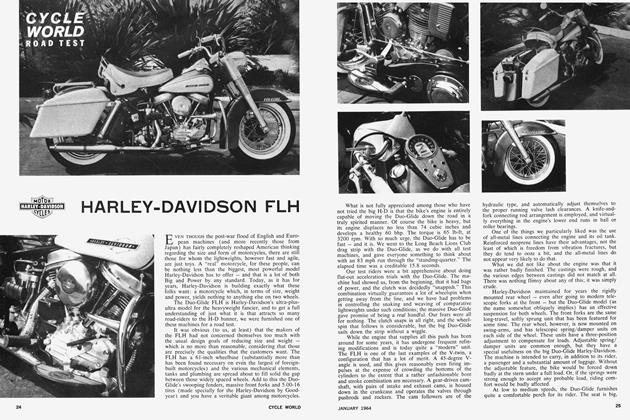

ROAD TEST & TECHNICAL ANALYSIS:

CYCLE WORLD ROAD TEST

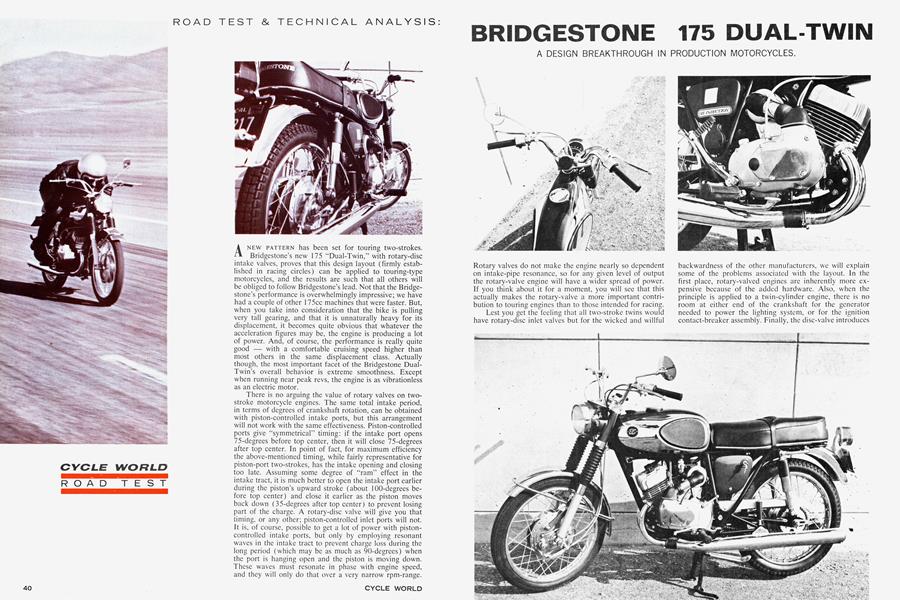

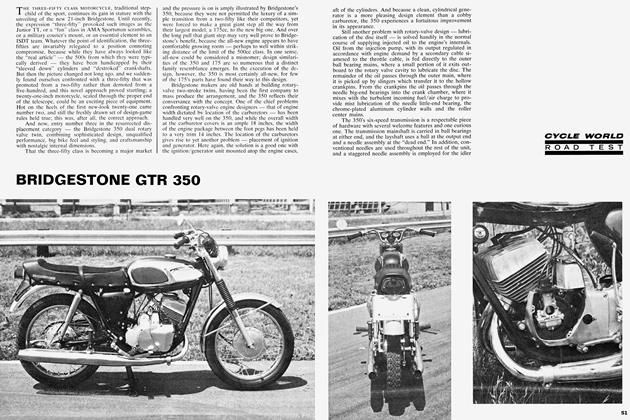

A NEW PATTERN has been set for touring two-strokes. Bridgestone's new 175 "Dual-Twin," with rotary-disc intake valves, proves that this design layout (firmly established in racing circles) can be applied to touring-type motorcycles, and the results are such that all others will be obliged to follow Bridgestone's lead. Not that the Bridgestone's performance is overwhelmingly impressive; we have had a couple of other 175cc machines that were faster. But, when you take into consideration that the bike is pulling very tall gearing, and that it is unnaturally heavy for its displacement, it becomes quite obvious that whatever the acceleration figures may be, the engine is producing a lot of power. And, of course, the performance is really quite good — with a comfortable cruising speed higher than most others in the same displacement class. Actually though, the most important facet of the Bridgestone DualTwin's overall behavior is extreme smoothness. Except when running near peak revs, the engine is as vibrationless as an electric motor.

There is no arguing the value of rotary valves on twostroke motorcycle engines. The same total intake period, in terms of degrees of crankshaft rotation, can be obtained with piston-controlled intake ports, but this arrangement will not work with the same effectiveness. Piston-controlled ports give "symmetrical" timing: if the intake port opens 75-degrees before top center, then it will close 75-degrees after top center. In point of fact, for maximum efficiency the above-mentioned timing, while fairly representative for piston-port two-strokes, has the intake opening and closing too late. Assuming some degree of "ram" effect in the intake tract, it is much better to open the intake port earlier during the piston's upward stroke (about 100-degrees before top center) and close it earlier as the piston moves back down (35-degrees after top center ) to prevent losing part of the charge. A rotary-disc valve will give you that timing, or any other; piston-controlled inlet ports will not. It is, of course, possible to get a lot of power with pistoncontrolled intake ports, but only by employing resonant waves in the intake tract to prevent charge loss during the long period (which may be as much as 90-degrees) when the port is hanging open and the piston is moving down. These waves must resonate in phase with engine speed, and they will only do that over a very narrow rpm-range. Rotary valves do not make the engine nearly so dependent on intake-pipe resonance, so for any given level of output the rotary-valve engine will have a wider spread of power. If you think about it for a moment, you will see that this actually makes the rotary-valve a more important contribution to touring engines than to those intended for racing.

BRIDGESTONE 175 DUAL-TWIN

A DESIGN BREAKTHROUGH IN PRODUCTION MOTORCYCLES.

Lest you get the feeling that all two-stroke twins would have rotary-disc inlet valves but for the wicked and willful backwardness of the other manufacturers, we will explain some of the problems associated with the layout. In the first place, rotary-valved engines are inherently more expensive because of the added hardware. Also, when the principle is applied to a twin-cylinder engine, there is no room at either end of the crankshaft for the generator needed to power the lighting system, or for the ignition contact-breaker assembly. Finally, the disc-valve introduces a double-barreled lubrication problem. Extra oil is required to lube the disc and the crankcase surfaces it bears against, and to insure that enough oil reaches the connecting rods' "big-end" bearings. Because mixture from the valve disc is led into a transfer port, instead of being aimed directly at the gap between the flywheels (as is the case in a pistonport engine), not as much of the total amount of oil going in actually reaches the rod bearing and to compensate for this a higher rate of oil input is required. The only way around this last problem is to feed oil directly to the bearings, through crankshaft oilways, and that introduces still more complication and expense.

Provided the difficulties can be resolved, the disc-valve two-stroke is most definitely superior to its piston-port counterpart — and Bridgestone has handled the difficulties with imagination and a high degree of effectiveness. For example: the knotty problem of a generator and ignition system was solved by making this a single assembly, and mounting the assembly behind the cylinders in the space usually occupied by carburetors. Drive to this assembly is picked up from the clutch-hub gear. A gear-type primary is used, giving a 3.41:1 reduction to the transmission, and as the generator/ignition drive gear has the same number of teeth as the crankshaft's driving gear, the ignition (and generator) turns at crank speed.

A potentially troublesome service procedure, timing the ignition, has been simplified by incorporating an 'idiotproof' top-center locating system. The far left-hand flywheel has locating holes drilled 180-degrees apart, and a pin, slipped in through a drilled (and normally plugged) hole in the side of the crankcase, indexes the crank with one piston or the other stopped at 21-degrees before top center. Set the appropriate points to break, pull the indexing pin, rotate the crank 180-degrees, re-index, and set the other points.

Automatic oiling has been provided on the Dual-Twin engine. A small, variable-output pump is mounted on the kft-side rotary-valve cover and driven from the end of the crankshaft. Output varies with engine speed, and there is an over-riding control linked to the throttle, so the quantity of oil going to the engine is automatically regulated to suit the requirements of the moment. Oil is drawn from a reservoir tucked away under the fuel tank, and is delivered by the pump to orifices in the carburetor mounting stubs, just ahead of the rotary valves.

No information is available as to the proportion of oil, relative to fuel, being fed to the engine by the pump, but it is somewhat greater than for other pump-lubricated two-strokes. The Bridgestone Dual-Twin trails a very noticeable haze when much throttle is applied; we would estimate the full-throttle oil/fuel ratio to be in the order of 16:1, which drops to probably 25-30:1 under 55 mph steady cruising conditions.

The Dual-Twin's crankshaft follows conventional twostroke practice, with pressed-in crankpins that serve as inner races for caged needle-roller bearings. More of these bearings (but smaller) are used at the piston-pin ends of the rods. The mainshafts are carried in ball bearings. Service has, again, been made easier by the fact that the crankcases separate along a horizontal centerline. You can invert the engine, remove a handful of nuts, lift the base crankcase-half and not only the crank but all of the transmission shafts are exposed and ready for removal.

Rotary valves, in addition to the benefits already listed, have freed the space at the back of the Dual-Twin's cylinders for an extra transfer port. This third-port layout does wonders for power output. The cylinders are aluminumalloy castings, with hard-chrome plating on the bores, which is expensive but gives excellent cooling and all but eliminates the possibility of piston seizure as piston and cylinder, being of the same material, expand at the same rate. We put this theory to the ultimate test by running our test machine flat-out right from the first — and we started with a new motorcycle.

The transmission setup used by Bridgestone for the Dual-Twin is unusual — and until you have ridden the bike a while you may wonder why they have provided a combined 4and 5-speed gearbox. A small lever on the side of the case is used to select a 4-speed "rotary" pattern (neutral, 1st, 2nd, 3rd, 4th, then neutral again and one more forward dab selects 1st); or a straight 5-speed (1st, neutral, 2nd, 3rd, 4th, and 5th). Ratios are: 1st — 2.61:1 ; 2nd — 1.67:1; 3rd — 1.24:1; 4th — 1.00:1; 5th — 0.85:1. You will note that 5th is an overdrive, and with the standard gearing it feels like just that.

When the "4-speed-rotary" combination is selected, the overdrive 5th is eliminated, which limits cruising speed. However, it does make for convenient city-street riding. No problems with finding neutral, which is just a nudge away from 4th, and no back-shifting when you stop for a traffic light. When the full 5-speeds are in use, there is a definite problem in finding neutral; if you don't get neutral before rolling to a stop, you won't get it at all. Also, the gear-change mechanism is a bit notchy on the shifts to 3rd and 5th. By and large, though, the transmission works very nicely, and the ratios are staged just right for the sporting rider. First is a bit tall, and one must slip the clutch when getting away from a stop, which really creates no problem because the bike has an excellent clutch.

With telescopic forks and swing arm, the Bridgestone Dual-Twin is a conventionally suspended motorcycle. Even so, the results are not altogether "conventional;" lots of travel in the suspension, and soft springing, gives this lightweight an outstanding ride. The balance is good, too, and the Dual-Twin handles exceptionally well. The center stand grounds if you try to corner too vigorously, but the bike is certainly impressively stable right up to the point of grounding.

Perhaps it was peculiar to the bike given us for test, but the brakes set up quite a shudder when stopping from any speed over 40 mph. Particularly, the double-leading shoe front brake, which (as in all motorcycles) takes the bulk of the stopping load. On the other hand, the shudder did not seem to materially affect braking performance; the Dual-Twin stops well from any speed.

For all-around riding, the Bridgestone Dual-Twin proved to be one of the most pleasant motorcycles we have had in many moons. The seat is comfortable, controls positioning is good, and the whole package is marvelously smooth. Starting, hot or cold, requires a minimum of effort and the performance is near enough to that of the average 250 to enable the Dual-Twin to keep up with any traffic you are likely to encounter here in America. One thing was missing and badly needed: a tachometer. The Bridgestone disc-valve engine will crank-off a lot of revs, and it would help keep things down to a reasonable level, and within the effective power range, to have a tachometer. A feature we especially appreciated was the kick-starter drive, which is fed directly through the primary reduction gears. You can pull the clutch in and start the engine even when the transmission is "in gear." No fumbling for neutral while those behind your stalled motorcycle get impatient.

BRIDGESTONE 175 DUAL-TWIN

$599.95z