SERVICE DEPARTMENT

JOHN DUNN

350 KIT

I recently purchased a Webco 350 kit for my Honda Hawk 305. Also, number 7164 cams have been installed. I purchased the bike new in 1965 and had 4,000 miles on the engine before the kit was installed.

My questions are these:

1. Should the engine now be timed on the marks as the manual states, or is there some other setting? 2. What number spark plugs should I use for summer and winter? 3. What weight oil should I use to break the engine in, and then what weight should be used?

After spending quite a bit to have this conversion done, 1 am afraid to run the bike until 1 get this information, as 1 could not afford to replace anything if it were damaged because of improper timing, etc.

1 have called all the local dealers and 1 get no two answers that are the same. 1 was going to do the following, but am not sure this is correct. 1. Time the engine as stated in the Honda Manual. 2. Use a D-8H plug in winter and a D-9H in summer. 3. Break the engine in with BSA oil No. 30 weight for about the first 60 miles, then change to Castrol R racing oil 40 weight and use this all-year round.

Stanley Sirkis Beltsville, Md.

The 350 conversion will result in a higher compression ratio than standard (from 8.5 to 1 to approximately 9.5 to 1). The higher ratio will require some consideration, and it is advisable to start by using a super premium fuel. It may be necessary to retard the ignition timing slightly to best suit the increase in ratio. I would suggest that you start with the standard ignition advance of 45 degrees total and then try it with 42 and 40 degrees total.

Due to the increase in ratio, it may also be necessary to start with D-9H spark plugs; however, they may prove to be too warm when the machine is ridden hard. It therefore may be necessary to go to D-10H after the break-in period.

The SAE 30 oil to which you refer will be suitable providing the ambient temperature is above 50°F. If not, use a SAE 20W 20. After break-in, I would recommend that you use a SAE 30 in the winter and a SAE 40 in the summer. It is not good practice to use a castor base oil for street applications. It is only beneficial under extreme operating conditions, and castor-type oils are not suitable for conditions of cold and stop and start operation. If you decide to change from the castor back to a mineral oil at a later date, this would also present* a problem, because it is necessary to completely clear the castor oil from the engine before using the mineral oil. If this is not done, severe engine damage is likely to occur. Although there are special flushing liquids available, the only sure way of being certain that all the castor has been removed is to completely dismantle the engine and thoroughly clean all the components.

(Continued on page 27)

REVERSE

It might be my lack of knowledge about two-stroke engines, but can an engine of this type run in reverse? I have seen an Allstate Moped engaged into first gear pushed backwards, and it started. It could run all the time. I understand that he may have messed up the transmission, but it ran forward in first and backwards in first. Please explain this if you can. It is mighty surprising to see this happen.

Robert Dart Berryville, Va.

Yes, a two-stroke engine can easily be made to run in a reverse direction. There are two major factors that will determine the direction of operation: the direction of rotation during cranking prior to starting, and the point where ignition takes place, generally referred to as ignition timing. In other words, it would be possible to take any conventional, normally aspirated twocycle engine, where all functions of intake and exhaust are controlled by the piston (does not include rotary valve engines), and alter the point of ignition timing from a specified position before tdc to the same point after tdc. If the engine was then rotated in a reverse direction, the engine would start and then continue to run in the reverse direction just as efficiently as it did in the correct direction, providing there were no mechanical ignition advance mechanism.

In fact, the German Messerschmitt three-wheeled cabin cruiser employed this principle to provide a means of reverse. It was equipped with a Bosch flywheel starter/generator unit that was provided with a separate contact breaker assembly and circuitry that provided the required change in ignition timing to allow reverse operation.

Some two-strokes will run in reverse without altering the ignition timing.

POWER HUNGRY

I own a 1966 Yamaha 305 My problem is the lack of hop-up equipment on the east coast, and for that matter, for this mode! in general.

The compression ratio on this mode! is 7.1:1, which is fairly low for a two-stroke, presumably to aid in overall performance and endurance. What would be the amount of milling I would have to do to raise the compression to 9:1 or 10:1? Would these compressions be practical for the street?

Since a new compression wouldn’t “jive” with the old port timing and carburetion, would any extensive work have to be done to obtain maximum performance? How much of a colder plug would be needed for increased compression?

Finally, would a Snuff-or-Not sufficiently silence expansion chambers so they could be practical for the street? If not, would the exhaust from the new 305 scrambler be any better?

Any help or suggestions for the above would be appreciated.

Wayne Kunkel Syracuse, New York

A small increase in compression ratio can be employed on a two-cycle engine without making any changes to the port timing. Generally, an increase of half a ratio should be considered as maximum.

A high compression ratio will theoretically result in an increase in combustion temperature and pressure. If the pressure in the cylinder is higher than the transfer port pressure at the time when the transfer ports open, this will result in an adverse condition by delaying the induction of the fresh charge into the cylinder. To improve this situation it is necessary to decrease the cylinder pressure at this time or increase the pressure in the transfer ports. To increase the transfer pressure is not easily achieved without resorting to complicated modifications. However, the pressure in the cylinder can sometimes be successfully dropped at the time of transfer opening by opening the exhaust port sooner. Whatever benefits are achieved without the use of a dynamometer and suitable research instrumentation will only be due to good guesswork.

(Continued on page 28)

An easy way of altering the exhaust port timing can be achieved by machining or filing the piston crown adjacent to the exhaust port to obtain an earlier opening. It provides an easy way of experimenting, and, at the worst, you have only ruined the piston. For street applications, I would suggest trying a 8.5:1 compression ratio on your machine and lowering the top edge of the piston approximately 2mm in line with and the same width as the exhaust port. If this proves to be successful, it would then be best to replace the pistons and then increase the height of the exhaust port by 2mm. The reason for this is because it is not really good practice to reduce the piston top land width and thereby subject the top ring to higher operating temperatures.

The higher ratio will warrant a colder spark plug, the ignition timing may have to be retarded 2 to 5 degrees, and it may be necessary to go a little richer on jetting.

I hope these few words have given you an idea of what is involved, Wayne. Only alter one thing at a time, when possible. Then you will be able to judge what effect each stage has. Let me know how you get on, as I am sure that other readers will like to know if you are successful.

We have not tried Snuff-or-Nots on a two-stroke with expansion chambers, but we are sure they will not work. If you want to be legal use the standard mufflers; they are quiet and very efficient.

GEAR RATIOS

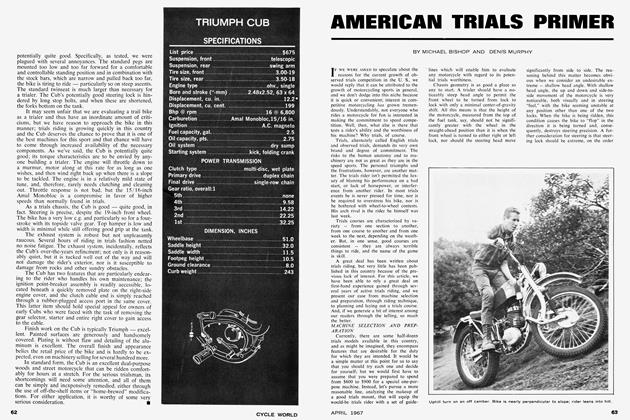

How does one figure the overall gear ratios from the following information? This is from a brochure of Bultaco’s 175cc Campera.

TRANSMISSION

Primary — 2.37 engine revolutions to one on gearbox.

Secondary — 3.85 revolutions on gearbox to one on wheel.

Overall ratio — 9.12 revolutions of engine to one on wheel.

Counter-shaft sprocket — 14T.

Rear wheel sprocket — 54T.

GEARBOX RATIOS

1 ........0.350

2 ........0.586

3 ........0.831

4 ........1

I’ve seen this type of information given before and would like to know how to figure it all out, so I can come out with the overall ratios like you give in your road tests, that is, 1st— 24 to 1; 2nd — 17 to 1, etc.

Ben H. Bowman Port Angeles, Wash.

If the primary drive, internal gearbox and final drive gear ratios are known, it is relatively simple to work out the overall ratio for each gear. Bultaco differ from the majority of motorcycle manufacturers in the way in which they show the gearbox internal ratios. They express the ratio backwards, showing how many revolutions the gearbox input shaft will make to one revolution of the output shaft. It is normal to show how many revolutions the output shaft makes to one revolution of the input shaft. However, this does not make it anymore difficult to work out the overall ratio for each gear, providing one recognizes the method used for displaying the internal ratios.

In all cases, multiply the primary drive ratio by the secondary (rear or final) drive ratio. It is usual to then multiply the answer by the gearbox internal ratios to arrive at the overall ratios for each gear. Example:

Primary ratio 2.37 to 1 Secondary ratio 3.85 to 1 2.37 x 3.85 equals 9.12 1st gear internal 2.85 x 9.12 = 26 to 1 overall 2nd gear internal 1.70 x 9.12 = 15.5 to 1 3rd gear internal 1.20 x 9.12 = 11 to 1 4th gear internal 1.00 x 9.12 = 9.12 to 1 In the case of the Bultaco method, it is necessary to divide the product of the multiplied primary and secondary ratios by the internal gearbox ratios. Example: 1st gear 9.12 -F 0.350 — 26 to 1 overall 2nd gear 9.12 -F 0.586 = 15.5 to 1 3rd gear 9.12 -F 0.831 = 11 to 1 4th gear 9.12 -F 1.000 = 9.12 to 1 I hope this answers your question, Ben.

(Continued on page 30)

HONDA HOP-UP

I own and race a 1965 Honda S-90, which placed second in the state point standings for 1966. 1 am having troubles with the bike, to put it mildly. 1 am not satisfied by its performance at the present time. 1 have installed a Honda CB-160 1/8-over piston, along with a Weber cam and Webco valve springs. 1 ran the machine this way for over a year, then decided to try to get better performance out of it by adding a few little “goodies.” The first was to fit a 26mm carb on the bike, then to smooth out the ports. After this was completed, the problems started. By playing with the metering needle and various numbered jets, ranging from a 70 to 160, 1 found that it ran best with a 140 jet (which, in turn, made the bike run worse, rather than improving overall performance).

Could you tell me what 1 am doing wrong? Do you think that the bike is over carbureted, or am 1 just not getting the right combinations in the carburetor?

Tim Wolf Denver, Colorado

The Honda S-90, when equipped with the standard 20mm carburetor, is far from being under carbureted when operating at a maximum engine speed of 9,500 rpm. The following remarks have been made on the assumption that you are still employing 9,500 rpm as a maximum operating speed.

When considering a change of port and carburetor size, it is accepted practice to consider the theoretical mean gas velocity at the port or carburetor venturi prior to making any change. To provide adequate operating conditions throughout the usual engine speed range of a road racing motorcycle, a minimum gas velocity of 250 feet per second is considered as optimum when computed at maximum engine speed. Any lower values will, in the majority of cases, adversely affect mid-range torque.

When this theory is applied to the S-90 and computed at 9,500 rpm, the mean gas velocity with a 20mm carburetor will be 285 feet per second. A 22mm instrument would reduce this to 245 feet per second and the 26mm unit employed by you would result in the very low figure of 176 feet per second. On the basis of this investigation it is indicated that the 26mm carburetor and subsequent port modifications are of excessive size. The 22mm carburetor would be the most logical approach. The 22mm instrument may prove to be slightly on the large size, but in conjunction with other intake and engine modifications, is definitely worth trying.

Theory is based on the results and experiences of successful engineers. Quite often it only applies to a certain set of conditions, but in most cases, can be relied on to provide information which is approximately correct and does make it possible to be very near the most suitable condition without resorting to a lot of costly trial and error. The following simple calculation is given for computing mean gas velocity at the port.

Mean gas velocity through port in feet per second equals:

Mean piston speed D' 60 X

Where,

D — Diameter of piston d = Diameter of port.

Either inches or millimeters can be used on the right of this equation, providing both values are of the same scale.

To find the mean piston speed, use the following equation:

RPM x stroke in inches. -2-(feet per minute) 6

I hope this information will be useful to you, Tim, or any other reader who is contemplating a carburetor port change.