SUPERCHARGING

GORDON H. JENNINGS

CONSIDERING THE LENGTHS tO which people will go to extract more power from their motorcycle’s engine, it is surprising that supercharging is so rarely employed. In the final analysis, no other measure, or combination of measures, will be half so effective. When dealing with an unsupercharged engine, the only means of getting appreciably more power is to increase the engine's operating speed. Power output is a function of how much air/ fuel mixture is taken in, burned and exhausted per unit of time and in the normally aspirated engine the only way of getting more mixture through the engine in any given amount of time is to increase the engine’s operating speed. Unfortunately, with increased operating speeds, there is less time available, through the working cycles, to get the mixture into, and exhaust products out of, the cylinder, so we must resort to “trick” valve timing to do the job and this has a disastrous effect on low speed running. Also, with increased operating speeds, the destructive effects of inertia arc increased at an alarming rate, and there are very sharp limits, even in specially designed racing engines, to how much flailing the moving parts will stand.

Within reasonable limits, no such problems exist for the supercharged engine. If you want to double the power output, it is not necessary to double the operating speed; just double the boost pressure. For example, if we have a 500cc engine that develops 40 bhp at 6000 rpm in unsuperchargcd form, then a supercharger pushing mixture into the engine at two atmospheres (atmospheric pressure, at sea level, is about 14.7 psi) would lift the output to 80 bhp — still at 6000 rpm. Also, the entire power curve would be lifted, and the engine would behave very much as though its displacement was lOOOcc; not the 500cc indicated by its bore and stroke (whatever those might be). Further increases in boost pressure would produce still further increases in power output, right up to the point where the load destroyed the engine, without any change in the peaking speed.

It should be obvious that all these wonderful things are not to be obtained entirely without penalty. The addition of a supercharger to an engine inevitably increases bulk and weight, not to mention overall cost, and there is precious little that can be done to reduce these; there is no possibility of eliminating them. Also unavoidable is the fact that some of the power gained from the boost pressure must be used to drive the supercharger. However, while several horsepower may be required to operate the supercharger, it is not a total loss. Although few people arc aware of the fact, the normally aspirated engine uses a lot of power in simply pumping mixture in and out of its cylinders. So, at moderate boost pressures, the amount of power absorbed in driving the supercharger is more or less balanced by the reduction in pumping losses. Still more of the power lost in driving the supercharger will be recovered because of the effect the clearance volume in the combustion chamber. With intake pressure at atmospheric, only as much mixture as is displaced by the piston will be drawn into the cylinder; the gases contained in the clearance volume start at atmospheric pressure, and finish there, and have no effect on the process. The situation is quite different in the supercharged engine: the clearance volume is left at atmospheric pressure (approximately) at the end of the exhaust stroke, but is pressurized during the intake stroke, so that at, for instance, two atmospheres boost pressure, our hypothetical engine will not only get more mixture in the cylinder, but it will be packed into the clearance volume as well. Assuming that our hypothetical engine has a combustion chamber clearance volume that constitutes about 15 percent of the total cylinder volume, then at a two-atmospheres boost we are not adding 100-percent more mixture than would be in the cylinder with normal aspiration, but 115-percent. Consequently, the power increase should go up to 86 bhp; not 80, as we said before. Clearly, the extra 6 bhp we gain from mixture crammed into the cylinder’s clearance volume will supply a large part of the total power required to turn the supercharger. It should also be clear that this effect will be most pronounced in engines having a low compression ratio, as in these engines the clearance volume is greatest.

From this, you may deduce that low compression-ratio engines are the ones that respond best to supercharging, and that deduction is correct. In the supercharged low compression-ratio engine we not only get added power from what would be, in a normal aspirated engine, wasted space, but the fact that the compression ratio is low enables us to use higher boost pressures before problems with thermal overloading and detonation are encountered. And, even more than simple pressure loadings, these are the things that limit the amount of boost an engine will withstand.

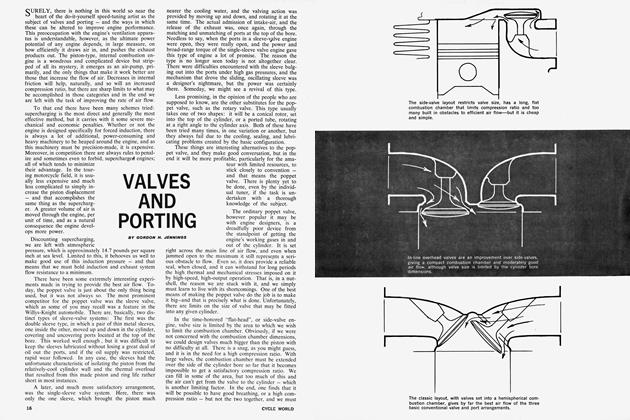

Difficulties with detonation are relatively easily overcome. You have only to reduce an engine’s compression ratio until detonation disappears, and there is even a method by which the limit can be determined before the supercharger is installed. It has been found that the compression ratio should be lowered as the boost pressure is raised in a proportion derived from the square roots of the absolute pressures involved. To illustrate this, let us consider an example where the original compression ratio of the engine in question is 10:1, and a boost pressure of two atmospheres is planned. To arrive at an adjusted “safe” compression ratio, use the following formula:

Where: R, is the original compression ratio R, is the adjusted compression ratio S is supercharge pressure, in pounds/sq. in.

Now then, the problem is merely one of finding the square root of 14.7, which is 3.835, then adding boost pressure to atmospheric (we are supercharging to two atmospheres, so it is 14.7 psi we get “free” and another 14.7 added by the supercharger) and taking the square root of that, which is 5.425. Then, divide the 5.425 into 3.835 and multiply the result by the original compression ratio, which gives us an adjusted safe compression ratio of 7.07:1, (all of these figures being as close as a slide rule can be read).

It should be understood that if an engine has an original compression ratio of, say, 7:1, and will run on the cheapest grade of fuel, then it will not be necessary to reduce that compression ratio when a supercharger is added. To arrive at the correct figure in such instances, one should use whatever compression ratio has proved near the limit in modified engines of the same type. A perfect example of this is provided by the 40 cubic-inch Triumph twin. In its most mildly tuned form, this engine has a compression ratio of 7.5:1; yet the same engine, in a super-tuned version, runs quite happily (on first-rate premium gasoline) with a compression ratio of 11.2:1. Obviously then, it would be possible to supercharge the 7.5:1 engine to at least 15 psi (which would constitute 2 atmospheres, absolute) without altering its compression ratio. By the same token, the 11.2 engine would need a set of the 7.5:1 pistons before it could be supercharged to any degree if severe detonation was to be avoided.

While problems with detonation are fairly easily overcome, there remains the problem of thermal overloading, and that is not so easily dealt with. Fortunately, heat flow into the engine does not rise directly with supercharge boost, as there are few engines, especially air-cooled motorcycle engines, that have enough reserve cooling capacity to handle a double load. However, there is more, and its effects must be taken into account. For example, the two-atmospheres boost we have been discussing would increase the heat flow into the engine by approximately 70 percent over the normally aspirated condition. Most motorcycle engines do have a cooling safety margin, to take care of such adverse conditions as when pulling up a steep grade in one of the lower gears under full throttle and with a relatively low air speed. We may expect that, in general, the “extra” capacity of the cooling fins to move heat from the cylinders into the air will be in the order of 200 percent of the normal requirement. In that case, our added atmosphere of boost would bring the normalcondition cooling load up to “170 percent,” very near the limit. And, that assumes normal cooling conditions, with the air moderately cool and with the bike moving rapidly enough to carry plenty of air past the cylinder(s). Thus, if any of you do add a supercharger to your motorcycle’s engine, you will be obliged to show a little restraint, and to be mindful of the effects of atmospheric and road conditions on the engine.

Under any and all conditions, you may be sure that the piston and exhaust valve in a supercharged engine have a difficult life. Heat input to these parts is always great, and they may not react at all well under the extra load, as they are operating quite near the limit in any case. If you plan to supercharge an engine to more than 7 psi, (about 1 Vi atmospheres) then plan to make some minor modifications inside. Piston clearances should be increased slightly, to insure against seizing, and if possible the standard exhaust valve should be replaced with one of the sodium-cooled variety.

Some of the heat problems can be overcome if it is possible, and practical, to use alcohol as a fuel. “Alky” soaks up a lot of heat as it evaporates, and this will serve to cool the engine internally. It has an especially beneficial effect on the piston crown, which will be bathed in cold alcohol mist on each intake stroke, and if long-overlap valve timing is provided, the supercharger will blow more cold alcohol mist out the exhaust port and over the exhaust valve. Needless to say, this measure will very substantially reduce the exhaust valve temperature.

Of course, in a road machine, it is not really practical to use alcohol as a fuel. Even if one could afford the stuff, it is rather difficult to obtain at one’s local friendly service station. So, in all touring bikes gasoline will be the fuel used, and that makes high-pressure supercharging (above two atmospheres) out of the question if any great degree of reliability is to be retained. You can, of course, resort to the same type of high-overlap valve timing to help cool the exhaust valve, but as the heat of evaporation for gasoline is much lower than that of alcohol, such measures are not nearly so effective. But, there is some justification for using a relatively rich mixture. With a mixture approximately 50 percent richer than the chcmicallycorrect value for a normally aspirated engine, the tendency toward detonation in the supercharged engine will

be greatly reduced. Tn practical terms, this may require that the pipes and passages in the carburetion system of a supercharged engine be made extra-large, so as to insure an adequate flow of fuel under all conditions. Obviously, even more flow capacity would be required for a supercharged engine running on alcohol.

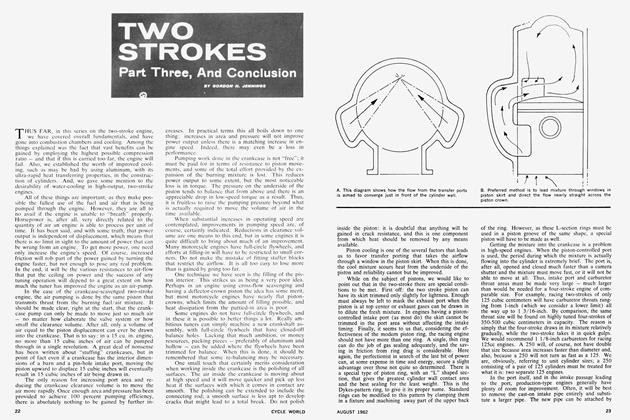

High-boost supercharging may also require that modifications be made to the porting and ignition systems. Most modern motorcycle engines have intake ports that are angled to direct the mixture into the cylinder toward one side, which imparts a swirl that speeds the combustion process. In the supercharged engine, the mixture is much more dense and is being blown into the cylinder under considerable pressure, so that combustion* will proceed nicely without the aid of any swirl effect. Indeed, any swirl that is added may very well be too much, and may have an adverse effect on the combustion process. Therefore, if boost pressures above 7 psi are in the offing, bear in mind that it may be necessary to revise the intake porting to lead the mixture straight into the cylinder, without any swirl. Also, because of the different combustion

characteristics, it will be necessary to reduce the amount of spark advance — the exact amount to be determined the hard way: by trial and error.

Due to the increased working temperatures, there is a greater tendency for carbon, sludge and varnish to form inside the engine. This danger may be minimized by using first rate high-detergent oils, which are compounded to resist burning into carbon and varnish in the first instance, and also contain detergents that clean away these unwanted deposits as they form. Particularly, such oils are valuable in keeping the rings free, and that is of great importance in a supercharged engine. Much of the heat entering the piston crown must escape to the relatively cooler cylinder walls across the rings, and this materially increases danger of carbon and varnish blocking the rings. Incidentally, you may simply assume that at boost pressures above 7 psi ring life will be reduced.

Here, we arrive at the question of what type of supercharger to use. For our purposes, we may consider that there are two types: first, the centrifugal supercharger, which uses centrifugal force acting on mixture being rotated rapidly by an impeller to pack the mixture out into a collector housing. The centrifugal blower is an extremely efficient device, but is limited in usefulness by its delivery characteristics. Because it is literally flinging air around, it does not do much at low speeds; it does not begin to work very hard until (in the rotor diameters that would be practical for a motorcycle) it is turning about 20,000 rpm. And, its output, once begun, rises sharply with increases in speed. If you had an engine that was centrifugally-blown, geared so that at a crank speed of 3000 rpm the blower impeller was turning 15,000 rpm with a delivery pressure of 3 psi, the boost would rise to probably 9 psi at 6000 rpm and at 8000 rpm the boost would be so high that pieces would begin to fly. (Also, at 8000 rpm crank speed, the impeller speed would be

40.000 rpm.) In short, you would have a thoroughly intractable engine, with little low-end torque and a tendency to get too strong at the upper end of the range. Then too, the 5:1 step-up drive, with the business end running at

40.000 rpm poses terrible mechanical problems. Insofar as the motorcycle is concerned, centrifugal blowers are not very practical unless variable-speed drives are used — and we shall get to that later.

The second type of blower that concerns us comes under the general heading “positive displacement.” The most common variety of positive displacement supercharger is the Rootes-type, of which the GMC truck engine blowers are an example. This is a sort of glorified gear-type pump, which bites off chunks of air and stuffs them into the engine. Because no compression takes place within the blower (only in the manifold behind it), the efficiency is rather low. On the other hand, as the rotor elements are phased by a pair of timing gears, and as there is some clearance between the rotors, and between the rotors and the case, there is no rubbing contact and the friction losses are quite low. The main disadvantages of the Rootes-type supercharger are that there is a lot of leakage back past the working clearances, and that it tends to deliver the mixture to the engine very much warmer than the air coming in the carburetor. An intercooler will solve the latter problem, although at some expense in bulk and weight, but the former we must be prepared to accept as unavoidable. In fact, the problem of leakage limits the overall usefulness of the Rootes-type blower, because it will be so great at low speeds that there is little pressure on the output side, and again when the pressure gets high the leakage tends to prevent it from going higher. In practice, the Rootes-type blower is limited to boost pressures of not more than 15 psi, at the upper limit, and it is better if they are not asked to pump more than 10 psi.

When higher boost pressures are required, and Rootestype supercharging is to be used (it is attractive for its great reliability and relative lack of bulk), then it will be necessary to pump the mixture in two stages. Use a large capacity blower to raise the mixture to 10 psi, and then a second, smaller blower to take that compressed mixture and squeeze it to 20 psi. That brings the mixture being fed to the engine up to almost 3 atmospheres pressure, and that is about as much as any engine not constructed specially for supercharging will stand.

We might mention at this point that it is most unwise to place the carburetor between the supercharger and the engine. In that position, not only the carburetor but the entire fuel system must be pressurized, to avoid having the fuel blown back through the system, and that needlessly complicates the overall mechanism. Also, it is best to feed fuel and air into the blower, as the evaporation of the fuel will then tend to cool the mixture compressed by the supercharger. Remember, when air is compressed, its temperature rises.

Vane-type superchargers, which compress the mixture internally, do not increase the temperature of the mixture nearly so much as Rootes-type blowers, and that is one of their best characteristics. Also, because the vanes actually contact the case, there is less leakage back and they will give more pressure at lower speeds and are willing to pump higher maximum pressures. Indeed, up to 30 psi of boost may be pumped in one stage. Unfortunately, due to the fact that there is contact between the vanes and the case, frictional losses are relatively high and oil must be fed into the blower to prevent rapid wear of the vanes. Finally, the vane-type blower is, by the very nature of its construction, rather bulky. One of these blowers was used on the streamlined MG that holds a class record at Bonneville, and that blower was literally almost as big as the engine. There is not really much choice in locating the supercharger on the motorcycle. The intake port, or ports, will be at the back of the engine, and that is where the supercharger should be. If long pipes are used to lead the mixture from the supercharger to the ports there will surely be a tendency for fuel to be lost from the air stream at low engine speeds, and thus low speed operation will be ragged. On the other hand, because on a single or twin cylinder engine the induction pulses are so widely separated, a buffer volume must be provided in the manifold. In the case of the twin, a buffer volume of twice the engine’s displacement will suffice; on a single, 3 or 4 times the piston displacement would be better. It should be understood that it is not necessary to have straight-through passages from the blower to the ports. The best arrangement is to simply dump the mixture coming from the blower into a chamber (which will serve as a large part of the overall buffer volume) and then have pipes, of the same diameter and length as would be required in the unsupercharged engine, leading to the intake ports.

Vertical twins having 180-degree cranks, and all Vtwins, have overlapping intake pulses. This means that there will be a marked tendency for the boost to be higher in one cylinder than the other, as the pressure in the manifold will rise and fall considerably as the intake valves open. An extra large buffer volume, at least 4 times as large as the displacement of the engine, will be required to reduce this effect to acceptable proportions. Otherwise, it is necessary to use different valve timings and ignition timings between the two cylinders to maintain even running.

Because it is necessary to have a large volume of fuel/ air mixture in the manifold, and because the best of engines will backfire occasionally, some sort of pop-off release valve will have to be provided on the manifold. When this is not done, the backfire will either wreck the manifold and/or blower, or it will blow open the intake valves (which is not bad, unless they foul the exhaust valves or the pistons), or all three. The pop-off valve does not have to be very fancy — a spring-loaded disc will do the job nicely — but it does have to be big enough so that the pressure in the manifold will be released immediately.

Although a conventionally driven centrifugal blower is too inflexible in its output to be of much use on a motorcycle, variable-speed drives will make it work and work well. At present, the only practical way to do this is to use an exhaust-driven turbine to turn the supercharger. The Chevrolet Corvair (the supercharged model) has an arrangement of this sort, and there is no reason why it could not be successfully applied to a motorcycle engine. The boost would not be too high, but it would give an increase and the entire turbine/blower unit is small enough to fit nicely behind the bigger motorcycle engines. The exhaust plumbing might be a trifle difficult to ac-

commodate, and all “tuned" effect in the exhaust system would be lost, but it would certainly seem that the gain would be worth all this. Incidentally, when this type supercharging is used, the exhaust pipes should be wrapped with insulation to prevent any heat loss between the engine and the drive turbine, as that heat represents energy that the turbine will need to do its job.

All theoretical considerations aside, one of the most serious difficulties encountered in supercharging a motorcycle is simply finding a suitable supercharger. The big GMC blowers are far too large (even the 3-71) to be practical. The only source of blowers that would fit into the available space is the imported car field. The Judson company makes a vane-type supercharger for the Volkswagen that could be very easilv adapted to a motorcvcle engine, and in England there are similar units available from Shorrock and Arnott. S COT. in Italy once manufactured a line of small Rootes-type blowers, and the MAG company in Switzerland was, and may still be, making a very nice blower of the same tvpc for the Volkswagen. A search of imported car agencies should unearth a supercharger of the proper size.

You will find that most of these superchargers are rigged for a belt drive, which is satisfactory but not as good as a chain. Apart from the fact that belt drives are not as efficient, and do not have the power transmitting capacity (at the same size and weight) as chain drives, there is also the problem of slippage due to inertia. Motorcycle engines gain revs very rapidly when the thottle is tweaked, and the inertia of the supercharger’s rotating elements may, in such conditions, cause the belt to slip quite badly. This can be the source of poor throttle response, and it is always a cause of rapid wearing of the drive belt. In the end a chain drive, although more difficult to rig because of the necessity for lubrication and oil-tight housings, will prove more satisfactory than any other. A gear drive would do the job magnificently, of course, but the long span that must, due to practical considerations, exist between the crankshaft and the blower means that either a long gear tower, or a shaft and 4 bevel gears would have to be employed — and that would be rather expensive, as it involves a lot of precision machine work as well as the cost of the gears themselves. Chain drive has the advantages of being positive, relatively cheap, and easily altered drive ratios.

We have been avoiding the question of supercharging two-stroke engines because the results of such an effort are so uncertain. All of the two-strokes used in motorcycles are crankcase scavenged, and if you force in air under pressure, you will be creating a pressure in the crankcase that will resist the pressure above the piston. If the boost pressure is very high, it will only serve to reduce power output. This would not be true if the pressure in the crankcase could be transferred up into the cylinder, but as the piston-port valve two-stroke has its exhaust port closing after the transfer ports close, any pressure in the cylinder would be lost. In some instances, when the two-stroke in question has poor breathing, or when the crankcase compression ratio is too low, a boost of 2 or 3 psi may have some beneficial effect, but even then the benefit — if there is any — will be purchased at great cost in fuel consumption. After all, during the transfer phase, the supercharger will be blowing mixture through the transfer ports and right out the exhaust.

We hope that, despite all the pit-falls we have mentioned, at least a few of our readers will give supercharging a try. If it is well done, it will do more to boost an engine’s output than all the jiggery-pokery with cams and compression that has ever been done. Ánd, if you are really greedy for power, you can do everything to the engine but raise its compression — and then add the supercharger. If you combine supercharging with the customary use of a lot of revolutions, the engine’s power will be increased well beyond anything that has been seen to date. ‘Way back in 1950, the supercharged BRM racing car had a 1500cc engine that developed 600 bhp, which is 400 bhp per liter of displacement. If one of our 650cc twins could be brought to the same level of output, it would deliver 260 bhp. There’s something to shoot for. •

View Full Issue

View Full Issue