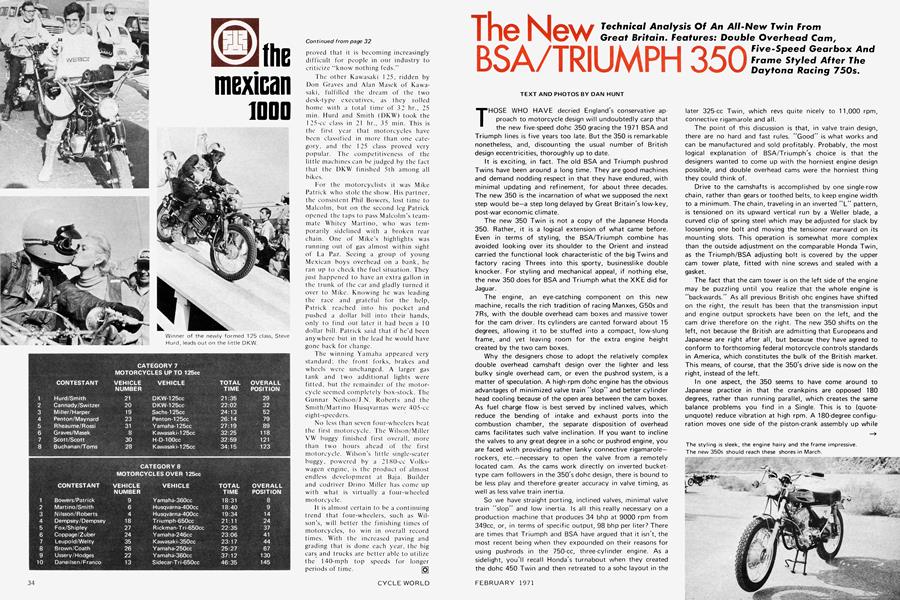

The New BSA/TRIUMPH 350

Technical Analysis Of An All-New Twin From Great Britain. Features: Double Overhead Cam, Five-Speed Gearbox And Frame Styled After The Daytona Racing 750s.

DAN HUNT

THOSE WHO HAVE decried England's conservative approach to motorcycle design will undoubtedly carp that the new five-speed dohc 350 gracing the 1971 BSA and Triumph lines is five years too late. But the 350 is remarkable nonetheless, and, discounting the usual number of British design eccentricities, thoroughly up to date.

It is exciting, in fact. The old BSA and Triumph pushrod Twins have been around a long time. They are good machines and demand nodding respect in that they have endured, with minimal updating and refinement, for about three decades. The new 350 is the incarnation of what we supposed the next step would be—a step long delayed by Great Britain's low-key, post-war economic climate.

The new 350 Twin is not a copy of the Japanese Honda 350. Rather, it is a logical extension of what came before. Even in terms of styling, the BSA/Triumph combine has avoided looking over its shoulder to the Orient and instead carried the functional look characteristic of the big Twins and factory racing Threes into this sporty, businesslike double knocker. For styling and mechanical appeal, if nothing else, the new 350 does for BSA and Triumph what the XKE did for Jaguar.

The engine, an eye-catching component on this new machine, recalls the rich tradition of racing Manxes, G50sand 7Rs, with the double overhead cam boxes and massive tower for the cam driver. Its cylinders are canted forward about 15 degrees, allowing it to be stuffed into a compact, low-slung frame, and yet leaving room for the extra engine height created by the two cam boxes.

Why the designers chose to adopt the relatively complex double overhead camshaft design over the lighter and less bulky single overhead cam, or even the pushrod system, is a matter of speculation. A high-rpm dohc engine has the obvious advantages of minimized valve train "slop" and better cylinder head cooling because of the open area between the cam boxes. As fuel charge flow is best served by inclined valves, which reduce the bending of intake and exhaust ports into the combustion chamber, the separate disposition of overhead cams facilitates such valve inclination. If you want to incline the valves to any great degree in a sohc or pushrod engine, you are faced with providing rather lanky connective rigamarole— rockers, etc.—necessary to open the valve from a remotely located cam. As the cams work directly on inverted buckettype cam followers in the 350's dohc design, there is bound to be less play and therefore greater accuracy in valve timing, as well as less valve train inertia.

So we have straight porting, inclined valves, minimal valve train "slop" and low inertia. Is all this really necessary on a production machine that produces 34 bhp at 9000 rpm from 349cc, or, in terms of specific output, 98 bhp per liter? There are times that Triumph and BSA have argued that it isn't, the most recent being when they expounded on their reasons for using pushrods in the 750-cc, three-cylinder engine. As a sidelight, you'll recall Honda's turnabout when they created the dohc 450 Twin and then retreated to a sohc layout in the later 325-cc Twin, which revs quite nicely to 11,000 rpm, connective rigamarole and all.

The point of this discussion is that, in valve train design, there are no hard and fast rules. "Good" is what works and can be manufactured and sold profitably. Probably, the most logical explanation of BSA/Triumph's choice is that the designers wanted to come up with the horniest engine design possible, and double overhead cams were the horniest thing they could think of.

Drive to the camshafts is accomplished by one single-row chain, rather than gears or toothed belts, to keep engine width to a minimum. The chain, traveling in an inverted "L" pattern, is tensioned on its upward vertical run by a Weller blade, a curved clip of spring steel which may be adjusted for slack by loosening one bolt and moving the tensioner rearward on its mounting slots. This operation is somewhat more complex than the outside adjustment on the comparable Honda Twin, as the Triumph/BSA adjusting bolt is covered by the upper cam tower plate, fitted with nine screws and sealed with a gasket.

The fact that the cam tower is on the left side of the engine may be puzzling until you realize that the whole engine is "backwards." As all previous British ohc engines have shifted on the right, the result has been that the transmission input and engine output sprockets have been on the left, and the cam drive therefore on the right. The new 350 shifts on the left, not because the British are admitting that Europeans and Japanese are right after all, but because they have agreed to conform to forthcoming federal motorcycle controls standards in America, which constitutes the bulk of the British market. This means, of course, that the 350's drive side is now on the right, instead of the left.

In one aspect, the 350 seems to have come around to Japanese practice in that the crankpins are opposed 180 degrees, rather than running parallel, which creates the same balance problems you find in a Single. This is to (quoteunquote) reduce vibration at high rpm. A 180-degree configuration moves one side of the piston-crank assembly up while the other half is moving down, thereby eliminating primary imbalance. But, in a Twin, a 180-degree disposition of crankpins creates a rocking couple, which also may be a source of vibration and stress. Honda's solution to the problem was to add flywheels and support bearings, using the extra engine width created to run the cam drive chain in the cavity between the cylinder barrels of its Twins.

BSA/Triumph's answer is to keep the crankshaft as short as possible by the use of an outside cam drive tower, and slightly smaller bore (Honda's 325-cc Twin is 65 by 50.6mm, while the new Triumph 349-cc Twin is 63 by 56mm). Naturally, moving the pistons, and thus the crankthrows, closer together will diminish the effect of the rocking couple as well as make the crankshaft more rigid by virtue of its shortness. This hopefully precludes the need for extra bearing surfaces, and thus only the two ends of the Triumph 350's crankshaft are supported by ball and roller bearings.

It is probably for this reason that the designers chose to retain the traditional British method of splitting the crankcase vertically. Had they needed extra bearing surfaces, they probably would have gone to horizontally split cases which lend themselves quite well in production to the provision of extra inboard bearing supports. Still, it is hard to argue in favor of vertically split crankcases, particularly with an in-unit transmission, as the horizontally split engine has historically proven itself more oil tight and more easily serviced.

A double-gear pump lubricates the shell-type big ends and also scavenges the dry sump. Oil to the bearings runs first through a large capacity filter with replaceable element. To lubricate the valve gear, the designers have chosen an outside oil line, which is a valid alternative to running a feeder duct through the cylinder barrels, even though it seems somewhat archaic.

The transmission/clutch assembly resembles that of the smooth-shifting "C" series 500 Triumphs, although it now has five speeds instead of four, and is in "mirror" image to its predecessors, having the clutch on the right and the shifting lever on the left. Otherwise, it seems quite the familiar mainshaft/layshaft arrangement, with a horizontal selector plate moving the gears back and forth on their shafts by means of shifting forks. The kick starter is, glory be, on the left side, cranking through the gearbox to turn the engine. A 0.375-in. duplex chain transmits power from the engine to a multi-disc, shock-cushioned wet plate clutch, linked to the mainshaft. Yet another single-row chain links the engine driveshaft with an optional electric starter, nestled on top of the cases behind the cylinder barrel.

A Lucas 110-watt alternator, mounted on the crankshaft drive side, provides current for ignition and lighting. The points are driven off the front cam at the right end. Drive for the tachometer is taken off the crankshaft on the timing side. Near that point, removal of a conically shaped top, which doubles as a pressure relief valve, will expose an oil filter for easy cleaning.

Appearance of so new a British engine overshadows the frame it is carried in, and the rolling gear, both of which are significant improvements in themselves. The frame resembles very closely the triangulated "space" frames in which the potent BSA and Triumph Threes were mounted for running on the AMA road racing circuits last year. If it lives up to its promises, the new 350 should be one of the finest handling production motorcycles ever manufactured in Great Britain. The manufacturers of that country, if conservative in other matters, are unequaled in the design of motorcycle racing chassis.

(Continued on page 96)

Continued from page 37

Basic frame configuration of the 350 is a full double loop, with an important addition. From mid-frame, near the swinging arm pivot, two triangulating members run closely parallel to the cylinders and over the engine to the steering head; this creates a compact, rigid engine bay, and reduces the possibility of mid-frame flex.

Suspension and rolling gear, all-new, and shared with the entire BSA and Triumph lines, should do much to complement the chassis. The internal spring front forks have lightweight alloy sliders and offer two-way hydraulic dampening with 6.75-in. travel. The sliders and the new aluminum conical front and rear brake hubs should do much to reduce unsprung weight, allowing the wheels to more closely follow undulations in the road. At front, the brake is an 8-in. double leading shoe unit, with each shoe adjustable by "snail" cams. The 7-in. rear brake consists of one leading and one trailing shoe operated by a floating cam.

We had a chance to sample these suspension units and brakes on some of the larger BSA and Triumph models, and found that they work quite well.

Other than the horsepower figures, the manufacturers have released no "teasers" in the form of performance claims. It's just as well, as the announced gearing, cranked into a slipstick along with the announced peak rpm figure, gives usan ample prediction of top speed performance that should be accurate to within 5 mph. The claimed performance is 34 bhp at 9000 rpm. With a 6.39 overall ratio the top gear rpm is 870 at 10 mph. If the machine will pull to peak rpm in top gear, which it should with 34 bhp, it will run between 98 and 103 mph flat out. Quarter-mile acceleration runs should yield trap speeds in the neighborhood of 80 to 85 mph from a standing start. This speculation, of course, is contingent on how correctly the designers have geared the machine. If they have, then we may presume that the 350, as delivered, is in a relatively mild state of tune. This thought would be borne out by the throat size of the two Amal Concentric carburetors fitted to the machine—a modest 26mm each.

The definitive figures will come to light when the 350 undergoes the rigors of a CYCLE WORLD road test. It should be exciting.

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

February 1971 By Joe Parkhurst -

Letters

LettersLetters

February 1971 -

Departments

DepartmentsThe Service Department

February 1971 By Jody Nicholas -

Departments

DepartmentsThe Scene

February 1971 By Ivan J. Wagar -

Competition

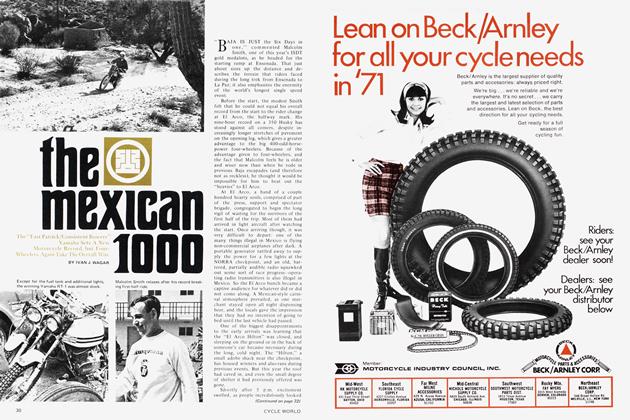

CompetitionThe Mexican 1000

February 1971 By Ivan J. Wagar -

Features

FeaturesMo-Ski-Tow

February 1971 By Gilles Mallet