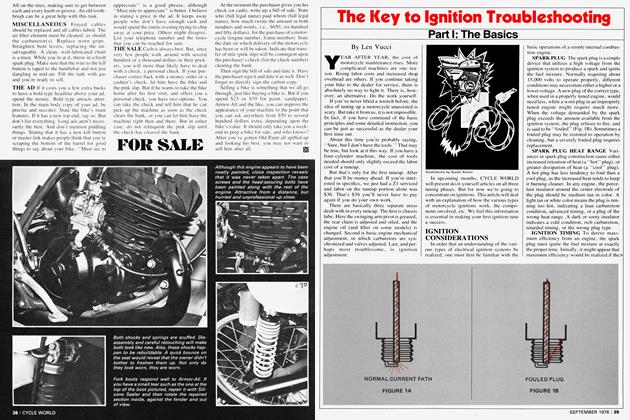

Dissecting the White Power Fork

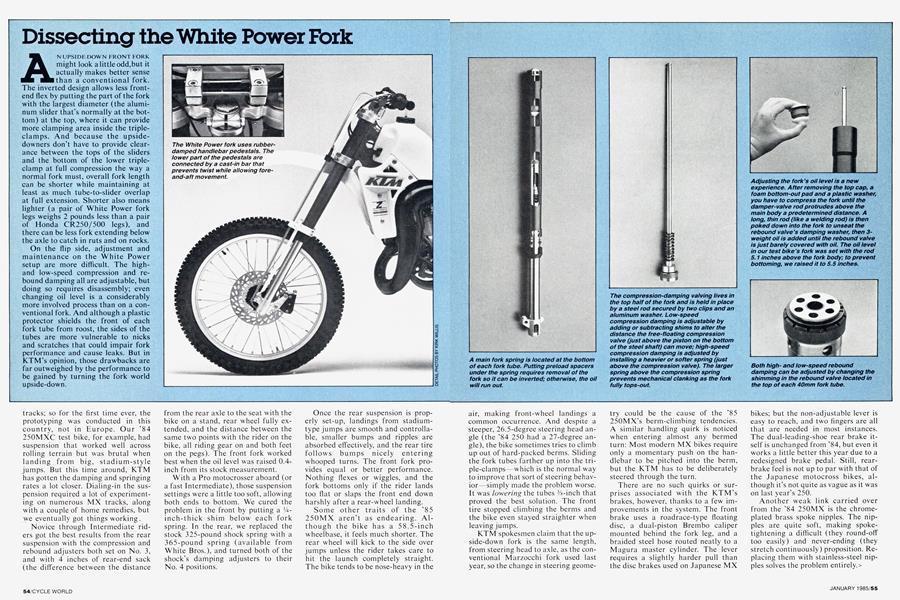

AN UPSIDE-DOWN FRONT FORK might look a little odd,but it actually makes better sense than a conventional fork. The inverted design allows less front-end flex by putting the part of the fork with the largest diameter (the aluminum slider that’s normally at the bottom) at the top, where it can provide more clamping area inside the triple-clamps. And because the upside-downers don’t have to provide clearance between the tops of the sliders and the bottom of the lower triple-clamp at full compression the way a normal fork must, overall fork length can be shorter while maintaining at least as much tube-to-slider overlap at full extension. Shorter also means lighter (a pair of White Power fork legs weighs 2 pounds less than a pair of Honda CR250/500 legs), and there can be less fork extending below the axle to catch in ruts and on rocks.

On the flip side, adjustment and maintenance on the White Power setup are more difficult. The highand low-speed compression and rebound damping all are adjustable, but doing so requires disassembly; even changing oil level is a considerably more involved process than on a conventional fork. And although a plastic protector shields the front of each fork tube from roost, the sides of the tubes are more vulnerable to nicks and scratches that could impair fork performance and cause leaks. But in KTM’s opinion, those drawbacks are far outweighed by the performance to be gained by turning the fork world upside-down.

View Full Issue

View Full Issue