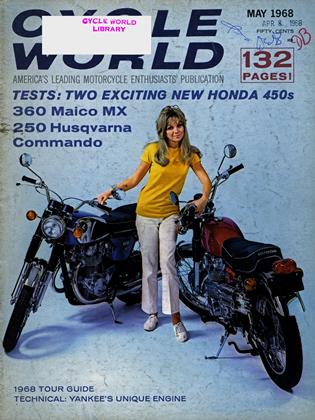

A Technical Analysis of an Engineering Adventure...

The Yankee Engine

IVAN J. WAGAR

The old cliche that necessity is the mother of invention might very well apply in the case of the unique Yankee engine design. Faced with the prospect of trying to find an astronomical sum to finance construction of a powerplant in the U.S., the minds at Yankee considered many possibilities before finally deciding to pair up existing single-cylinder engines.

The idea is not entirely original. The East German MZ concern developed a successful 125 racing two-stroke Single and, when it was time to go after 250 class awards, the brilliant Walter Kaaden housed two Singles on a special crankcase. The very fast Suzuki grand prix Twins are constructed in the same manner. Even Yamaha's RD 56 air-cooled 250 grand prix engine was, in basic concept, a pair of Singles with a central drive into the transmission.

All of these are rotary valve Twins, in which both sides of the engine are very busy, accommodating discs, housings and carburetors.

Taking the drive from the center of the crankshaft solves all sorts of engineering problems by elimination of overhang on the drive side shaft.

Yankee engineers were not required to take the drive from the center because, early in the program, it was decided the engine would be of pistori port design. However, the twoengine concept offers tremendous maintenance advantages. Providing the engines have been integrated properly, one can be easily removed for service or replacement without disturbing much else in the powerplant. Ease of maintenance, reliability and duplication of inexpensive components were the prime considerations behind development of the Yankee engine.

The independence of the two engines has been a major goal throughout the entire Yankee development program, and for a very good reason. Almost anyone with a knowledge of dirt riding, in which maximum tractibility is needed, will select a single-cylinder engine. While Yankee desired a large displacement Single, heat dissipation problems with large piston area can be difficult to overcome on a two-stroke engine in which the piston is subjected to heat on every stroke. When relatively small cylinder sizes are used, the distance from the center of the piston crown to cylinder walls is within reason. The heat problems encountered with a 500-cc Single, over a 250-cc Single would not be double, but four times as great.

Yankee's solution to the heat barrier is quite simple: One crank assembly is rotated 180 degrees relative to its mate, so that both pistons travel up and down together, and the engine is a 360-degree Twin. However, both cylinders fire at the same time, and as far as the rear wheel is concerned, the engine is a Single. As far as heat is concerned, however, the engine is a Twin. For road racing, street applications and smooth scrambles or TTs, the engine would perform better asa Twin. Regardless which configuration is purchased, it is a comparatively simple task to alter to suit the owner's needs.

In slow, muddy trials and enduro country, it is necessary to have considerable flywheel effect. On most trials two-strokes, including the Ossa, the added inertia is obtained by using heavy brass magneto flywheels, because the internal flywheels are very small, and must be kept small to maintain minimum crank chamber size. The Yankee carries exceptionally sturdy crank mainshafts to support the weight of trials-type flywheels. For road races, in which added inertia is not required, the lighter aluminum wheels will permit better acceleration and offer less crankshaft loadings in the 10,000-rpm range.

The two engines fitted to the special crankcase virtually are standard 230-cc Ossa units. In order to test all Ossa engine components to be used in the Yankee, Ossa built a 230 Single to Schenectady specifications for the Barcelona 24-hour race last year, and won the event overall, thus beating several 500 and 650 machines during the grueling race. It could be considered by some that the very first prototype Yankee actually won the 24-hour.

Though Ossa has managed a great deal of road racing success, the company builds one of the finest trials machines in the world. In between these two extremes there are excellent street, enduro and motocross versions of the 230 engine. What really is amazing, however, is that all engines, regardless of intended application, are given identical cylinder porting. Port height, width and timing are the same on all cylinders. In addition, the crankshaft, connecting rod and piston also are identical components in any 230-cc Ossa engine. Differences in effective port area and timing are achieved through use of a large or small carburetor on the intake side, and either restriction of or assistance to the exhaust gas flow through use of various exhaust systems. A trials machine, for example, is fitted with an unusually small carburetor and restrictive muffler design. A road racer, on the other hand, is given a very large carburetor and an expansion chamber-type exhaust pipe.

This flexibility will be carried into the Yankee engine. A rider who desires a docile woods machine need only purchase the basic machine in enduro guise; but when he desires more power, he will require only substitute pipes and/or carburetors. Compression ratios may be altered when an engine is to be changed from one extreme to the other, but, in this case, head gaskets of different thicknesses will be available for the purpose.

The jack of all trades cylinder is an aluminum casting with a pressed-in cast iron liner, which is easily replaceable. The generous finning could have been reduced, and cylinder centers brought closer together, but the 15-in. maximum width is not objectionable. And, if Yankee decides to fatten the inboard transfer ports, sufficient space has been allowed between the cylinder bores to permit thicker ports. The cylinder has a bulky appearance, due mainly to Yankee having retained the Ossa oversquare bore/stroke dimensions of 70 x60 mm. At the rear of the engine, in the footpeg region, the width is a conservative 9.5 in., and well inside the frame tubes.

(Continued on page 98)

YANKEE

The Yankee pistons are aluminum castings with a slight dome and two ring grooves. The 1-mm thick rings are quite unusual in that they have a rounded edge. Ossa has used the round contact face for more than two years with a high degree of success. One very important factor is that the rings bed in quickly, and considerably reduce break-in time. The cylinder head is concentric, with a central spark plug, to allow the shortest possible flame travel during combustion. A compression release is fitted into the head at a 45-degree angle approximately midway between the spark plug and the outside of the combustion chamber.

To accomplish complete integration, a rather massive, yet intricate central unit was designed. Measuring 12 in. across, the aluminum casting does not split horizontally, or vertically, but is a single, one-piece shell. Finning has been cast in a non-uniform pattern to permit maximum cooling where it is most required, particularly in the region of the individual crank chambers. Two heavy 5.5-in. wide mounting points at the rear and four independent 0.75-in. wide lugs at the front are an integral part of the casting, and are the points at which the engine is secured in the frame. Short of total destruction, it is inconceivable that it would be necessary to remove this portion from the chassis. In fact, the bare, machined casting may be installed in the frame and the entire engine built up, including all bearings and shafts.

The two crank assemblies are comprised of fully-machined, full-circle flywheels with a 12-ton press on the separate crankpin. Each flywheel and mainshaft is a one-piece forging. The connecting rod is a one-piece forging with needle bearings at both ends. Each crankshaft, fitted with two single-row ball main bearings, and double-lip crankcase seals, is inserted into the master casting horizontally. The assemblies are identical, and are interchangeable, right or left side. Inboard ends of the cranks carry a double sprocket to accept a duplex chain. Below and to the rear of the crank chambers, in a space not usually occupied in two-stroke Twins, is a transfer shaft with four sprockets which are in line with the sprockets on the crankshafts. The result is that the engines are locked together by the transfer shaft. Without the duplex drive chains, the engines are completely independent of one another.

The transfer shaft, which is supported at both ends by single-row ball bearings, protrudes through the master casting on the left side of the engine, into the primary drive cavity. A spur gear, fixed to the output end of the transfer shaft, delivers the drive to a large diameter clutch hub gear. The Yankee clutch is comprised of five steel drive plates, with bonded inserts. Six driven plates also drive the clutch center hub and gearbox mainshaft through small pitched teeth, rather than the fewer large, wide tabs found on some machines.

The clutch unit is in a special cavity, isolated from the primary drive chamber by an oil seal at the transmission mainshaft, and runs dry. Therefore, the clutch requires less spring pressure, which results in less rider clutch hand fatigue.

The Yankee’s transmission is quite unusual in that it is basically a six-speed box with provision for quick alteration to four or five speeds without removing the internals. So, whether the machine is to be used for AMA Class C competition, or events in which the number of speeds does not matter, there is complete rider flexibility in the number of gears he desires for a particular circuit or type of event. The transmission was originally designed for Ossa’s 250-cc rotary valve racer, and all internals have been sized to withstand more than 65 bhp.

Three choices of gearboxes will be offered; a wide ratio, suitable, for enduros and very rough terrain; an intermediate, for general recreation riding and an eventual street machine; and a close ratio set, expressly for road racing. Should an owner wish to make additional ratio changes, it is possible to exchange gears on the shafts to produce custom ratios. Still greater versatility is offered as the gear shifting pattern can be altered from up for up or down for up. Also, the gear shifter shaft passes through the entire engine, and the shift lever may be located to the right or to the left. There is a mounting lug for the rear brake pivot on either side of the frame, so that the lever may be fitted to the right or to the left.

Both transmission shafts, the shifter drum and the gear shifter shaft are fitted to an independent casting which is mounted on the left side of the gearbox. Thus, the complete transmission may be removed without disturbing the engines. The large diameter gear selector drum has three shifting forks to move mainshaft and layshaft gears into the various positions to obtain all six speeds. To keep wear to a minimum, the forks are 1-in. wide at their bases on the shifting drum. The added width also reduces the tendency for the fingers to tilt from the sideloading imposed during gear changing.

The forks are moved on the drum by an actuating pin fitting into annular grooves in the drum. In the Yankee, the pins are on eccentric screws, which are accessible through a small cover plate in the bottom of the gearbox, so that minute changes may be made to compensate for possible manufacturing variances.

The prototype engine is fitted with the successful breakerless Femsa electronic ignition system, although production models may use a similar Motoplat arrangement. Ignition occurs when flux density reaches a peak, as the flywheel magnet passes the stator coil. The resultant electrical impulse is fed to a solid state circuit and then triggers an SCR, which is molded into the high voltage coil. Because there are no mechanical parts in contact with one another, the system is very reliable and foolproof, requiring no adjustment once it is properly timed.

All engine castings on the prototype were constructed of aluminum alloy; dry, the total weight was 96 lb. This figure can be reduced by using magnesium components, which may be the case with some special racing engines. The Yankee engine is, in every respect, an unusually high quality unit. It is refreshing to see such adaptation of existing components to create an engine which is quite different in overall concept.

View Full Issue

View Full Issue

More From This Issue

-

Round Up

May 1968 By Joe Parkhurst -

The Service Department

May 1968 By John Dunn -

Letters

LettersLetters

May 1968 -

The Scene

May 1968 By Ivan J. Wagar -

Ruin To Record

Ruin To RecordOut of the Rubble of World War Ii Came the Nsu Twin of Wilhelm Herz — the First Motorcycle To Break 200

May 1968 By Richard C. Renstrom -

Fiction

FictionThe Pickup

May 1968 By Robert Ricci