THE SERVICE DEPARTMENT

JODY NICHOLAS

H-D RAPIDO HOP-UP

TO KIT OR NOT

I was wondering if you could set me straight. I own a 1970 Kawasaki 350-cc Big Horn scrambler. I’d like to put one of those “muscle kits” in it to raise the standard 33 hp to 45 hp. This kit includes a new head and cylinder and a new piston and expansion chamber. The motorcycle will be used both on and off the road. Some friends of mine have a Honda SL 350 and did something similar to increase their horsepower. They have done so without affecting the reliability of the bike. The question I’d like to know is this: will such a kit (some manufacturers call them “GYT kits”) reduce the possibility of my owning a trouble free bike? If so, to what degree?

Ed Mazur Haddonfield, N.J.

Any time you change the engine of a motor vehicle for increased performance, there is a better chance that you will experience trouble with it. By installing a “high-performance” kit, you are asking the engine to deliver more power than in stock tune, and overall flexibility and reliability will suffer.

In order to increase the power of an engine, more gas must be burned at a higher rpm. The engine must also be somewhat richer to preclude overheating and possibly seizing the piston, which may lead to spark plug fouling at low speeds.

As the engine must turn more rpm in developing additional power, wear is also increased to a marked degree, not to mention the additional strain put on the big-end and crankshaft bearings by the increased compression ratio.

If you are serious about racing the bike and don’t mind the expense of maintaining it in a high state of tune, by all means install the kit. However, if you want many miles of troublefree riding with good low and mid-range power and minimum upkeep, leave it stock.

PLUGS AND JETTING

I’ve followed “Service” for several years with interest and thought you might be able to answer a question which has been puzzling me for some time.

I’ve raced two-stroke motorcycles for several years and have yet to receive a satisfactory answer to a rather basic question. When tuning a high speed engine, small changes in spark plug heat range and alterations of air/fuel mixture through minor jetting changes seem to have the same result. Could you compare the effect of these two adjustments?

Also, what is the design difference in spark plugs which makes one hot and another cold?

Al Abbott Los Angeles, Calif.

You are correct in saying that both changes in spark plug heat range and fuel/air mixture produce about the same results, but for different reasons.

By fitting a smaller main jet, you are cutting down on the amount of fuel the engine can receive through the carburetor. However, the amount of air is unchanged, and a smaller jet will cause a leaner mixture and will consequently make the engine run hotter.

(Continued on page 28)

Continued from page 26

A hotter spark plug will do essentially the same thing: make the engine run hotter. A hot spark plug has a longer insulator than a cold one, which tends to keep heat produced by the combustion process near the spark plug tip to help burn off excess carbon deposits.

A cold plug, on the other hand, has a much shorter insulator and therefore transfers heat away from itself rapidly. This heat travels to the cylinder head and is dispelled into the airstream flowing over the head through the cooling fins.

Modern motorcycle engines, with their high compression ratios and high power outputs, require colder spark plugs than the engines commonly in use a few years ago.

It is generally a good idea touse the coldest spark plug possible that doesn’t foul readily, combined with the largest main jet that provides smooth running and good power. If these conditions are both met, the possibilities of an engine seizure are greatly reduced.

KAWA OSCILLATION CURED

I fought the oscillation problem on my ’69 Mach III for 2500 miles and was either going to solve it or swap it. I think I’ve got it licked, and since so many owners of the Mach III are having this problem, you might pass along my solution.

In addition to all the things you mentioned in your answer to Kenneth Wiedenhoeft’s letter, I had even tried moving forward on the saddle, but it still had the fierce “wiggles. ’’ The Kawasaki service dept, may not approve of my method, but I sure as hell don’t approve of their sending over their monster-machine with suspension designed for a 110-pounder. Here is what I did:

1. Tightened steering head bearings.

2. Checked swinging arm for tightness.

3. Checked wheel alignment. At this point, with everything spot-on, it still oscillated at 70 and above.

I decided to see if I could discover if anything on the road would start the oscillation. And, while recovering from a 75 mph saddle-messing lock-to-lock speed wobble, I thought back . . . I hit a bump!

4. 1 removed the fork caps and discovered a set of springs strong enough to close the shutter of a camera. 1 stiffened these at the cost of 60 cents: 40 cents for 40-weight oil and 20 cents for four washers, two for each side. If you replace the oil with 40-weight, and add two washers on each side you get a quicker return and a much more confident rider. I would also recommend that the rear shocks be placed on the middle position of the three-way adjustment.

(Continued on page 30)

Continued from page 28

The washers are steel, one inch in diameter with a 3/8-in. hole. The hole must be there or it will interfere with the telescopic action. In other words, don’t shim it up with solid shims. Use six ounces of oil carefully measured in each leg, set the washers on top of the springs, tighten the fork caps, and give it a try.

Kenneth also mentioned in his letter that he tried braking and relaxing his grip when the oscillations began. Relaxing the grip allows the oscillations to increase, and braking will also increase the oscillations if the front brake is applied. If this happens again, I recommend shutting off the throttle and pretending that each arm is a rod of steel. Keep off the brakes and off the fanny. In a speed-wobble situation, your arms can function as a damper. Don’t wrestle it, but be firm.

John Chick Tulsa, Okla.

Thank you for the valuable tips, John. I’m certain that your letter will be of help to many of our readers with similar problems.

SPORTSTER HOP-UP

I am now serving in Viet Nam with the Marine Corps. I buy your magazine every time I see one in the PX. I have a 1967 XLCH at home, and I would like to build it. I have been told KR flywheels will drop right in. If so, can you tell me where I could get a set of these, or if they can still be ordered? If such flywheels work, could you give me the parts number for the wheels and the best year to buy. I have also been told that large bore cylinders and heads can be gotten. I do not wish to bore my stock cylinders. I would also like to know to what extent I can raise the compression. Could I go as far as 11.5:1 or would this be too much? Any help you can give me in this will be greatly appreciated.

Roger Luhman FPO San Francisco, Calif.

Although the KR flywheels can be used in the Sportster, the swap is not recommended. The KR has the same stroke (3 11/16 in.) as the Sportster and features a larger-diameter crankpin using 1 /4-in. diameter rollers at the big-end. These rollers allow somewhat higher rpm before they start to slide, but the KR connecting rods are not as strong as the standard Sportster units.

(Continued on page 32)

Continued from page 30

The main reason for not using the KR flywheels is that they are just too light for the additional engine size. They provide a little more initial acceleration, but they also make the machine vibrate more and cut down on top-end pulling ability.

Jerry Branch, noted racing tuner and engine builder, of Branch Flowmetrics, recommends the 1/4-in. oversize cylinders and pistons manufactured by Dytch Sales and a compression ratio of no higher than 9.5:1 for street running. The heads and crankcases must be machined out to accept the larger bore cylinders, and a complete cylinder head re-work and enlarged carburetor should be a part of the installation. See the article on Jerry Branch in the next issue for the full story.

SPRINT VALVES

I own a 1969 H-D 350 Sprint. I bought it from a dealer with 600 miles on it. Within 200 miles I had to put in an intake valve. The dealer told me to hold the revs down to 7500 and not to downshift too early. I followed his advice and put in an exhaust valve in another 300 miles. The valves are hitting the piston. The new valve does not have 100 miles on it, and it sounds like it will go soon. This is starting to get expensive. Any help would be appreciated.

Gary Die mi g Danbury, Iowa

Your problem evidently lies in the piston. The early 1969 H-D Sprint models were delivered to dealers with a piston not sufficiently fly-cut in the valve pocket area to allow proper piston-to-valve clearance. Later models had the additional clearance required for a margin of safety in case of slight overrewing or a missed shift.

Have your dealer install a new piston or have the existing piston fly-cut at a machine shop in the valve areas. The removal of .005 in. to .007 in. should prove enough to preclude further trouble and still leave enough material in the piston crown.

Another problem that the Sprint of that vintage suffered from was “valve tightening.” The clearance between the rocker arm and the valve lessened as the machine was run, making it necessary to check the valve clearances more often than the owner’s manual recommends and to re-set them to the factory’s recommendations. [Ö]

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

September 1970 By Joe Parkhurst -

Letters

LettersLetters

September 1970 -

Departments

DepartmentsThe Scene

September 1970 By Ivan J. Wagar -

Special Feature

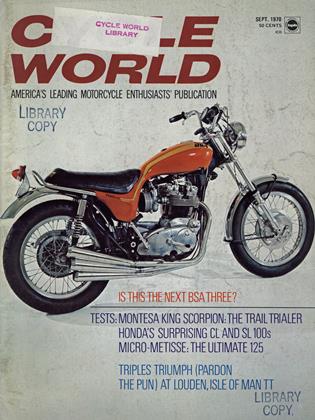

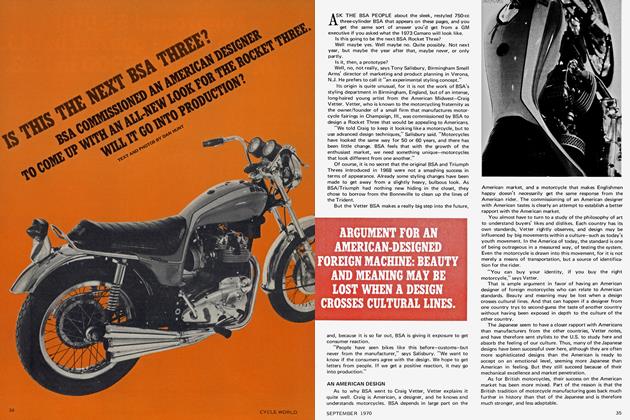

Special FeatureIs This the Next Bsa Three?

September 1970 By Dan Hunt -

Features

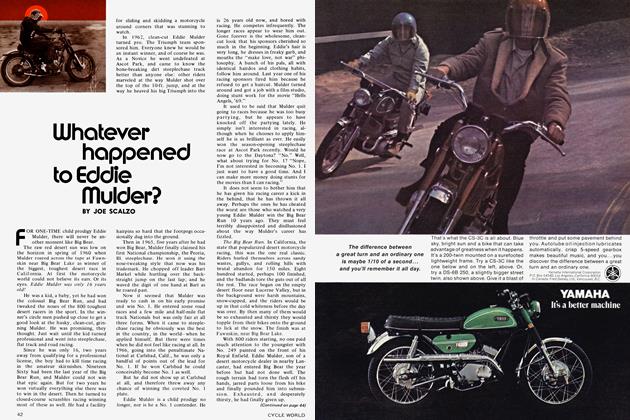

FeaturesWhatever Happened To Eddie Mulder?

September 1970 By Joe Scalzo -

Competition

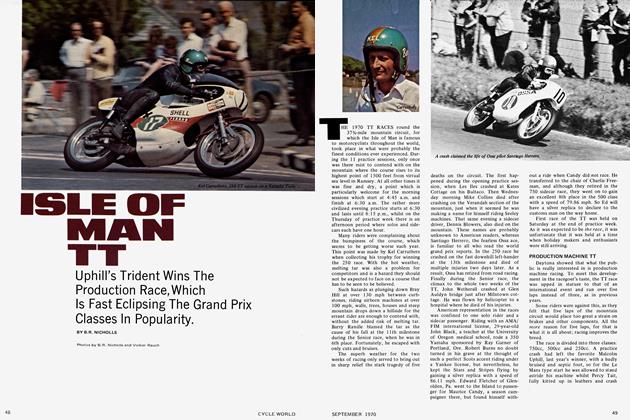

CompetitionIsle of Man Tt

September 1970 By B.R. Nicholls