air filter, but with gasoline instead of oil, and no carburetor. If it sounds a bit chancey, well, it probably was.

The top chamber of the tank was vented only to the automatic inlet valve. On the intake stroke, the valve opened from the vacuum, and the vacuum then sucked the fuel/air mixture from the top chamber of the tank, leaving a vacuum there that was filled by the inlet of fresh air. The air then had to pass through the fuel again. Apparently little was known then of the venturi effector at least nobody had yet decided that it could be applied to the internalcombustion engine.

But this early engine had a very definite four-stroke cycle, and it is one of the earliest such engines on record. This is understandable, since Herr Daimler had earlier been an assistant to Dr. Otto. In order that the whole affair might not rely totally on the cylinder’s vacuum, the air intake for the tank was a funnelmouthed affair positioned over—you guessed it—the muffler, such as it was, so that the heated air from around the muffler would travel up into the collector, and thence to the tank.

Much of the engine appears to have been fashioned from sheet metal and plate stock. The camshaft for the exhaust valve in the original engine was a > groove, milled right into the side of the flywheel, and included a device which acted as a governor, to control the engine’s speed down hills. When the speed became excessive, centrifugal force moved a ramp to change the elliptical track to a circular one, so the exhaust valve would not open. In that case, there would be no vacuum on the intake stroke, and the engine’s speed would reduce until the cam went back to its normal operation. Luckily, the engine was designed to run at speeds below 1000 rpm. Such a system would seem a bit bogus at more modern speeds, at which the primary fear would be that the cam follower would contact the moving leg of the cam, and cause a bad seizure.

The two previous replicas of this original bike were never designed to run, so the innards didn’t matter. Williams’ bike was designed to be ridden, so for practical reasons, flywheels from an ancient Harley-Davidson were used, and a cam was rigged up to operate the exhaust valve. The exterior of the engine was kept as close to the original as possible, but the interior was made of more practical stuff. In yet another deviation, Williams plans to rig up some sort of timing mechanism to fire the engine from a spark plug the first time around. Only after it has begun running will it revert back to the hot tube ignition.

Approved starting technique consists of lighting the Bunsen burner, waiting for the tube to get hot enough, pushing in on the side-mounted crank to engage it and turning for all you’re worth.

After enough turns to build up a little vacuum, the machine will hopefully start on its own, but then it has to be warmed up until the muffler gets hot enough to drive air into the tank at greater speeds. Ignition timing may be controlled somewhat by varying the length of the tube from the point struck by the Bunsen burner flame, to the open end within the cylinder.

These early engines reportedly backfired quite a bit, in spite of the automatic inlet valve that should have closed the instant an increase in internal pressure occurred from an early firing. Of course, the only place for the fire to go was into the gas tank, which was, incidentally, located directly under the seat. Oh, those hardy pioneers ....

But, if the engine seems primitive, consider the frame—an ungainly concoction of wood. The wheelbase is a mere 40 in., while the wheels themselves are 26 in. in diameter. There is thus only about 14 inches between the front and rear wheels. It does look a mite shortcoupled. There is no suspension system at all, which combines with the short wheelbase to give a bumpy, choppy ride, at best.

The bike has but one brake—on the rear wheel—controlled by a hand lever, which also controls the clutch. Push the handle forward and you apply the brake, while simultaneously disengaging the clutch; pull the handle backward and you engage the clutch, while releasing the brake. It is necessary to remove one hand from the handlebars in order to do this. Such a thing would hardly satisfy Ralph Nader, but then, few motorcycles probably do. There is no throttle: the engine is basically a singlespeed machine, good for about 8 mph on a level road.

The Daimler bike has no rake or trail, and the amount of leverage obtainable from the short handlebars, offset to the rear, is questionable. The combination of the short wheelbase, steering geometry, the single brake (about six inches of friction material rubbing on the outside edge of the rear metal rim), the outrigger wheels, the lack of tires, the weight, the rather copious width, the quality of the available roads and various other factors probably made 8 mph on this machine feel like flat-out on a Vincent Black Shadow. Well, you gotta crawl before you can walk, right?

But, for its time, the machine was actually pretty well advanced, and many people feel that had Daimler stuck with it, he could have advanced the state of the art of motorcycle design by at least a decade. Daimler’s sole purpose for the bike, however, was as a test bed to prove his engine design. Once that objective was accomplished, he scrapped the bike, and went on to four-wheeled vehicles. Nothing is known for certain of the fate of the original, but rumors1 abound that some parts of it made their way to one of the states on the Eastern Seaboard of this country.

One of the more advanced features of this bike at the time of its inception was the drive system, which utilized a leather belt driving a gear arrangement at the rear wheel. The presence of the belt allowed the use of an idler pulley, which could be held in tension by a cable, providing a clutch. “Advanced,” you ask, “when BMW has a shaft, and most other bikes have a chain rear drive?” Ah, but back then, nobody had chains or shafts; a more conventional means of transmitting power to the rear wheel was by a friction drive.

Daimler’s bike had other similarities to modern machines, also. The engine was placed in a manner still approved of by most manufacturers today—amidships. When you consider some of the designs that have come up since—in which the engine rested on the front forks, or off to the side of the rear wheel—it is almost amazing that old Gottlieb hit it right on the first try.

Also, the wheels were of the same size, in an age when fashion had the front wheel of a bicycle much larger than the rear. Even the seating position is very much similar to that on twentiethcentury machines.

Having decided to build a replica of the bike, Williams had to scout up information. Some of Daimler’s original drawings still existed, but many measurements were missing. Surprisingly, 90 percent of the story—or most of what had been written about the bike by various authors—was in the local library, where a nice little old lady helped locate and photostat newpaper clippings. But it took Williams three years to chase down all of the material that he needed.

One year he took his vacation in Germany, where he visited the Daimler factory. Officials were most helpful, showing him as many of the original documents as existed, and allowing him to take measurements and photos of their replica.

Many of the dimensions had to be scaled from various drawings and photographs. Not that there were many photographs of the original machine, but Daimler engineers had made a replica before the second World War from Gottlieb’s original documents. That replica, and the documents from which it was constructed, perished when the plant was destroyed. Luckily, some photos of it remained.

There are some very visible differences between the first replica and the one that Williams has constructed, however. The first replica had a different pattem on the seat than the new one, since Williams decided to utilize the design found on some drawings from Arimler’s period. Another problem is ^rot Daimler changed many of his own drawings as he built the machine, and nobody now alive remembers the details of the original. The handlebar detail is different from the original sketches, as is the belt-drive mechanism.

If you’re intent on building a replica, it must be exactly the way the original was. While the differences listed above wouldn’t matter a damn to a casual observer, they can be a constant fret to the replica builder.

After gathering all of the information that he needed, Williams spent more than a year and a half making the machine. Many, many unexpected problems cropped up at every stage. First of all, there was the early decision to use the Harley-Davidson flywheels and other internal parts with a proven history of running, since Williams was not lachinist, and not a strong engine ïan.

Secondly, he could not bend the wood for the wheels; he didn’t have the facilities to steam it properly, and every time he tried to make a wheel from a single piece of wood, it cracked. So he laminated the wheels from several thinner pieces of wood. As we were wheeling the machine out for photos, we discovered that the metal rims were loose on the wheels, even though they had been a tight press fit when they were assembled. The wood had shrunk.

Everything on the bike had to be hand-fitted. If something didn’t fit when it was finished, it might have to be made all over again from scratch. Often Williams found himself ready to slap a part together even though he knew it wasn’t right. He had to train himself to

áop working when he found himself bdy to do something just for expediency. In fact, training himself to recognize an impulse to do something shoddy was perhaps the hardest part of the whole project, according to Williams.

The only cure he found was to stop working on the bike, and strive to get it completely out of his mind for a few days, so he could tackle it with a renewed sense of purpose.

When the bike is finally finished, has run, and been ridden the 17 miles, and been consigned to a museum, or to a corner of the Williams garage, then what? Why spend thousands of dollars and every spare minute for five years building an essentially useless replica of a machine that the inventor himself tired of almost immediately? Why climb Mount Everest? Why join the space race, or ride the National Circuit? When this Ä|achine has run, Ken Williams will have ^Pumbed the heights and depths of every emotion known to mankind.

That, to him, is reason enough. IS