The Lynton

B.R. NICHOLLS

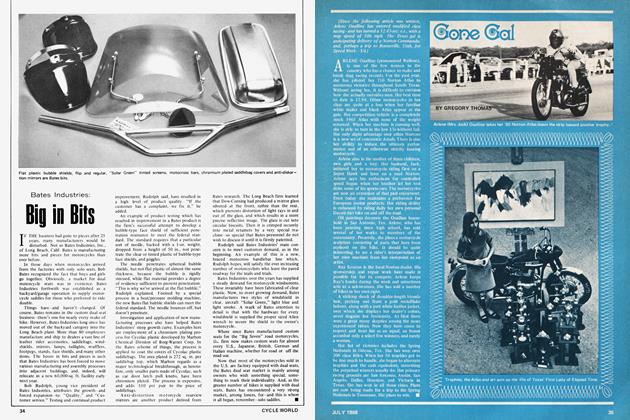

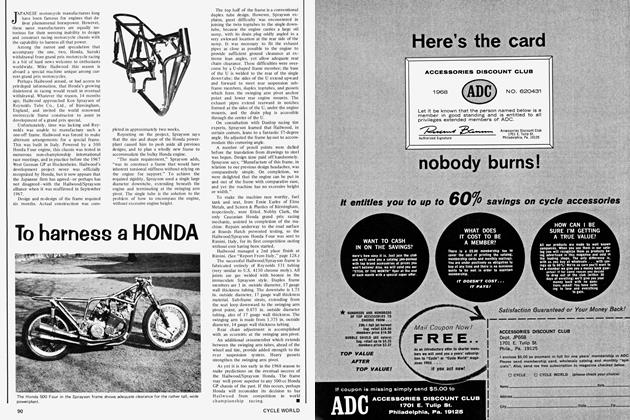

THE DEVELOPING trend in motorcycle racing is toward use of automobile powerplants. Until now, it has been the sidecar people who have made use of automobile engines; a car engine in a motorcycle frame hasn’t been tried for road racing. Drag racing, yes-as witness the Michigan Madman with his 5.3-liter Chevrolet powered two-wheeler-but road racing, no, until now.

Heretofore, automobile engines have seemed much too cumbersome to be of immediate value to the solo road racing rider. And prior efforts along this line aren’t worthy of more than passing mention.

Colin Lyster had the idea to use half a 1000-cc Cosworth Formula II engine in a motorcycle chassis. Then Ford appeared on the scene with a demand for a 3-liter Cosworth V-8 Formula 1 engine. Thus Lyster’s Cosworth halved was put aside and never carried through to reality.

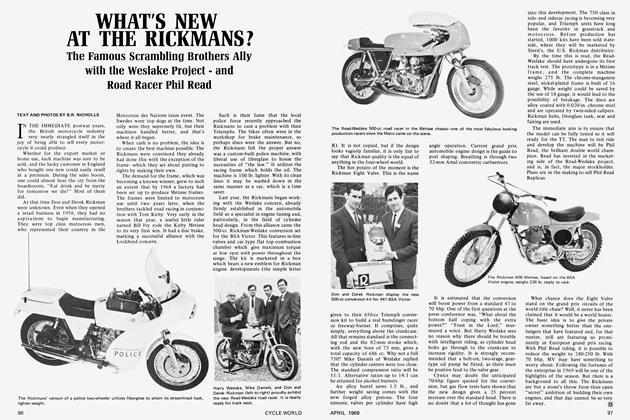

Lyster, a racer of some ability in past years, and an early contributor to CYCLE WORLD, was determined to give his idea a try. In November of 1967, Lyster teamed with Paul Brothers to form Lynton Racing, object of which was to build and market 500-ec Twin engines for grand prix racing. December and January were devoted to preparation of working drawings for a special dohe cylinder head, with four valves per cylinder, to be fitted to one half of a 1000-cc Hillman Imp Four.

Machine work and assembly were springtime projects. On assembly, some problems were encountered, but these have been overcome. A complete engine has been built and bench tested with satisfactory results.

At this writing, the half-imp was scheduled to make its debut in the racing world at Hockenheim, West Germany.

To a purist, the Lynton engine appears all wrong for a motorcycle, but the builders should experience little difficulty in deriving 60 bhp from their creation. If the 60 bhp is forthcoming, the powerplant should be very competitive in solo competition and in sidecar class racing.

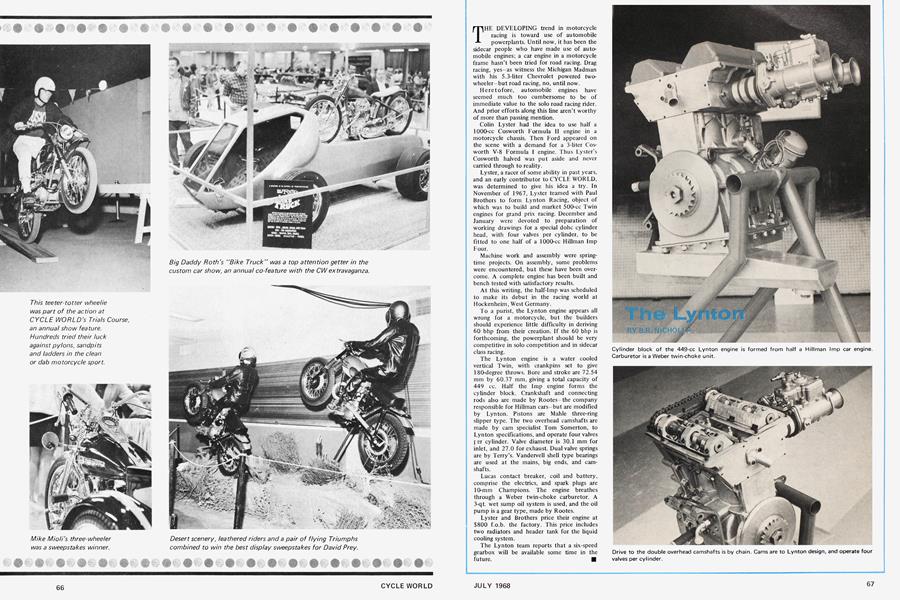

The Lynton engine is a water cooled vertical Twin, with crankpins set to give 180-degree throws. Bore and stroke are 72.54 mm by 60.37 mm, giving a total capacity of 449 cc. Half the Imp engine forms tire cylinder block. Crankshaft and connecting rods also are made by Rootesthe company responsible for Hillman cars-but are modified by Lynton. Pistons are Mahle three-ring slipper type. The two overhead camshafts are made by cam specialist Tom Somerton, to Lynton specifications, and operate four valves fer cylinder. Valve diameter is 30.1 mm for inlet, and 27.0 for exhaust. Dual valve springs are by Terry’s. Vandervell shell type bearings are used at the mains, big ends, and camshafts.

Lucas contact breaker, coil and battery, comprise the electrics, and spark plugs are 10-mm Champions. The engine breathes through a Weber twin-choke carburetor. A 3-qt. wet sump oil system is used, and the oil pump is a gear type, made by Rootes.

Lyster and Brothers price their engine at $800 f.o.b. the factory. This price includes two radiators and header tank for the liquid cooling system.

The Lynton team reports that a six-speed gearbox will be available some time in the future. ■