TWO STROKES

Part One, A Foundation

BY GORDON H. JENNINGS

TWO-CYCLE ENGINES cannot be mentioned in any gathering of motorcycle enthusiasts without an immediate, and usually violent, argument ensuing. Pros and cons of every conceivable kind fly back and forth, and when all of the shouting is over, the question will not have been in the slightest way resolved.* Those arguing for the two-stroke will not have won over a single soul from the four-stroke camp — and it is unthinkable that anyone with a liking for the “ring-dings” would desert the cause. The situation among qualified engineers is very little different: a trifle more subdued perhaps, and with a great deal of esoteric terminology, but in the end the most persuasive arguments will have had no effect. Two-stroke fanciers will remain so, fourstrokers ditto, and never the twain shall find an area of agreement. The reason is simple: no one really knows, with any certainty, what does — or more often what does not — make a two-stroke run well. However, there are a few facts that stand out of the general darkness and these we will pass along in the hope that they will help the individual experimenter and/or casual arguer.

The great fascination for the two-stroke engine is that it, unlike the four-stroke, does not waste an entire revolution of the crankshaft between power strokes. The two-stroke fires every time around and should, on that prima facie evidence, produce twice as much power, at any given piston displacement, as the four-stroke. Moreover, in its less complicated forms it has no timing gears, camshafts, valves, oil pumps, or any of the incidental ironwork necessary in the four-stroke. Of course, behind this the matter is a bit more complicated, as we shall see.

Take, as a start, the unavoidable task of pumping the fresh charge into the cylinder and clearing the exhaust gases. The four-stroke engine does not do this very efficiently: the machinery used for the air-pumping work (the entire engine) is unduly heavy for the job at hand and friction losses are high. In fact, the pumping process alone is responsible for nearly half of the fourstroke engine’s total frictional losses.

With the two-stroke engine the situation is different — but not improved. It is possible, at a considerable expense in mechanical complication, to arrange for an external source of scavenging air — from, let us say, a lobe-type supercharger such as is used by GMC for their two-stroke truck engines. This system is mechanically efficient, but its inherent efficiency is overcome by the conditions under which it must fulfill. First, it must supply substantially more air than would be needed in a four-stroke engine for the same amount of power — up to 50% more. Secondly, owing to the two-stroke’s very brief “valving” periods it must pump the air through in a much reduced time and that requires yet more work. It is an inescapable fact that the pressure requirement will rise as the square of the speed, and the power needed to produce that pressure will go up as the cube of the speed. Hence the air-pumping work requirements of the two-stroke more than balance the frictional losses of the four-stroke and the former is, in the end, at a net disadvantage.

The average motorcycle two-stroke engine labors under the additional handicap of “crankcase” scavenging. In this system, the crankcase is sealed and its volume is carefully reduced so that the up and down motions of the piston produce sizeable pressure fluctuations. By valving the air into the crankcase when the piston is going up, and compressing it on the down-stroke, the crankcase is made to act as a scavenging pump. The system is beautiful in its simplicity, and involves little or no extra machinery and friction, but the volume of air pumped is too small, its density is reduced (to the great detriment of power output) by the heat from the piston and crankcase, and it makes virtually impossible the separation of lubricating oil and fuel.

This last disadvantage has been overcome by the simple and well-known expedient of mixing oil with the fuel. When this mixture is drawn into the crankcase, heat from the surrounding casing and mechanical elements evaporates the fuel, leaving the oil deposited on everything. Obviously, most of the oil will pass completely through the crankcase and into the cylinder, where it is burned with the fuel or left on the cylinder walls.

To the system’s credit it should be said that it eliminates many of the shortcomings of the recirculating, pressure-feed arrangement. Crankcase contamination, for example, is unknown and there is no such thing as an oil change; the entire oil supply changes constantly as the engine runs. Further, the cylinder walls are much better lubricated than isthe case with a four-stroke engine.

On the debit side, we should not overlook the fact that oil-mist lubrication does create some problems. For one thing, there is too little oil to permit the use of inexpensive “plain-metal” bearings in any but rather low output engines. Lacking the copious flow of heat-removing oil that is available with pressure-lubrication, the high-output, motorcycle two-stroke engine must have roller-type bearings.

In another area, there is the difficulty brought about by the presence of relatively large amounts of oil in the air/fuel mixture. Oil, unfortunately, has a very low octane rating and may precipitate detonation in high compression-ratio engines. Therefore, it is wise to limit, to whatever extent may be possible, the amount of oil mixed in with the engine’s fuel.

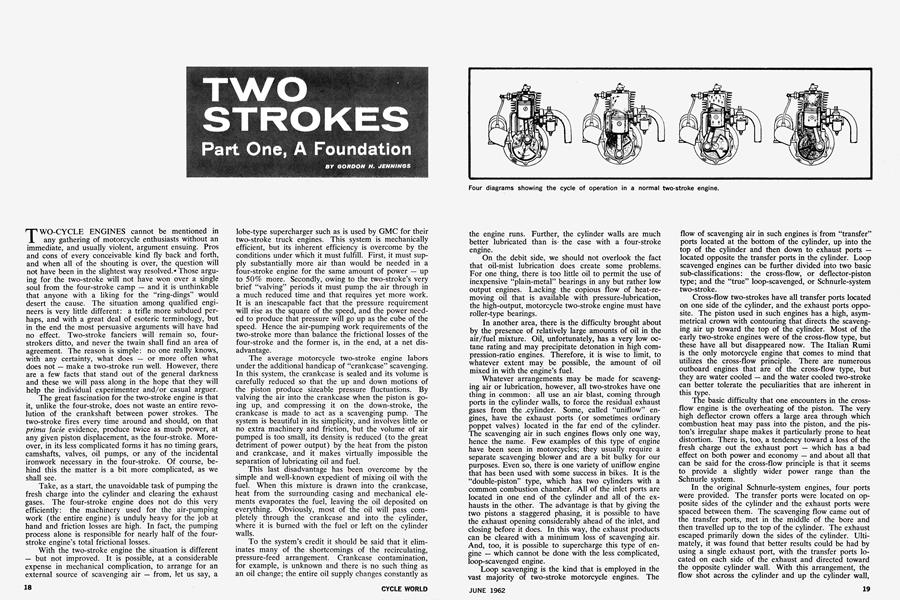

Whatever arrangements may be made for scavenging air or lubrication, however, all two-strokes have one thing in common: all use an air blast, coming through ports in the cylinder walls, to force the residual exhaust gases from the xylinder. Some, called “uniflow” engines, have the exhaust ports (or sometimes ordinary poppet valves) located in the far end of the cylinder. The scavenging air in such engines flows only one way, hence the name. Few examples of this type of engine have been seen in motorcycles; they usually require a separate scavenging blower and are a bit bulky for our purposes. Even so, there is one variety of uniflow engine that has been used with some success in bikes. It is the “double-piston” type, which has two cylinders with a common combustion chamber. All of the inlet ports are located in one end of the cylinder and all of the exhausts in the other. The advantage is that by giving the two pistons a staggered phasing, it is possible to have the exhaust opening considerably ahead of the inlet, and closing before it does. In this way, the exhaust products can be cleared with a minimum loss of scavenging air. And, too, it is possible to supercharge this type of engine — which cannot be done with the less complicated, loop-scavenged engine.

Loop scavenging is the kind that is employed in the vast majority of two-stroke motorcycle engines. The flow of scavenging air in such engines is from “transfer” ports located at the bottom of the cylinder, up into the top of the cylinder and then down to exhaust ports — located opposite the transfer ports in the cylinder. Loop scavenged engines can be further divided into two basic sub-classifications: the cross-flow, or deflector-piston type; and the “true” loop-scavenged, or Schnurle-system two-stroke.

Cross-flow two-strokes have all transfer ports located on one side of the cylinder, and the exhaust ports opposite. The piston used in such engines has a high, asymmetrical crown with contouring that directs the scavenging air up toward the top of the cylinder. Most of the early two-stroke engines were of the cross-flow type, but these have all but disappeared now. The Italian Rumi is the only motorcycle engine that comes to mind that utilizes the cross-flow principle. There are numerous outboard engines that are of the cross-flow type, but they are water cooled — and the water cooled two-stroke can better tolerate the peculiarities that are inherent in this type.

The basic difficulty that one encounters in the crossflow engine is the overheating of the piston. The very high deflector crown offers a large area through which combustion heat may pass into the piston, and the piston’s irregular shape makes it particularly prone to heat distortion. There is, too, a tendency toward a loss of the fresh charge out the exhaust port — which has a bad effect on both power and economy — and about all that can be said for the cross-flow principle is that it seems to provide a slightly wider power range than the Schnurle system.

In the original Schnurle-system engines, four ports were provided. The transfer ports were located on opposite sides of the cylinder and the exhaust ports were spaced between them. The scavenging flow came out of the transfer ports, met in the middle of the bore and then travelled up to the top of the cylinder. The exhaust escaped primarily down the sides of the cylinder. Ultimately, it was found that better results could be had by using a single exhaust port, with the transfer ports located on each side of the exhaust and directed toward the opposite cylinder wall. With this arrangement, the flow shot across the cylinder and up the cylinder wall, looping over and travelling down to sweep the exhaust products from the cylinder. In either form, a flat or slightly domed piston is used and the shapes of both piston and combustion chamber are considerably better, thermally, than is the case in cross-flow engines. Virtually all modern two-stroke motorcycle engines operate on the Schnurle principle.

We have been discussing the scavenging phase as though the intake and exhaust gases were completely separated — and they are, basically, in the four-stroke engine. This is, of course, not in absolute accord with the facts. The gas streams are separated to surprising extent, but there is some mixing during scavenging. Also, the very rapid rush of exhaust gases from the cylinder may cause the cylinder pressure to drop well below atmospheric and this can draw part of the exhaust back into the cylinder. Indeed, in practice some of the exhaust products always get mixed in with the fresh charge, and part of the charge is always lost out the exhaust port.

Most of the charge loss can be attributed to the symmetrical timing of two-stroke “valving.” It should be apparent that the “blowdown” phase, when the exhaust port is uncovered by the piston and the exhaust gases escape, must occur before the transfer ports are uncovered. Otherwise, the pressure in the cylinder (about 80 p.s.i. just before blowdown) would force exhaust gases back into the transfer ports and the engine would run poorly — if at all. Therefore, the exhaust port is always somewhat higher than the transfer ports and thus “opens” sooner. Unfortunately, it also closes later and that can allow an intolerable amount of the fresh charge to escape. This is one of the prime reasons for the fact that the two-stroke engine has so much difficulty matching the economy of the1 four-stroke. Much of the powerproducing mixture is lost out the exhaust before it can be burned and put to work.

Another inherent shortcoming of the two-stroke is the amount of working stroke that must be sacrificed to the porting. Time is required to get those gases moving and to get time, the tops of the ports have to be up reasonably high on the cylinder. Of course, area is important, too, and for that reason we want the ports to be as wide as possible. There are limits, however, on both height and width of the ports.

As we have said, the portion of the cylinder wall given to porting must be deducted from the working stroke. Thus, while raising the height of the ports gives more time in which blowdown and scavenging may take place, part of the effective piston displacement is lost. This occurs in the four-stroke engine too, but not to the same extent. In the four-stroke, not much more than 80 degrees of crank-angle will ever be taken from the working stroke; a relatively mild two-stroke, on the other hand, will surrender about double that amount. At first glance, it will seem that we are giving all that up for the benefit of the exhaust, as the exhaust port is always higher. The truth is that only 20 degrees or so of crank-angle are required, with the average port width, to allow the exhaust gases to escape and the pressure in the cylinder to drop to atmospheric. Consequently, if we were only concerned with the problem of getting the spent gases out, a narrow slot, barely above the piston at bottom center, would do the job very nicely. The problems of getting the fresh charge into the cylinder are much greater however, and it is really the transfer ports that make these inconvenient inroads into the working stroke.

In filling the cylinder, the main factor is time. Gases have mass, and inertia, and it takes time to set them moving. Because the pressure in the crankcase is not very high, we have a limited amount of force available to force the fresh charge in motion and there is an appreciable lag after the upper edge of the piston uncovers the transfer port before things really start moving. The lag is constant, in terms of time, and at high engine speeds the piston can flick open and then shut again before much of the fresh charge can travel into the cylinder. This is the effect that places such an abrupt “ceiling” on the speed range of the “touring-tuned” two-stroke.

Widening the ports will help to overcome the flow lag to some extent, by making it a bit easier for the gases to get through. But, in the end, the upper edge of the transfer port must be pushed upward if engine speed and power are to be increased very much. In any case, the gas-sealing rings on the piston place a sharp limit on the width of the port. Rings tend to bulge out into the port and if they do, they will be broken. Some engines avoid this by having ring-support bars in the middle of ports and, of course, most two-strokes have their piston rings “pinned” to prevent the ends of the rings from rotating around where they can spring out into the port openings.

The transfer passages between the crankcase and cylinder present some interesting problems, too. To be most effective they should be generous in area and have no sudden turns, but manufacturing convenience and cranckcase-volume requirements virtually assure that neither of these conditions will be met. Large passages add to the effective crankcase capacity and reduce the engine’s efficiency as a scavenging-air pump, so the transfer passages must be kept as small as possible — consistent with the requirements of cylinder charging. Commonly, the transfer passages will lead not from the crankcase to the cylinder, but from a point just under the piston. Indeed, some engines have windows cut in their piston skirts that permit the fresh charge to travel into short, curved transfer passages and into the cylinder with little increase in crankcase volume. This is an excellent method, but it complicates the manufacturing process and leaves the piston skirt either weaker, or heavier, than it would otherwise have to be.

While on the subject of pistons, it might be worth mentioning that here, too, the two-stroke differs considerably from the four-stroke. Basically, the two-stroke piston must be of slightly better stuff because it is subjected to a very heavy thermal (and some unusual mechanical) loadings. There is, after all, no cooling oil splattering against its underside, nor is there a “rest” period between firing strokes. Also, the exhaust gases escaping from the outlet port course down the side of the piston for a moment as the port opens, and the net effect of all this activity is to give the piston a good scorching.

Aluminum pistons having a tendency (well-known) to grow considerably under increased temperatures, it is necessary to provide an unhandy amount of initial, cold clearance to avoid seizing the piston when the engine is warm. As if this were not enough, neither the piston nor the cylinder expand evenly with heat. In fact, the piston will develop a distinct bulge on the hotter, exhaust-port side and this has in many cases forced the use of asymmetrical, “cam-turned” pistons. On some racing engines, even the exhaust-side clearance given by cam-turned pistons has proven to be inadequate. When this happens, the best means of providing the required local clearance is to deliberately seize the piston slightly, and then after removing it from the engine, file away a bit at the spots that are rubbing. After several trials, one will get a piston that is a terrible fit cold, but perfect (or nearly so) when warm. It is a technique worth remembering.

A large part of the problem with localized seizing of the piston does not originate in the piston at all. The presence of cast-in ports around the bottom of the cylinder causes the cylinder itself to assume some rather odd contours when hot — and the average two-stroke runs very hot. This condition is aggravated by the uncertain and unusually insufficient nature of air-cooling. It is no accident that many of the really outstanding examples of high-output two-strokes have been watercooled. That is the only type of cooling system that can be made to give absolute insurance against piston seizing under racing conditions. For less severe duty, however, air-cooling is more than adequate and is lighter and less bothersome — on a day-in, day-out basis — than water cooling.

Getting the fuel/air charge into the crankcase is a task that can be tackled from many angles. The method most often used is the piston-controlled “third-port” system, in which the intake port is uncovered by the piston skirt when the piston reaches top center. A pipe, or cast-on passage, leads from the carburetor to the port and when the port is uncovered by the piston-skirt, the vacuum in the crankcase draws in the mixture. This system has the considerable advantage of being effective and simple — but slightly better results may be had with other systems.

Most of the smaller American two-stroke engines use reed-type intake valves. These are simply a one-way valve formed by flat, thin, steel reeds that seat against holes on the inside of the crankcase. These allow the charge to enter the crankcase through the holes, but the reeds will drop closed if the flow tries to go the opposite direction. Reed valves take up too much space within the crankcase, and make it difficult to get the crankcase volume down, but they operate well over an exceptional speed range and are inexpensive. It is doubtful that they offer any advantage insofar as the racing motorcycle engine is concerned.

A better, but more complicated and expensive inlet system is provided by the rotary-valve. These can be incorporated into the crankshaft by having passages cast into the main journals that valve the mixture into the crankcase from a port in the main bearing. This type is good, but unless the main journals are made very large, it is impossible to get the valving passages up to an acceptable size. The disc-type rotary valve is more effective. These generally consist of a thin metal disc located at the end of the crankcase and driven by the crank. Part of the disc is trimmed away, and as the disc rotates, it covers and uncovers a hole that leads straight into the crankcase. This hole is, of course, fed a fuel/air mixture from an inlet pipe facing it across the disc-valve. In such systems, the “opening” ef the valve provides an absolutely straight path into the cylinder — which is certainly a feature worth having. To the best of our knowledge, only Yamaha offers this as a standard item on a mass-produced engine. Obviously though, the merits of the disc-type valve make it so attractive that there are probably others that make use of it as well.

Whatever method is used (apart from the reedvalve) to get the gases in and out of the cylinder, the quick-opening characteristics of the valves used in twostrokes will insure that there will be some substantial inertia effects present. The piston-controlled exhaust port, for example, opens so suddenly that all of the gases tend to leave the cylinder in a slug, and will actually create a vacuum by the quickness of their exit. The same effect is present, although in reverse, in the intake pipe. These are, in essence, the cause of the twostroke’s extreme noisiness: everything enters and leaves with a bang.

Even though the noisiness is a problem in touring engines, it can be converted into a real asset in racing. For example, the sudden inrush of mixture into the crankcase will get things moving so rapidly that after the crankcase is full, and no more vacuum exists to pull the mixture in, the sheer inertia of the gases in the inlet pipe will pack in a bit more. Then, if the piston closes the port quickly enough (or the rotary valve, for that matter) the "extra bit" will be trapped inside and we will have, in effect, a mild supercharging.

The exhaust is more complicated and less apt to be have agreeably. The outward rush of gases tend to clear the cylinder, and that is all to the good, but they try to drag a part of the fresh charge along - and that is bad. To combat this effect, a fantastic amount of experimentation has been, and is being done. Basically however, efforts may be divided into one of two classes.

The first, and to the casual experimenter the most promising exhaust system is the "diffusor", or mega phone type. In these, a short cone, which may be straight or curved, leads right out of the cylinder and into the air. Experimentation, of the cut-and-try variety, is the only thing that will give any answers. As a start ing point though, one might try a 14to 20-inch length, and an 8or 10-degree angle of divergence. Build a rough system, cut or lengthen until it works, and then make a prettier, more permanent system of the same size.

If you feel more ambitious, and are looking for a lot of practice in sheet-metal fabrication, there is always the expansion-chamber exhaust system. In these, the ex haust products are released into a diffusor, which ex tends into a closed chamber from which a very small pipe leads to the atmosphere. These systems stop the loss of the charge from the cylinder by (apparently) al lowing the gases to escape and then, as the chamber fills, there is a last-moment rise in pressure that traps the fresh charge inside the cylinder. The small end pipe then "leaks" off the pressure, getting it down to atmo spheric pressure before the next exhaust pulse occurs. Obviously, in the expansion chamber system the overall length and capacity of the chamber, the proportions of the diffusor section, and the diameter of the end-pipe are all critical. Experience with the type indicates that the chamber should have a volume of between 12 and 18 times that of the cylinder, and that the end will usually be about 50 percent smaller than the pipe at the port - but that is as much as we have been able to determine.

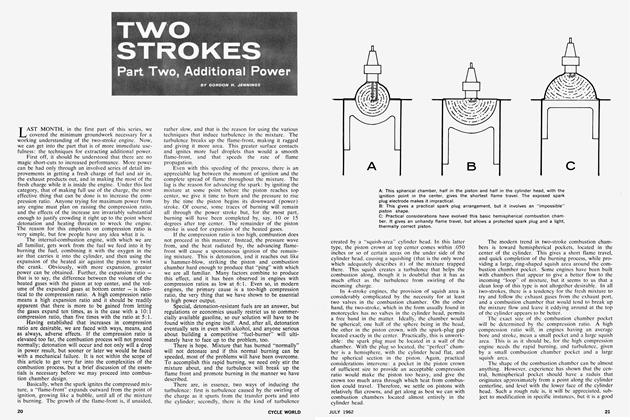

At the other end of the engine, in the combustion chamber, there is a design trend underway to give some "squish" effect between the piston crown and the cyl inder head as the piston reaches top center. This is done by providing a very small top center clearance around the edges, or at one side of, the piston crown. Where this reduced clearance exists, the mixture will be trapped as the piston comes to top center and literally squished, which stirs the mixture around and greatly aids combustion.

Considering the disadvantages we have listed, one might ask why anyone bothers with the two-stroke at all? It is, after all, a lot easier to get an acceptable amount of power and economy out of a four-stroke engine of the same displacement. The answer will vary, depending on the person giving the reasons but we think it is essentially that, dollar for dollar, the two-stroke can be a bit more powerful, and a lot more reliable. Re member, the racing two-stroke is very little more compli cated than the one that propels someone's scooter while the racing four-stroke takes all sorts of extra ironwork. And, too, the two-stroke is by nature relatively "idiot proof." Even with the all-out racing engine, it is usually possible to crank it up until the power fades without doing a bit of damage. The same tactics, applied to the four-stroke - would have valves dropping off or bend ing over in a very annoying and expensive manner.

Finally, the two-str6ke can, by hard work, be made to compete on a surprisingly equal basis with the best four-strokes - the exact techniques are a matter that will be taken up next month. •