Big in Bits

Bates Industries

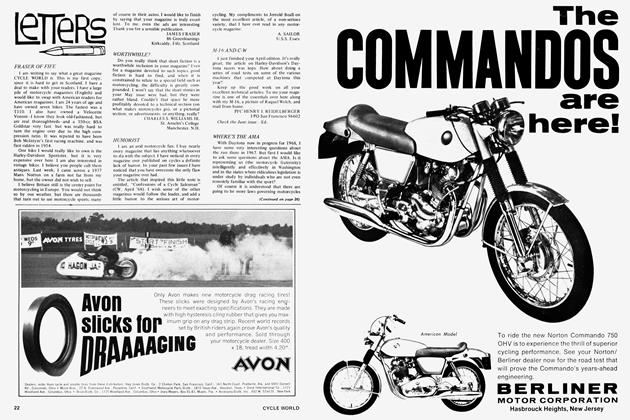

IF THE business had gone to pieces after 25 years, many manufacturers would be disturbed. Not so Bates Industries, Inc., of Long Beach, Calif. Bates is manufacturing more bits and pieces for motorcycles than ever before.

In those days when motorcycles arrived from the factories with only solo seats, Bob Bates recognized the fact that boys and girls go together. Obviously, a market for dual motorcycle seats was in existence. Bates Industries forthwith was established as a backyard/garage operation to supply motorcycle saddles for those who preferred to ride double.

Things have-and haven’t changed. Of course, Bates remains in the custom dual seat business-there’s one for nearly every make of bike. However, Bates Industries long since has moved out of the backyard category into the Long Beach plant. More than 80 employees manufacture and ship to dealers a vast line of leather rider accessories, saddlebags, windshields, mirrors, lamps, taillights, mufflers, footpegs, stands, face shields, and many other items. The boom in bits and pieces is such that Bates Industries has been forced to move various manufacturing and assembly processes into adjacent buildings, and, indeed, will relocate in a new 60,000-sq. ft. facility early next year.

Bob Rudolph, young vice president of Bates Industries, attributes the growth and forced expansion-to: “Quality,” and “Customer service.” Testing and continual product improvement, Rudolph said, have resulted in a high level of product quality. “If the customer has a complaint, we fix it,” he added.

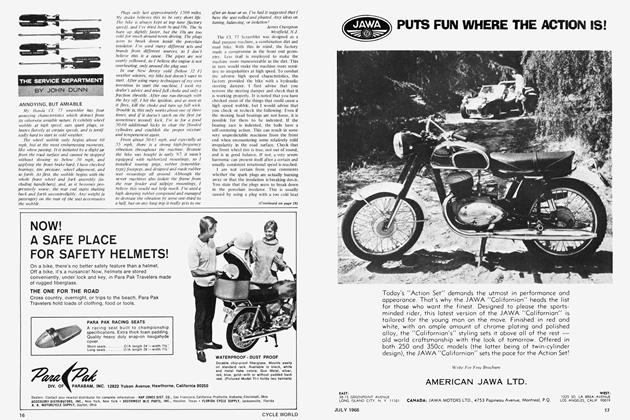

An example of product testing which has resulted in improvement in a Bates product is the firm’s successful attempt to develop a bubble-type face shield of sufficient penetration resistance to meet the federal standard. The standard requires that a particular sort of needle, backed with a 1-oz. weight, dropped from a height of 50 in., not penetrate the clear or tinted plastic of bubble-type face shields, and goggles.

The needle penetrates spherical bubble shields, but not flat plastic of almost the same thickness, because the bubble is rigidly stressed, while flat material provides a degree of resiliency sufficient to prevent penetration. “This is why we’ve arrived at the flat bubble,” Rudolph explained. Formed by a special process in a heat/pressure molding machine, the new Bates flat bubble shields can meet the federal standard. The needle bounces off, but doesn’t penetrate.

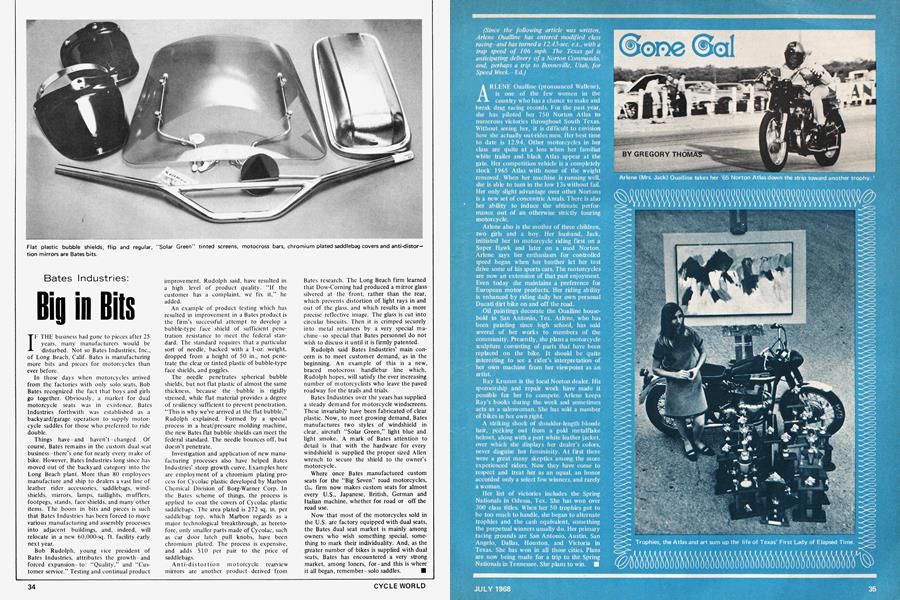

Investigation and application of new manufacturing processes also have helped Bates Industries’ steep growth curve. Examples here are employment of a chromium plating process for Cycolac plastic developed by Marbon Chemical Division of Borg-Warner Corp. In the Bates scheme of things, the process is applied to coat the covers of Cycolac plastic saddlebags. The area plated is 272 sq. in. per saddlebag top, which Marbon regards as a major technological breakthrough, as heretofore, only smaller parts made of Cycolac, such as car door latch pull knobs, have been chromium plated. The process is expensive, and adds $10 per pair to the price of saddlebags.

Anti-distortion motorcycle rearview mirrors are another product derived from Bates research. The Long Beach firm learned that Dow-Corning had produced a mirror glass silvered at the front, rather than the rear, which prevents distortion of light rays in and out of the glass, and which results in a more precise reflective image. The glass is cut into circular biscuits. Then it is crimped securely into metal retainers by a very special machine-so special that Bates personnel do not wish to discuss it until it is firmly patented.

Rudolph said Bates Industries’ main concern is to meet customer demand, as in the beginning. An example of this is a new, braced motocross handlebar line which. Rudolph hopes, will satisfy the ever increasing number of motorcyclists who leave the paved roadway for the trails and trials.

Bates Industries over the years has supplied a steady demand for motorcycle windscreens. These invariably have been fabricated of clear plastic. Now, to meet growing demand, Bates manufactures two styles of windshield in clear, aircraft “Solar Green,” light blue and light smoke. A mark of Bates attention to detail is that with the hardware for every windshield is supplied the proper sized Allen wrench to secure the shield to the owner’s motorcycle.

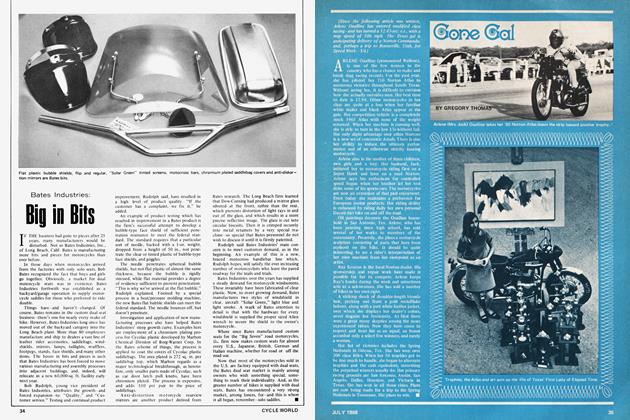

Where once Bates manufactured custom seats for the “Big Seven” road motorcycles, thv firm now makes custom seats for almost every U.S., Japanese, British, German and Italian machine, whether for road or off the road use.

Now that most of the motorcycles sold in the U.S. are factory equipped with dual seats, the Bates dual seat market is mainly among owners who wish something special, something to mark their individuality. And, as the greater number of bikes is supplied with dual seats. Bates has encountered a very strong market, among loners, for-and this is where it all began, remember-solo saddles. ■