WE SLAKE 500

From the Old Master of Gas Flow Comes this Grand Prix Contender

DAVID DIXON

ALTHOUGH IT never actually reached beyond the chatting stage, and a series of semi-stimulating articles in the British motorcycling press, the British Lottery World Beater unwittingly achieved success. It sparked the new Weslake twin-cylinder racing engine.

After a lifetime designing, tuning and modifying automotive engines, Harry Weslake, his imagination fired by the Lottery Racer idea, submitted a design. It was thrown out, so he shelved the plan. But the seed had been sown, and it required no great persuasion for him to resurrect the idea in 1967 when he was approached by an affluent retired London motorcycle agent, Ray Creek of Reads’ of Leytonstone. He offered to jointly finance the building of a 500-cc grand prix engine with Weslake.

It had one important difference from the Lottery idea. The Read-Weslake engine was to be a commercial proposition, available (at a hefty price) for anyone to buy, and sufficiently simple in design for a rider to maintain at a race track away from special tools and equipment.

Himself a motorcyclist at Brooklands between 1923 and 1927, before developing the Le Mans-winning Bentleys of the late 1920s, Harry Weslake was aware of the basic requirements. An acknowledged expert on volumetric efficiency-gas flow-he had helped Joe Craig with Norton racing cylinder head design from 1948 until Norton withdrew from racing six years later.

Futhermore, Weslake, now 71, already had built two experimental engines of under 500-cc piston displacement. One was a 375-cc twin-cylinder unit for research by Shell into highspeed lubricants. This powerplant produced 59.5 bhp and ran continuously at 12,000 rpm, with bursts up to 13,800 rpm without bother. Bore and stroke of this engine were 68.5 and 50.8 mm, respectively.

A second unit, to provide data for the Gurney-Weslake Formula I V-12 threeliter engine, was completed. A 500-cc water-cooled Twin with bore and stroke of 72.8 by 60 mm, this unit is reputed to have delivered 80 bhp at approximately 12,000 rpm. It had fuel injection, transistorized ignition, four valves per cylinder, driven by twin overhead camshafts, and titanium connecting rods.

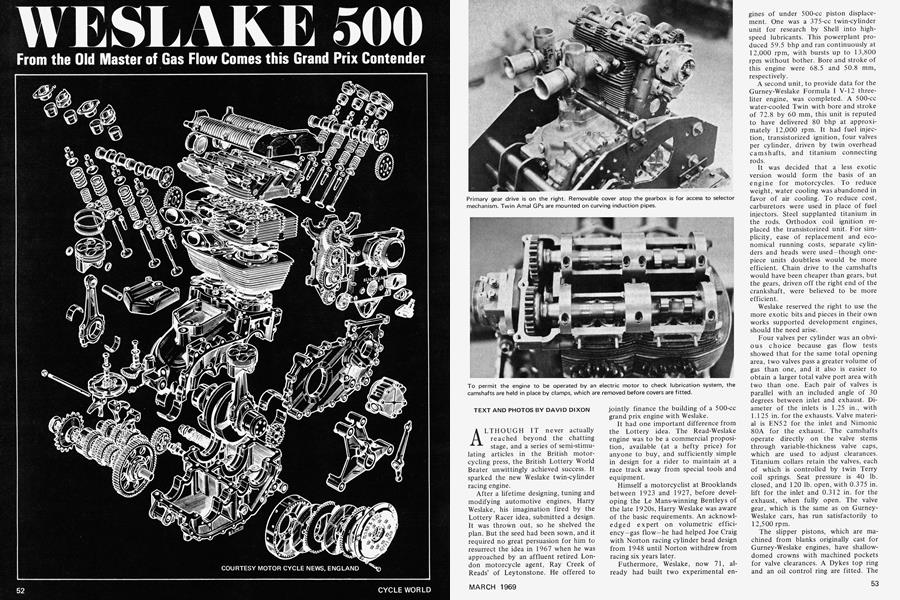

It was decided that a less exotic version would form the basis of an engine for motorcycles. To reduce weight, water cooling was abandoned in favor of air cooling. To reduce cost, carburetors were used in place of fuel injectors. Steel supplanted titanium in the rods. Orthodox coil ignition replaced the transistorized unit. For simplicity, ease of replacement and economical running costs, separate cylinders and heads were used—though onepiece units doubtless would be more efficient. Chain drive to the camshafts would have been cheaper than gears, but the gears, driven off the right end of the crankshaft, were believed to be more efficient.

Weslake reserved the right to use the more exotic bits and pieces in their own works supported development engines, should the need arise.

Four valves per cylinder was an obvious choice because gas flow tests showed that for the same total opening area, two valves pass a greater volume of gas than one, and it also is easier to obtain a larger total valve port area with two than one. Each pair of valves is parallel with an included angle of 30 degrees between inlet and exhaust. Diameter of the inlets is 1.25 in., with 1.125 in. for the exhausts. Valve material is EN52 for the inlet and Nimonic 80A for the exhaust. The camshafts operate directly on the valve stems through variable-thickness valve caps, which are used to adjust clearances. Titanium collars retain the valves, each of which is controlled by twin Terry coil springs. Seat pressure is 40 lb. closed, and 120 lb. open, with 0.375 in. lift for the inlet and 0.312 in. for the exhaust, when fully open. The valve gear, which is the same as on GurneyWeslake cars, has run satisfactorily to 12,500 rpm.

The slipper pistons, which are machined from blanks originally cast for Gurney-Weslake engines, have shallowdomed crowns with machined pockets for valve clearances. A Dykes top ring and an oil control ring are fitted. The piston pin runs in a phospher bronze bush in the connecting rod eye. Compression ratio, at time of writing, is 12.5:1.

The two Amal Grand Prix 1.375-in. diameter carburetors are splayed slightly outward and are horizontally mounted on detachable light alloy stubs which curve downward to match the inlet ports. Encouraging results have been obtained from experiments with cheaper, lighter Concentrics, but, until power is at least on a par obtained from GPs, Concentrics will not be used.

Lucas 12-V coil ignition is used, with twin coils and twin contact-breaker assemblies, driven off the ohc gear train, supplying spark to a single 10-mm plug in each cylinder. The tachometer also is driven off the camshaft gears.

To reduce piston speed at the target 11,000 rpm of the new unit, a grossly oversquare 75.5 by 58.8 mm bore-tostroke ratio was chosen, with a 360-degree crankshaft throw. A 180-degree layout has been designed and its advantage, if any, will be explored later.

By the use of magnesium alloy for the crankcase, sump, timing-gear cover and cam box castings, weight has been kept to a commendable 112 lb., complete with five-speed in-unit gearbox. This compares with 132 lb. for a Manx Norton.

By inclining the light-alloy cylinders (with cast-in liners) forward at 15 degrees from vertical, the center of gravity is kept as low as is feasible with this layout, and weight is transferred forward on to the front wheel. The overall height of 17.75 in. is 5 in. less than a Manx Norton, and width is a mere 14.125 in., which will allow frame builders aim for a low, narrow frontal area.

Automotive practice is seen in the horizontally-split crankcase and gearbox, in which the castings split across the bearing housings. Unusual for a racing motorcycle engine, but standard automotive practice, three massive 2.375-in. diameter by 1.1-in. wide plain bearings are used to support the crankshaft. Of 1.625-in. diameter and 0.7-in. wide, plain lead-indium metal bearings are used for the big ends.

As BSA-Triumph engineers discovered with the new three-cylinder engine, high-speed oil circulation materially assists engine cooling. Weslake already had found this from experience with racing car engines. Thus the dry-sump Twin circulates 1 gal. of mineral oil at 75 psi at an estimated rate of 3.5 gal. per minute through a double acting gear pump below the timing chest. Two filters in the sump are used. Under laboratory testbed conditions, an oil cooler has not been found necessary, but track testing may indicate otherwise. The only lubrication problem encountered, too much crankcase pressure, has been overcome by fitting a timed breather on the left side.

Drive to the five-speed gearbox is by straight-cut spur gears from the righthand end of the crankshaft and running in oil in a separate compartment. Primary reduction is 2.5:1. The mainshaft is supported at both ends by double-row ball bearings, while ball and needle roller bearings support the layshaft. The clutch and final drive sprocket are carried on opposite ends of the mainshaft, the clutch on the right and sprocket on the left. Borg and Beck, who specialize in automotive clutches, designed and supplied a 6-in. diameter unit that weighs 5.5 lb., and employs two friction plates operated hydraulically by a diaphragm. The clutch runs dry outside the primary-drive case.

With the private owner and his maintenance problems in mind, the gear selector assembly is mounted on top of the pinion cluster. Access is through a lid on top of the gearbox casting. Room has been left in the box to add pinions for a sixth ratio, should the need arise.

At the time of writing, bench testing is in final stages. Power is 62.5 bhp between 10,250 and 10,750, with useful output starting around 6500 rpm. Harry Weslake has said, perhaps rashly, that the engine will not be track tested until it develops “at least 70 bhp.” However, his 32-year-old stepson, technical director Mike Daniel, is satisfied that a true 65 bhp will be sufficient.

At any rate, time is no longer with Weslake in the experimental establishment on the southern English coasf. Harry rather optimistically promised the first engines for last March! In his enthusiasm, he overlooked his breadand-butter business, the two dozen projects upon which his 40 staff members were engaged. These ranged from single motorcycle engines to eight-liter military diesels. Incidentally, one Weslake speciality is the conversion of gasoline engines to run on any fuel. “As we, and Reads’, are financing the motorcycle project ourselves, we must look after our own interests first,” Harry explains. “We can only afford one man working full time on the project. He is helped by others when time permits, though in recent months two or three men have been working almost continuously on the project.”

By the time this report reaches CYCLE WORLD readers, the first engine will be track testing in a Rickman Metisse frame, and the first batch of 30 production engines will be completed in a new establishment specially built for the purpose a few miles from the experimental shop. The second engine almost certainly will go to Tom Arter, the veteran who sponsors Peter Wilhams, who had Reynolds build him a new frame last fall.

Outspoken double world champion Phil Read has offered his services, free of charge (unprecedented for a man in his position!) to help develop the machine, provided this is done through Weslake, and not through the Rickmans and Tom Kirby. Read believes that neither Kirby nor the Rickman brothers have sufficient experience for developing an entirely untried engine and frame. In this controversial opinion, Read has a surprising amount of support among the more knowledgeable racing fraternity, for the Metisse racing frame has so far failed to fulfill its early promise. With Yamaha out of grand prix racing, leaving Read unemployed, he is by far the most suitable man, perhaps the only one, who can bring the Weslake to race winning pitch. The engine has the potential.