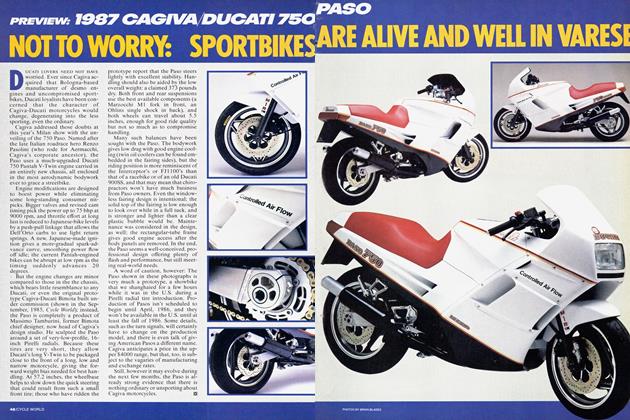

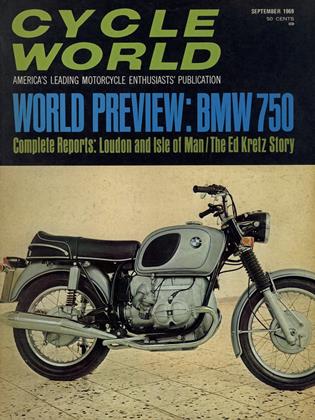

PREVIEW: BMW 750-cc R 75 US

The Opposed Twin Follows Suit

IVAN J. WAGAR

AMONG THE hard core motorcycle touring enthusiasts of the world there are about three groups that favor Twins. These Twin devotees can be divided into Vees, Verticals and Horizontals. The latter group, for reasons known only to themselves, have developed into the most rigid, adamant bunch of “individuals'' in motorcycling. They are “individuals" because the near $2000 price tag is nothing for the supreme product. Most Horizontal fans think nothing of spending another $200 for a pair of upswept pipes or $350 for a pregnant gasoline tank to make their “pure" Horizontal different from the one down the street.

Not only is the hard core Horizontal addict prepared to go on an enormous dollar binge, he also reads every word published anywhere in the world for and against his brand. To this group, the advent of a 750-cc BMW will be no surprise. They have read for the past couple of years accounts of experimental 750-cc mounts in the International Six Days Trial, and of a down-the-street machinist in Germany making 750-cc conversions for existing BMWs.

So, to the Horizontal Bunch, the all-new R 75 might be old hat. On the other hand, those among us who look on motorcycles as fun, rather than tradition, will find it interesting that Bavarian Motor Works has not been sitting still while manufacturers in England and the Orient have built and shipped their 750-cc muscle machines to this country.

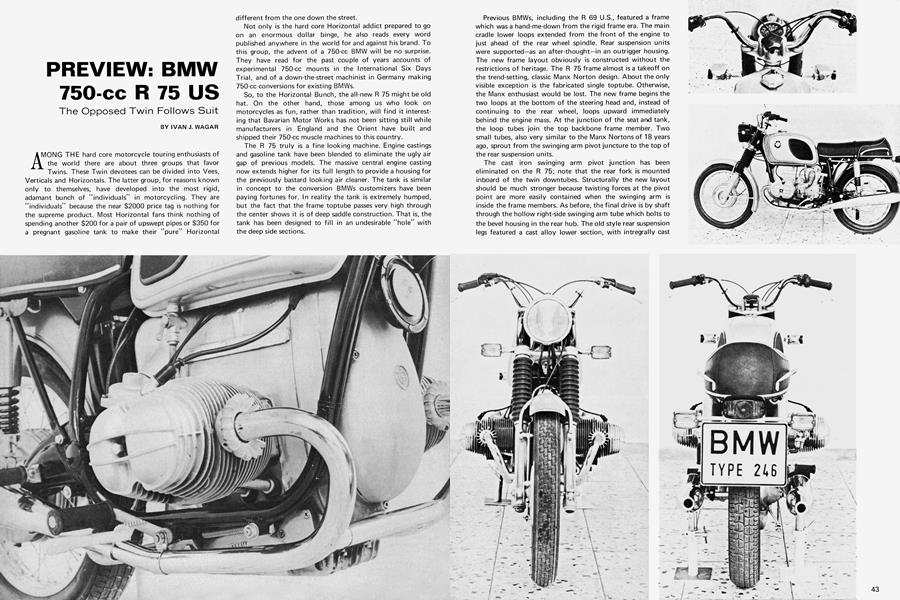

The R 75 truly is a fine looking machine. Engine castings and gasoline tank have been biended to eliminate the ugly air gap of previous models. The massive central engine casting now extends higher for its full length to provide a housing for the previously bastard looking air cleaner. The tank is similar in concept to the conversion BMWs customizers have been paying fortunes for. In reality the tank is extremely humped, but the fact that the frame toptube passes very high through the center shows it is of deep saddle construction. That is, the tank has been designed to fill in an undesirable “hole" with the deep side sections.

Previous BMWs, including the R 69 U.S., featured a frame which was a hand-me-down from the rigid frame era. The main cradle lower loops extended from the front of the engine to just ahead of the rear wheel spindle. Rear suspension units were supported—as an after-thought—in an outrigger housing. The new frame layout obviously is constructed without the restrictions of heritage. The R 75 frame almost isa takeoff on the trend-setting, classic Manx Norton design. About the only visible exception is the fabricated single toptube. Otherwise, the Manx enthusiast would be lost. The new frame begins the two loops at the bottom of the steering head and, instead of continuing to the rear wheel, loops upward immediately behind the engine mass. At the junction of the seat and tank, the loop tubes join the top backbone frame member. Two small tubes, also very similar to the Manx Nortons of 18 years ago, sprout from the swinging arm pivot juncture to the top of the rear suspension units.

The cast iron swinging arm pivot junction has been eliminated on the R 75; note that the rear fork is mounted inboard of the twin downtubes. Structurally the new layout should be much stronger because twisting forces at the pivot point are more easily contained when the swinging arm is inside the frame members. As before, the final drive is by shaft through the hollow right-side swinging arm tube which bolts to the bevel housing in the rear hub. The old style rear suspension legs featured a cast alloy lower section, with intregrally cast knobs which permitted the operator to adjust the stiffness of the springs without the aid of tools. The new units on the R 75 are very similar to Girling legs, but have a sheet steel handle welded to the adjusting cam on the lower spring flange. The complete front fork assembly is identical to that used on last year's U.S. models.

Mounting passenger footpegs and mufflers was an easy task on the old frame with the loops extending to the rear wheel. Now that the frame is similar to current design trends, it has been necessary to build two small sheet metal fabricated mounts to perform the chores. The mounts are welded to the swinging arm juncture of the main cradle, and are quite short, leaving some 20 in. of overhang for the heavy mufflers.

The new BMW's rear fender is quite interesting from an engineering point of view—there is no hinged rear portion to permit easy removal of the wheel—another indication of appearance taking precedence. CYCLE WORLD'S last BMW test machine was the R 60 U.S., which featured alloy rims; previous models used steel rims. The R 75 employs the new steel deep side rims, which offer light weight but are very strong, and have a similar appearance to alloy wheels. The front brake is a twin leading shoe unit, while the rear is of single leading shoe design. Both front and rear hubs are cast alloy, with iron liners, and have chrome-plated discs on the side opposite the brakes. Recently at Hockenheim, a fourshoe, dual front brake was tried on a machine based at Munich (factory sponsored), and it is assumed that this unit will be fitted to future larger displacement BMW models.

Heart of the R 75, the engine, is an all new design, not simply a punched out version of an older configuration. The whole engine is slightly tilted in the chassis so that the drive shaft line is nearer to the angle of the engine in the frame. All major engine castings, besides being much more massive, are different from previous engines. The camshaft now is located below the crankshaft, and pushrod tubes are underneath the cylinders. Thus the visible top of the engine is more attractive. Cylinders now are cast aluminum with iron liners, and the finning blends with that on the cylinder heads.

Throughout the engine, extensive use has been made of deeply recessed alien head screws. All flanges have very thick reinforcing bosses for the screw heads to bottom in the aluminum castings for maximum support at the flanges. Mating widths at all joints are sufficiently wide to ensure an extremely oil-tight engine, despite the enormous castings which will grow and shrink rather large amounts during use. The R 75 which was made available to CYCLE WORLD featured sand castings throughout. And, while the factory would like to adopt die cast techniques for production models, no top level decision has been made at this point to eliminate the rough sand castings.

Overall appearance of the machine could have been improved in the region of the battery if some sort of sheet metal or cast aluminum covers had been designed to continue the upper engine castings rearward beyond the air cleaner compartment. As it is, the battery is the only ugly spot on an otherwise pleasant design.

Basic engine layout is the same as on the first BMW motorcycle introduced some 46 years ago—the horizontally opposed Twin. The advantage of an opposed piston engine is that almost all reciprocating forces are canceled, and vibration is quite nonexistent. One of the major disadvantages—and one blissfully ignored by the Horizontal Bunch—is the effect of the machine attempting to rotate about the axis of the crankshaft under acceleration or deceleration. It is, after all, a very basic fundamental of physics when the crankshaft is in-line with the motorcycle. And the greater the flywheel effect, the greater the tendency for the machine to exhibit this unusual characteristic. After a rider has spent some time and miles on a transverse design, he becomes accustomed to rotational effect and allows for it in his riding habits. From that point on, the pluses of smoothness seem to offset the minuses of an in-line crank.

The crankshaft of the R 75 is mounted in four main bearings. It was suspected that BMW would make an attempt to incorporate a center main bearing assembly in the new design to eliminate crankshaft whip at high crankshaft speeds. That would mean, however, that the cylinders would necessarily be considerably out of line, an undesirable trait in an

opposed Twin layout. In an attempt to overcome the need for the rigidity of a middle main bearing, the crankshaft has been made huskier than even before.

To emphasize the strength of the crankshaft we should explain that this engine has been built in versions up to the 900-cc, without crankshaft failures. The 900-cc R 90 is due to be released later. Along with the R 75 will be two smaller versions, of 600and 500-cc displacement. The R 50, R 60 and R 75 all feature the same stroke of 70.6 mm, resulting in an extremely over-engineered bottom end for the 500 in order to have tooling uniformity throughout the line. Where the 500 has an undersquare bore/stroke ratio of 67/70.6, the 750 engine is in much better shape at 82/70.6, considerably oversquare. Thus, the R 75 has a very low piston speed (in the region of 3000 ft./min.) at the rated maximum of 6400 rpm, where the engine is claimed to produce its maximum output of 57 bhp, to give a claimed top speed of 115 mph.

Carburetion for the R 75 will be handled by a pair of Bing units, new in concept. During tests of BMW prototypes in the ISDT in the past few years, various types of Japanese Keihin carburetors were experimented with to discover the satisfactory balance between demand and consumption on quick throttle openings. Bing now has produced a carburetor so close in design concept that it must in some respects infringe on Keihin patent rights. Be that as it may, the new Bing has a vacuum demand operated slide which produces an over-rich mixture during the crucial first instant of rapid throttle opening, much the same way as the acceleration pump on American automobiles. The major difference is that the accelerator pump tosses a gush of raw gasoline into the inlet track, whereas the diaphragm carburetor causes a delay in admitting more air quickly. A greater vacuum is produced in the venturi and the engine sucks in a larger portion of fuel until the slide begins to open. The system is extremely efficient, and more economical than the squirts of raw gasoline from an accelerator pump.

Altogether new for BMW is an electric starter, which will be standard on the 600 and 750 models, and an optional item on the 500. However, the factory has opted to retain the traditional side acting kick starter, probably because of the smallish battery. Most factories going to electric start have done away with the kick starter, reasoning that, with sufficient amperage available, the chances of not starting are the same as with the modern auto—just about nil.

At this time plans are going along very well for the new units. Early in the year it was believed the new machines would be ready for release in June. But production delays moved the date to August. Now Berlin skeptics have predicted a delay until December. The new R 75 will not be built at the old Munich plant, but at a new plant at Spandau in Berlin. This does not, of course, mean the machine's name will be changed from the traditional BMW. It does mean that the present work force of 450 employees is to be increased by 50 to meet the demand schedules imposed by the need to have the new models in production at a rate of 1000 units per month before September. CYCLE WORLD'S advertising department has a special all-color layout for the October issue to announce the R 50, R 60 and R 75. From that we can assume that everything is going as planned, and that the machine will, indeed, be available for sale in September.

The R 75 marks a completely new trend for BMW. Gone is the strict adherence to 46-year-old practices and design innovations; in most respects, the new R 75 is in line with what everyone else is doing and, therefore, it will be interesting to see how BMW fares when meeting the competition head on.

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsRound Up

September 1969 By Joe Parkhurst -

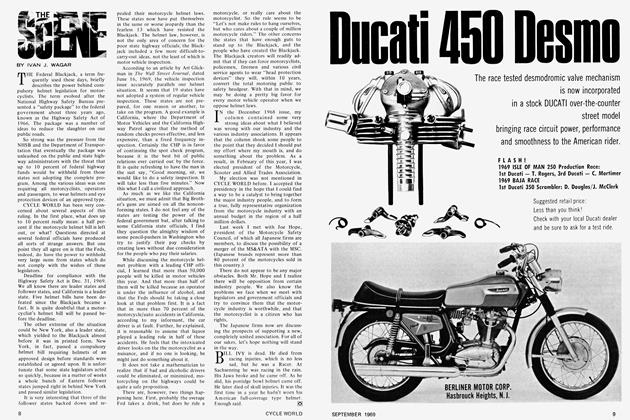

Departments

DepartmentsThe Scene

September 1969 By Ivan J. Wagar -

Departments

DepartmentsThe Service Department

September 1969 By John Dunn -

Letters

LettersLetters

September 1969 -

Competition

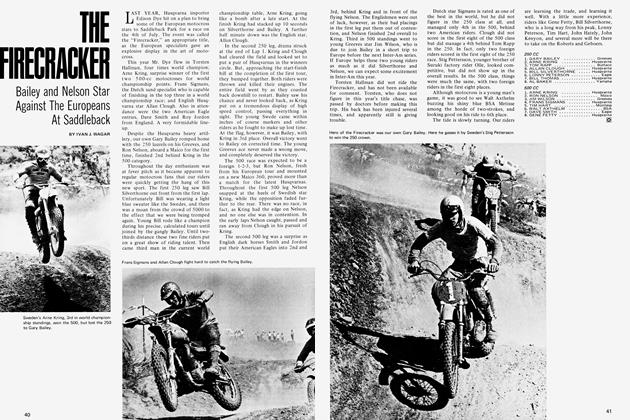

CompetitionThe Firecracker

September 1969 By Ivan J. Wagar -

Competition

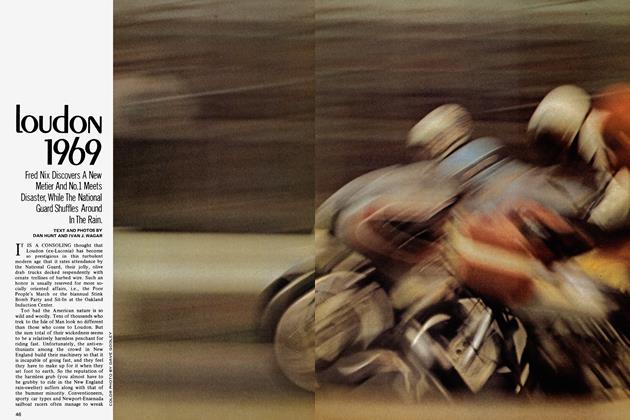

CompetitionLoudon 1969

September 1969 By Dan Hunt, Ivan J. Wagar