MONOCOQUE

Is This The Road Racing Frame Of The Future?

GEORGE MARTIN

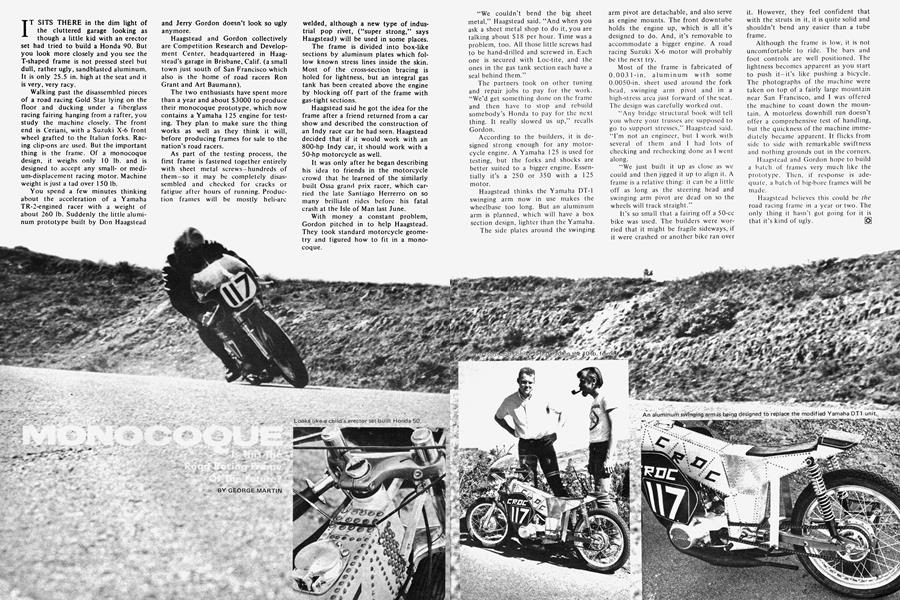

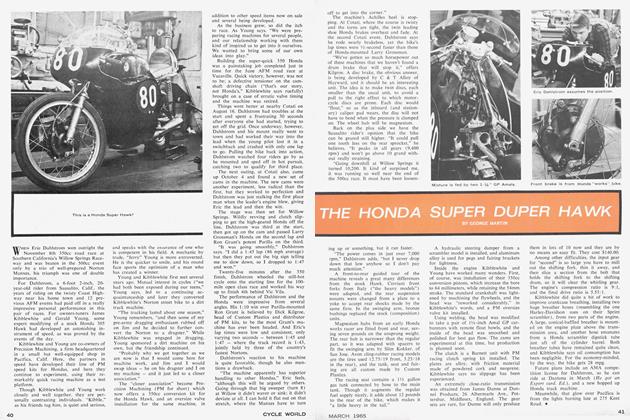

IT SITS THERE in the dim light of the cluttered garage looking as though a little kid with an erector set had tried to build a Honda 90. But you look more closely and you see the T-shaped frame is not pressed steel but dull, rather ugly, sandblasted aluminum. It is only 25.5 in. high at the seat and it is very, very racy.

Walking past the disassembled pieces of a road racing Gold Star lying on the floor and ducking under a fiberglass racing fairing hanging from a rafter, you study the machine closely. The front end is Ceriani, with a Suzuki X-6 front wheel grafted to the Italian forks. Racing clip-ons are used. But the important thing is the frame. Of a monocoque design, it weighs only 10 lb. and is designed to accept any smallor medium-displacement racing motor. Machine weight is just a tad over 150 lb.

You spend a few minutes thinking about the acceleration of a Yamaha TR-2-engined racer with a weight of about 260 lb. Suddenly the little aluminum prototype built by Don Haagstead and Jerry Gordon doesn’t look so ugly anymore.

Haagstead and Gordon collectively are Competition Research and Development Center, headquartered in Haagstead’s garage in Brisbane, Calif, (a small town just south of San Francisco which also is the home of road racers Ron Grant and Art Baumann).

The two enthusiasts have spent more than a year and about $3000 to produce their monocoque prototype, which now contains a Yamaha 125 engine for testing. They plan to make sure the thing works as well as they think it will, before producing frames for sale to the nation’s road racers.

As part of the testing process, the first frame is fastened together entirely with sheet metal screws-hundreds of them-so it may be completely disassembled and checked for cracks or fatigue after hours of running. Production frames will be mostly heli-arc welded, although a new type of industrial pop rivet, (“super strong,” says Haagstead) will be used in some places.

The frame is divided into box-like sections by aluminum plates which follow known stress lines inside the skin. Most of the cross-section bracing is holed for lightness, but an integral gas tank has been created above the engine by blocking off part of the frame with gas-tight sections.

Haagstead said he got the idea for the frame after a friend returned from a car show and described the construction of an Indy race car he had seen. Haagstead decided that if it would work with an 800-hp Indy car, it should work with a 50-hp motorcycle as well.

It was only after he began describing his idea to friends in the motorcycle crowd that he learned of the similarly built Ossa grand prix racer, which carried the late Santiago Herrerro on so many brilliant rides before his fatal crash at the Isle of Man last June.

With money a constant problem, Gordon pitched in to help Haagstead. They took standard motorcycle geometry and figured how to fit in a monocoque.

“We couldn’t bend the big sheet metal,” Haagstead said. “And when you ask a sheet metal shop to do it, you are talking about $18 per hour. Time was a problem, too. All those little screws had to be hand-drilled and screwed in. Each one is secured with Loc-tite, and the ones in the gas tank section each have a seal behind them.”

The partners took on other tuning and repair jobs to pay for the work. “We’d get something done on the frame and then have to stop and rebuild somebody's Honda to pay for the next thing. It really slowed us up,” recalls Gordon.

According to the builders, it is designed strong enough for any motorcycle engine. A Yamaha 125 is used for testing, but the forks and shocks are better suited to a bigger engine. Essentially it’s a 250 or 350 with a 125 motor.

Haagstead thinks the Yamaha DT-1 swinging arm now in use makes the wheelbase too long. But an aluminum arm is planned, which will have a box section design, lighter than the Yamaha.

The side plates around the swinging arm pivot are detachable, and also serve as engine mounts. The front downtube holds the engine up, which is all it’s designed to do. And, it’s removable to accommodate a bigger engine. A road racing Suzuki X-6 motor will probably be the next try.

Most of the frame is fabricated of 0.003 1-in. aluminum with some 0.0050-in. sheet used around the fork head, swinging arm pivot and in a high-stress area just forward of the seat. The design was carefully worked out.

“Any bridge structural book will tell you where your trusses are supposed to go to support stresses.’’ Haagstead said. “I'm not an engineer, bul 1 work with several of them and I had lots of checking and rechecking done as I went along,

“We just built it up as close as we could and then jigged it up to align it. A frame is a relative thing: it can be a little off as long as the steering head and swinging arm pivot are dead on so the wheels will track straight.”

It’s so small that a fairing off a 50-cc bike was used. The builders were worried that it might be fragile sideways, if it were crashed or another bike ran over it. However, they feel confident that with the struts in it, it is quite solid and shouldn’t bend any easier than a tube frame.

Although the frame is low, it is not uncomfortable to ride. The bars and foot controls are well positioned. The lightness becomes apparent as you start to push itit’s like pushing a bicycle. The photographs of the machine were taken on top of a fairly large mountain near San Francisco, and I was offered the machine to coast down the mountain. A motorless downhill run doesn’t offer a comprehensive test ot handling, but the quickness of the machine immediately became apparent. It flicks from side to side with remarkable swiftness and nothing grounds out in the corners.

Haagstead and Gordon hope to build a batch of frames very much like the prototype. Then, if response is adequate, a batch of big-bore frames will be made.

Haagstead believes this could be the road racing frame in a year or two. The only thing it hasn’t got going for it is that it’s kind of ugly.

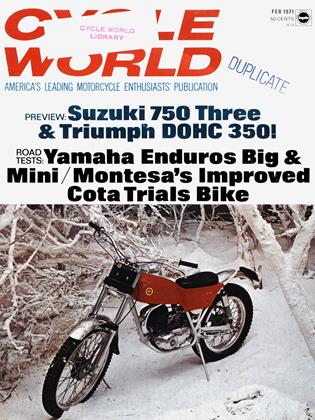

View Full Issue

View Full Issue

More From This Issue

-

Departments

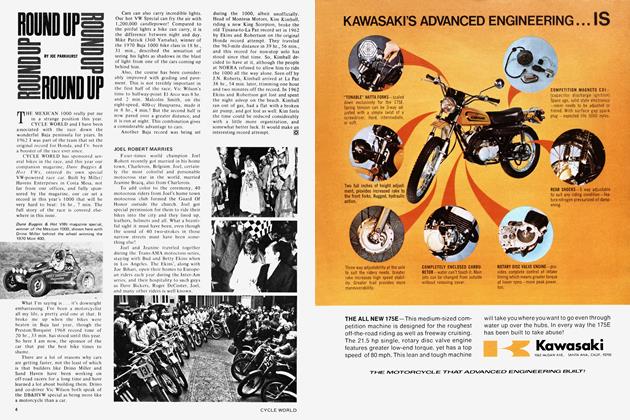

DepartmentsRound Up

February 1971 By Joe Parkhurst -

Letters

LettersLetters

February 1971 -

Departments

DepartmentsThe Service Department

February 1971 By Jody Nicholas -

Departments

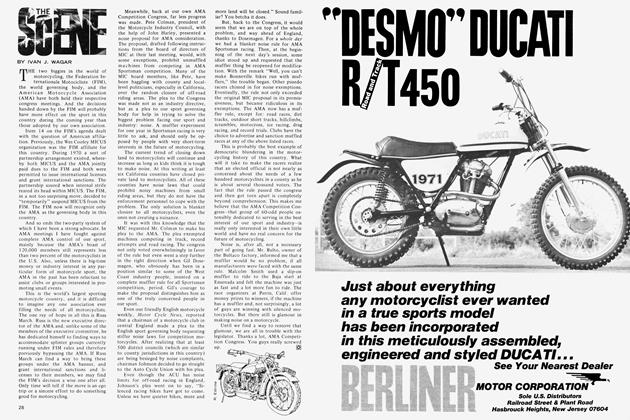

DepartmentsThe Scene

February 1971 By Ivan J. Wagar -

Competition

CompetitionThe Mexican 1000

February 1971 By Ivan J. Wagar -

Special Preview Features

Special Preview FeaturesThe New Bsa/triumph 350

February 1971 By Dan Hunt