CAMS AND VALVE TIMING

GORDON H. JENNINGS

AN ENGINE'S power and torque output characteristics can vary considerably, depending on its design features: bore and stroke ratio, intake and exhaust plumbing, compression ratio, etc. However, the most important single factor by far is valve timing. The same engine, with relatively minor changes in valve timing, can be made to thump along like a tractor; or to rev' furiously and deliver bags of horsepower. It is, unfortunately, impossible to have both sets of characteristics at the same time; one must be content with one or the other. And why is this? It might appear that if an engine has the breathing capacity for high-speed operation, it should certainly be able to perform well at low speeds. But, as most of us know, that is simply not the case.

Basically, the piston-type internal combustion engine's inherent lack of flexibility is caused by the inertia of air. Air has weight, so it takes time to set it in motion, and that is the source of all our difficulties. Let us consider what an engine could do if air had no inertia. The engine's intake valve could be opened at the beginning of the intake stroke, and closed as the piston reached bottom center. On the exhaust stroke, the exhaust valve could be opened at bottom center, and closed when the piston completed the exhaust stroke and stopped at top center. Lacking the property of inertia, the air would move in and out of the cylinder exactly with the motions of the piston, and there would be no lower or upper limit to operating speed.

Obviously, this very attractive situation can exist only in the imagination. Air, like all matter, does have inertia, and that complicates things. Add inertia to the situation just described and it changes entirely. The air would begin to pour into the cylinder slowly, and then faster and faster after the intake valve opened and the piston started down on the intake stroke. And, because of inertia, it would still be trying to pour in when the piston reached bottom center and the intake valve closed. Consequently, the cylinder would not be fully charged with air and full power could not be obtained.

Much the same thing would happen on the exhaust stroke. The air (actually heated air and various combustion products) would be delayed in starting out the exhaust pipe, due to inertia, and the exhaust valve would drop shut while some of the air was still trying to escape.

Early closing of the valves, both intake and exhaust, is actually doubly wasteful because it fails to use the inertia properties to help overcome some of the problems they cause. A column of air, moving in a pipe, will continue to move even after the force that started the motion is no longer present, and that can be a very useful property. For example, if we delay the closing of an engine's intake valve for some time after the end of the intake stroke, the s"heer inertia of the incoming air in the port and manifold will continue to pack in air for a time even though the piston has started back up on the compression stroke. Approximately the same occurs on the exhaust stroke, only in reverse. When the closing of the exhaust valve is delayed, the inertia of the gases rushing out the pipe will tend to drag yet more gases from the cylinder, and in many cases, the pressure in the cylinder will fall slightly below atmospheric.

If you think about it a while, the tendency for the outrushing exhaust gases to create a partial vacuum in the cylinder will suggest that the intake valve should be opened early — as indeed it should. When this is done, the departing exhaust gases will actually start the fresh air/fuel mixture flowing into the cylinder before the piston starts down on the intake stroke. Between this effect, and the tendency for the mixture to continue packing into the cylinder for a short time after the intake stroke, it is entirely possible to get a small "supercharging" of the cylinder. We have explained why it is necessary to open valves early, and close them late (relative to the motions of the piston in the intake and exhaust strokes). Now we can get to the question of "how much." The amount of early opening and late closing of the valves depends entirely on how fast the engine is to run. At very high crank speeds, it takes many more degrees before and after the intake and exhaust strokes to get the fresh mixture in the exhaust gases out. It is not at all unusual to have over 300-degrees of "duration" (the period during which the valve is open, expressed in degrees) in semiracing engines. "Overlap," the period during which both intake and exhaust valves are open, will usually be between 110and 115-degrees. By using enough duration and overlap, it is possible to obtain 100-percent volumetric efficiency (that is to say, fill the cylinder until atmospheric pressure is reached) at almost any engine speed. The point of maximum volumetric efficiency is always indicated by the engine's torque peak, and there are plenty of engines having torque peaks at crank speeds over 7000 rpm.

It would be nice if high-speed efficiency could be achieved without penalty in the lower speed ranges, but that cannot be. Should duration or overlap be extended too far, good low speed running is impossible. Moreover, even in a racing engine it is possible to carry these factors too far. As engine speed rises, the peaking speed for torque begins to creep closer to the peaking speed for horsepower, and the effective rpm-range is considerably narrowed. If the engine should happen to be driving through a 5 or 6 speed transmission, with closely staged ratios, the narrow power range can be accommodated and performance will be good. However, if for one reason or another it must drive through a 4-speed transmission, which will make it more difficult (perhaps even impossible) for the rider to hold the engine in its effective range, performance may be worse than that obtained with a similar engine having less peak power, but a long, flat power curve. As a matter of fact, it is that long, flat power curve most riders are talking about when they say that some particular motorcycle engine "has a lot of torque."

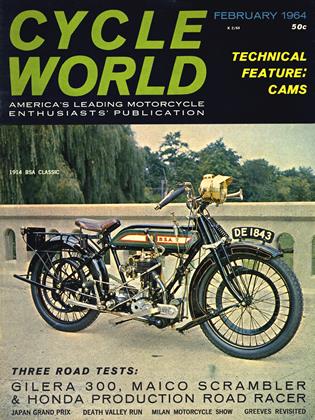

There are reasons for extending valve timing duration beyond those we have mentioned at this point. A valve has inertia, too, and cannot be opened or closed instantaneously. It has to be eased open, and then eased shut, and there are several degrees of crank rotation at each end of the valve opening period when the valve is ■so near its seat that there is very little flow past the valve head. Therefore, to get the valve opened far enough to be effective when the flow should start, it is customary to further advance the nominal point of opening. And, here again, engine speed has a great influence on the amount of advance opening — and closing, for that matter.

For any given rate of valve acceleration, it will be necessary to extend the total duration with increases in engine speed. For example, if we assume that with a valve gear of some given total mass and spring pressure it is possible to open the valve and close it within .010-second, then the total duration, in degrees, at 4000 rpm would be about 240-degrees. At twice that crank speed, 8000 rpm, to give the valve the same amount of time in which to open and close would require about 480-degrees. Obviously, it is not practical to extend duration that far; the engine would not run at any speed unless we "borrow" 150-degrees of crank-angle from both the preceding and following strokes, which leaves them with only 30-degrees in which to do what they were meant to do. So, we shorten the total duration, and take such measures as lightening the valve gear and installing heavier valve springs to keep the valve gear under control.

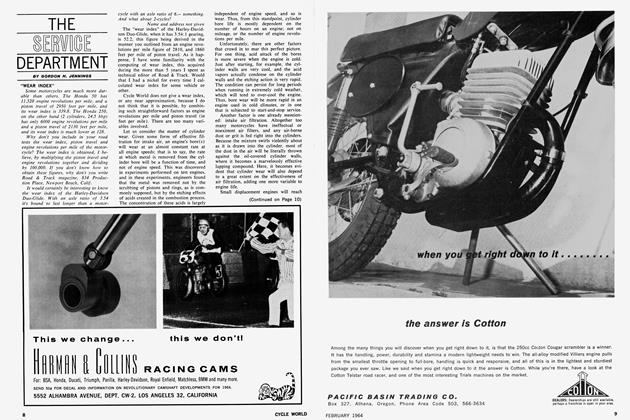

In practice, it is customary to use approximately 300-degrees of duration, for both intake and exhaust, and at 8000 rpm, that gives the cam designer about ,0063-second to open and close the valve. There is still another pair of factors to slip in here: total valve lift; and valve acceleration rates. Total lift should be between 20 and 25 percent of the valve head diameter to overcome flow restriction. In most valve and port layouts, the valve head offers no appreciable restriction to flow when it is opened a distance equal to about 1/4 of the valve diameter. For instance, in an engine with 1.5-inch intake valves, maximum flow values will be reached when the intake valve is opened .375-inch. From this, it would be easy to conclude that there is no point in opening the valve any farther — and that conclusion would be wrong.

Here, we get into the matter of opening and closing rates, which have fully as much effect on engine performance as duration. As we have said, an engine's valve gear has inertia, and cannot be opened and closed instantaneously. The entire valve gear — valve, cam follower, and in the case of most pass-produced engines, pushrod and rocker — has to be accelerated up to maximum opening rate, then slowed to a stop in the full-open position, and then accelerated again to the maximum closing rate, and finally slowed to a stop once more in the closed position.

Let us first consider the opening acceleration phase. The cam picks up the cam follower and starts accelerating it, and for a short time everything is rosy. We can safely accelerate the follower at .0010in/degrees2 forever, if necessary, and not overload anything. However, if we continue increasing the speed of the valve gear for much more than 30-degrees of crank angle, a lot of trouble will be in the offing. You see, from this point on, we have only the pressure of the valve spring(s) to control the valve gear, and it simply cannot handle very high acceleration rates. In fact, any and all valve acceleration that comes under the control of the springs should be no higher than about half that possible in the initial phase of valve opening, when the cam is forcing the valve open. So, after the initial approximately 30-degree period of acceleration, it will be necessary to start slowing the valve. Otherwise, so much speed may be built up that the follower will float completely clear of the cam lobe and may not make contact again until more than 200degrees later, when the nose of the cam has swung past. Then, after having been stopped at some point by spring pressure, the valve gear will pick up speed as it drops back toward the closed position, finally coming back to rest on the heel of the cam with a resounding crash.

To hold acceleration rates to an acceptable level, cams are ground to provide relatively slow opening and closing. However, by using heavy valve springs, it is possible to speed up the acceleration rates somewhat — and it is well worth doing if the parts are strong enough to stand the added loading. With high acceleration rates, it is possible to get the valve open farther, sooner, even with the same nominal duration, and that will improve breathing. This kind of acceleation is a characteristic of what is called a "high-lift" cam.

In most touring-type engines, the valves are opened far enough to give good breathing, but they do not open far enough, soon enough. High-lift racing cams, on the other hand, open the valve farther than is necessary, but by doing so, they get the valve open far enough to give good breathing very soon after lifting starts. This requires a violent acceleration rate for the first few degrees, after which the valve simply coasts out to a stop in the full open position. It would not be necessary to open the valve so far, but for the fact that the springs will not stop the valve any sooner, and it is essential that the cam follows the rest of the valve gear.

Some of the destructive effects of high acceleration rates on the valve gear can be reduced by using what is called an "opening ramp" between the heel and the lobe of the cam. This opening ramp, which gives about .0005-inch lift per degree, takes up clearance in the valve train slowly and then applies a pre-load so that most of the initial deflection will be taken up when the true acceleration period begins.

In touring-type engines, this opening ramp, or "quieting ramp" as it is also called, serves mostly to take up clearances gently, an prevents the valve gear from being too noisy, but it also serves a useful function in the racing engine. No valve gear is absolutely rigid, and the forces produced in pushing the valve open will flex pushrods and rockers to a surprising extent. Even in a pure racing engine, with cams directly over the valves, there is some deflection due to the slight stretching of the camshaft supports. Without the opening ramp to give a preload to the valve gear, there is a tendency for the entire valve gear to gather itself up like a spring and then bounce ahead of the cam. In practice, this appears as a sort of chattering motion of the follower on the cam, and when the cam profile is such that it excites the valve gear at its natural frequency, the chattering may reach such amplitude that it pounds the valve gear to pieces. The pounding will force the follower right through the film of oil between it and the cam, causing scuffing, and it can rattle the pushrod and rocker so badly that a failure occurs there, too.

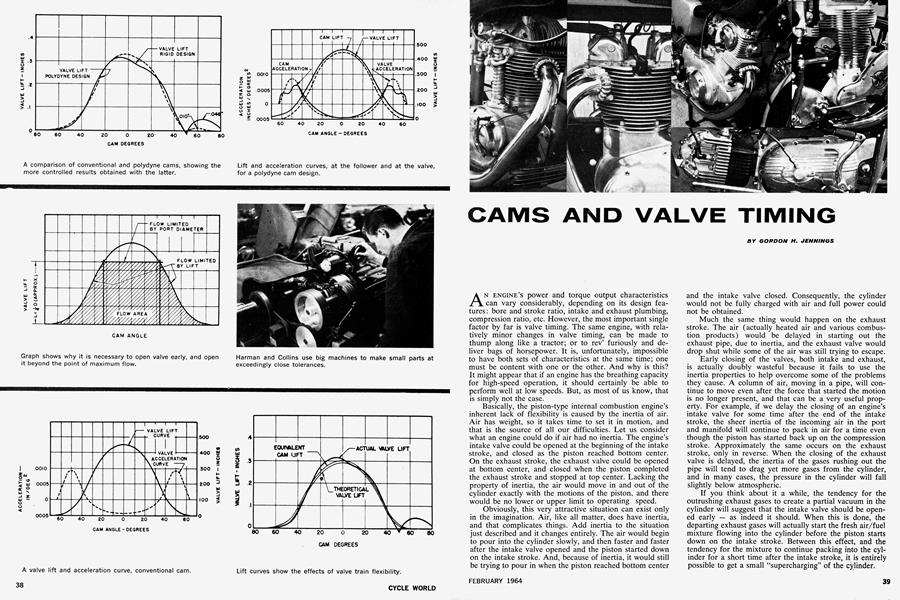

There is no substitute for the overhead camshaft layout, where there is nothing between the cam and the valve but a cam follower, but most of the world's engines have either a single overhead camshaft, with rockers serving both as followers and to transmit motions from the cam to the valve; or the conventional layout, which has followers, pushrods and rockers. In the latter instance, there are very substantial deflections under heavy acceleration, and it is necessary to deal with these if maximum power and reliability are to be achieved. To this end, engineers have devised what is called the "polydyne" cam. This cam is shaped so that the lift rate, at the follower, is adjusted to take into accounting the deflections through the entire valve gear. Consequently, the actual motions of the valve can be more closely controlled. With a polydyne cam, the follower is, in effect, vibrated out of phase with the rest of the valve gear, and while the accelerations applied at the follower may change several times through the course of one lifting cycle, the motion arrives at the valve smoothed-out by the flexing of the pushrod and rocker. Obviously, a system like this works well only over a fairly narrow speed range, but in practice it has been found that if the cam is contoured for some maximum speed, it will be satisfactory at any lower speed.

Even when a cam is not designed to take into accounting the flexibility of the valve train, it will always be designed so that it does not excite the valve springs at their natural frequency. If the initial valve acceleration period is extended too long, it will do this, and a great surging will be induced in the spring coils. Gary Robison, who heads Harman and Collins, has conducted many experiments with different cams, and he says that when the cam is exciting the valve springs at their natural frequency, the surging of the springs is strong enough to not only upset the valve gear, but to rattle the valve on and off of its seat as well.

Spring surging is the primary source of valve float, with modern cam designs. It is not too difficult to get a cam that will not actually float the entire valve gear, but it is difficult to stop the springs from surging at some point. For this reason, very stiff valve springs are used, partly because they are heavy enough to help control the valve gear, but mostly because they have such a high natural freauency that surging does not occur within the engine's normal speed range. The reason for using double valve springs is also to prevent surging. The inner and outer springs have different stiffnesses, and therefore different natural frequencies, and while one is surging, the other will be still doing its job. Of course, if the surging is severe enough in one spring, it may tend to "carry" the other with it.

Some control over spring surge can be provided by using spring dampers. These are usually flat steel spirals, that look like springs themselves, fitted between the inner and outer valve springs — or, if a single spring is used, fitted inside the spring. The valve spring coils scrub against this damper, and simple friction keeps the surging from becoming too serious. It is also possible, and very often done, to make the inner valve spring such a tight fit inside the outer spring, that the coils scrub together and offer a small measure of mutual damping action.

Dampers are all right, in a pinch, but they are better avoided if possible. There is a lot of heat built up in the scrubbing of the coils, and unless the springs are cooled in some way (air, oil, etc.) there will be a tendency for the springs to lose their tension. As a matter of fact, spring surge can cause problems with loss of tension even when no dampers are fitted. The spring material is "worked" so rapidly when surge occurs that the internal friction of the spring steel will cause a rapid heating of the springs. This might appear to be a small point; it is not. Robison reports that in his experiments with valve gear, he has noted that when the surge speed is reached, the lubricating oil around the valve springs will suddenly flash into smoke and, if the surge is maintained, the springs themselves will "blue" and lose their tension.

The roller-tappet cam offers some hope for getting very high acceleration rates without "float." A flat tappet will only take so much loading before it squeezes through the lubricating film of oil on the cam and begins to scuff; a roller is very much less affected by lubrication, and will take substantially higher loadings before a failure occurs. Therefore, the roller tappet can be subjected to extremely high spring and inertia loadings. In virtually all dragster engines, it has become common practice to use heavy springs at the valves, and an additional "helper" spring forcing the tappet down. Through such expedients, these engines, which have a valve-gear weight much greater than any motorcycle, are able to turn in excess of 8000 rpm without valve float. A few motorcycles are being fitted with roller tappets and helper springs, too, and when there is room inside the engine for the helper springs, or if the pushrods and rockers are strong enough to take the pressure from ultrastiff valve springs, the roller tappet setup is excellent.

The only thing wrong with roller tappets is that it is difficult to grind a cam profile that will give the high acceleration rates they are so well suited to withstanding. A flat tappet provides high acceleration rates simply because it is so wide that the lobe of the cam makes an early contact and literally levers the lifter upward. A roller, on the other hand, makes a point contact on the side of the cam lobe and is pushed upward in a sort of wedging action. Nonroller tappets, with a radiused face (like those in the Triumph, for example) give an action somewhere between that of the flat tappet and the roller. In fact, it is possible to increase valve acceleration rates simply by grinding a "flatter" radius on a radiused follower. Substituting a flatfaced follower would give the greatest increase in valve acceleration, but this can only be done where there is enough room to make the follower sufficiently wide. If the follower is too narrow, the lobe of the cam will dig into the edge of the follower. Increased valve acceleration can also be obtained by making the roller in a roller tappet larger in diameter. Unfortunately, it is not usually possible to make the roller enough larger to have much effect.

It would be nice if there was some nice, firm rule about what cam should be used with all engines. Unhappily, there is no such rule. The whole thing depends on too many different factors. First, there is the matter of matching timing and acceleration rates to the particular engine. Second, one must pick a cam that gives valve timing compatible with the job the engine has to do. A sports/touring enerjie must run fairly well at low speeds, and cannot have valve acceleration rates so high that the valve gear is pounded apart in a few hundred miles — a point that is relatively unimportant in a racing engine. Third, if the engine is to be used only for racing, it is still necessary to select a cam that will give maximum power (if the engine is to be used for road racing, in conjunction with a close-ratio transmission) or a wide spread of power and good torque (if the engine is to be used in speedway or TT racing).

The best way to get a camshaft suitable to your specific purpose is to write a cam grinder and outline what kind of engine setup is being used, and what kind of work the engine will be asked to do. Then, the cam grinder can recommend a cam that will be fairly near what is really needed. Do not write and tell him that you want a "3/4-race" cam for your Triumph Bonneville; there is no such thing as a 3/4race cam. Give him all of the particulars and let him tell you what cam and related equipment you need.

Even with the help of a good supplier, you will still have to do some experimenting. When you get into the final stages of engine development, a degree or two, one way or the other, will have its effect and you will be forced to try minor variations in timing to get the most from an engine. The process of discovery may run through a dozen or more camshafts, and it will be an expensive process. That is why the really good engine tuners are so reluctant to tell anyone exactly what they happen to be using. Their knowledge was gained the hard way, and they don't want to simply give it away. Most of them will talk all day about carburetion, compression, what pistons they like, and stuff like that, but mention camshafts and they become very secretive — which tells us a lot about the importance of the camshaft in the search for power. Certainly, we don't have any secrets to pass along; only the advice that the reader should follow the recommendations of some good, reputable cam grinder as a start — and then it's every man for himself.