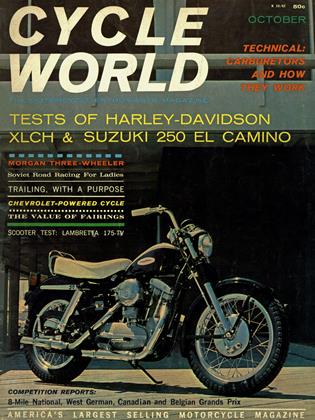

CARBURETION

. . . most meddled-with and least understood of all engine components.

GORDON H. JENNINGS

THE MOST MEDDLED-WITH and least understood of all the components that make up the motorcycle is the carburetor. When dealing with the carburetor, as when dealing with women, every man considers himself something of an expert — even though, in both cases, he is usually guided by not much more than instinct. And, in both cases, a little knowledge can be a very dangerous thing. We do not pretend to understand women; but we do know a thing or two about carbure -tion and we will pass this along.

Broadly speaking, a carburetor functions simply to combine fuel and air into a combustible mixture for the engine to burn. Moreover, most engines will bum air/ fuel mixtures ranging all the way from 6:1 to 22:1 — beyond those limits anything approaching normal combustion is extremely unlikely. In the past, these broad requirements have been satisfied by some really remarkable devices. We have seen engines running on fuel injected into the port from a hand-held squirt can, and some early carburetors were little more than a bit of pipe with a fuel-soaked wick inside. However, there is not much hope of achieving much in power output or efficiency unless some device operating at much closer mixture tolerances is employed.

While mixtures of gasoline fuel and air will burn over a wide range of mixture strengths, the chemicallycorrect mixture is one of approximately 15 parts of air to 1 of fuel, by weight. (Actually, for most fuels it will be closer to 14.8:1). A 15:1 mixture would, if given sufficient time and stirring, give complete burning and one might expect that this ratio would produce the highest power and economy. Unfortunately, it doesn’t quite work that way. You will note that we specified “sufficient time and stirring.” Therein, as they say, lies the rub. For a variety of reasons, there can never be enough time or stirring to bring together the last particle of fuel and the last particle of oxygen. Particularly toward the end of the combustion process, when the supply of uncombined particles is dwindling fast, it is hard to bring them together. For that reason, if we want to insure that all of the fuel will be burned, it will be necessary to provide a surplus of air. This will give those last particles of fuel a better chance of finding oxygen in the later stages of combustion. In most engines, about 15 percent of excess air will give the best utilization of fuel and, consequently, the best operating economy.

The exact opposite is true if we are interested in getting the highest power output. There is a limited supply of oxygen available in the cylinder, while fuel can easily be supplied in, relatively speaking, any amount. Thus, to obtain power, we must provide an excess of fuel to insure that all of the oxygen is used — even if it means losing some of it out the exhaust. Approximately 20 percent of excess fuel has been found to give the best results, generally.

In setting the mixture strength for either power or economy, it should be understood that — practically speaking — there are sharp limits to the amount that the mixture ratio may stray from the chemically correct 15:1. If the mixture goes too far in either the rich or lean direction (even though the engine continues to run without visible distress), the combustion process will be so badly delayed that much of the potential power goes out the exhaust valve. At the rich end of the mixture scale, fairly considerable errors can be accommodated without any penalty beyond excessive fuel consumption. Rich mixtures burn reasonably normal even with 60 percent of excess fuel and, while maximum power will not be realized from that kind of overfeeding, no damage will occur in the engine.

Lean mixtures, on the other hand, can bring about instant destruction. Combustion is very seriously delayed by a shortage of fuel, and the mixture will usually have just enough time to begin burning merrily when the exhaust valve opens. This subjects the exhaust valve to much higher flame temperatures and, coincidentally, oxygen that is ready to combine with anything — even steel — and the result is an overheated and burned valve. The piston comes in for its share of the grief, too: the stretching-out of combustion exposes the piston crown to fire for a longer time, and it may get hot enough to burn through. The one thing that a lean mixture does not do is increase the peak combustion temperature; it lowers it. The highest peak temperatures will most often be had at the mixture strength that produces the highest power output, but this mixture burns so readily that the time factor will be reduced and the piston and exhaust valve will be spared all that torture.

Few people are much interested in economy; most engine tuners concern themselves with power. However, it is worth mentioning that, as it is possible to over-do richness and actually lose power, so it is possible to get too far over on the lean side and suffer a loss of economy. At anything past the 15 percent of surplus air we mentioned eariler, the combustion will be affected to the extent that the drop in power will be greater than the savings in fuel, with the result that — in terms of bhp per hour — the engine will actually burn more fuel at an 18:1 air/fuel ratio than at 15:1. Reduced to the most practical terms, this means that you could easily install a smaller mainjet in your bike’s carburetor, and find that you were getting not only reduced performance, but fewer miles per gallon of gasoline.

From all this, one can see that it is not easy to find just the right mixture ratio. It is easy to determine the chemically correct ratio, but changes will have to be made to meet the requirements of different engines. Obviously, an engine with a lot of combustion chamber turbulence will require a much different mixture than one in which the mixture is relatively stagnant. And, the mixture strength will also have to be adjusted substantially to meet the requirements of high and low speed engines — time is a factor in combustion. In fact, not only will the mixture requirements change from one engine to another, but they will vary to some extent even with the same engine at different operating speeds, and under different loads. For reasons of economy, it is good if we can arrange for* the carburetor to deliver a slightly lean mixture when the engine is running fast under a light load — as when cruising at a steady speed. To get very close in satisfying all of these conflicting requirements, the carburetor must function in precise and complicated ways.

Before any choice of mixtures can be made with a new engine, development engineers establish an overall mixture requirement pattern. This is done in a purely cut-and-try fashion. The engine is put on a test stand, connected to a dynamometer, and fitted with a finelyadjustable special carburetor. The engine is then checked all through its speed range at, for example, 500 rpm increments; at each stage the engine speed is held steady by adjusting the load, and the mixture is adjusted with the throttle open wide. Readings are taken on a sensitive flow meter, and curves are established that show the relationship between specific fuel consumption, in terms of pounds of fuel per brake horsepower, per hour, and overall power output. The individual curves are then transferred to a larger graph, showing the full power and speed range, and are linked together to show an overall picture of the engine’s full throttle mixture requirements. Usually, this entire procedure will be repeated at several throttle openings; it is a time consuming process, but we know of no other way to do the job in as satisfactory a manner.

A typical single fuel consumption/power curve, starting up at the rich end of the scale, will lead forward — successive reductions in mixture strength increasing power output — until the point of maximum power is reached. Then, the output will begin to fall, passing the chemically correct point, and economy will, improve until the point of maximum economy is reached (in terms of fuel in, power out) and then further reductions in mixture strength will not only seriously reduce the power output, but operating economy as well. All this illustrates what we said earlier about the futility of going too big on the main jet in search of power, or too small for economy. Those who know what they are doing proceed very cautiously indeed.

Apart from the problem of mixture, there is the initial job of selecting the proper throat size — and this, while not as complicated or as filled with unpleasant possibilities — has been a major stumbling block for the amateur tuner. According to P. E. Irving, who designed the late versions of the famous Vincent V-twin and is an acknowledged authority in these matters, calculations for carburetor size may be based on a nominal air-flow velocity through the carburetor throat of 300 feet per second — this being the point of maximum torque. This velocity may be calculated, he states, by the formula:

.. S x 2 rpm D2 V =x -Lx — 12 60 d2

(D is the cylinder bore and d is the intake valve diameter, in inches; S is, of course, the stroke in inches.) More detailed information may be found in Irving’s book, “Motorcycle Engineering;” we suggest that anyone serious about advanced engine modifications obtain this text.

This method, expressed by the formula, has its value, but is somewhat limited in usefulness as it presupposes a fairly close initial guesstimation. Obviously, there is no point in selecting a throat size that would give a torque peak at 10,000 rpm if the engine in question will not turn more than 7500 rpm without breaking. Thus, some ground work in probable operating speeds will have to be done before starting calculations for carburetor size. For most engines, a nominal air flow speed at the valve head of 180 feet per second will give maximum torque, with maximum power at 260 feet per second. These values may be calculated using mean piston speed and the ratio of piston area to valve area — but these things were covered fairly completely in an eariler article (Valves and Porting, March 1962 Cycle World) and there is little point in re-covering that ground now. Those who are sufficiently interested in the theory may order that back issue from our circulation department.

From a purely practical viewpoint, one of the most satisfactory methods for selecting a carburetor throat size is to simply make a study of existing engines, with an eye toward power and torque characteristics that match those desired for one’s own engine. In other words, when squeezing a touring engine for racing level output, find a racing engine that is one of the same cylinder capacity and approximately the same valve timing, and then use a carburetor of similar size. If the touring engine in question has smaller valves than its racing counterpart, then the carburetor throat size should be reduced a like amount.

One factor that should not be overlooked in doing this is the need for flexibility. As the carburetor throat size is increased, the torque peak will be brought nearer the power peak, and both peaking points will be raised, causing a narrowing of the engine’s effective power range and a loss of flexibility. In road racing, and when using a close-ratio transmission, fairly drastic narrowing can be tolerated; but, for scrambles work, or any application where low speed torque is of some importance, do not try to use too large a throat.

Yet another point to remember is that two-strokes very often perform best when using a carburetor that is just right for a four-stroke engine of nearly twice the displacement. For example: a l-inch throat is just about right for a moderately high-output 250cc fourstroke; the same carburetor would also be a good choice for a 125cc two-stroke. This has nothing to do with the fact that the two-stroke’s induction pulses occur twice as often, at the same engine speed, as those of a four-stroke. It is, instead, due to the extremely short time of the two-stroke’s intake period. Actually, the carburetor is idle through most of a crank revolution; then, the entire charge is drawn through in a flash and if the carburetor throat is not of sufficient area, power output will suffer. Here is, we suspect, much of the cause for the high-performance two-stroke’s lack of flexibility: if power is not to fall off at high engine speeds, substantially the same volume of air must be drawn in as was the case at low speeds — but in a much reduced time.

To have a flow capacity equal to the high speed conditions, the carburetor must be so large that the air velocity through the throat will be too low to enable the carburetor to function effectively at low speed. This may be compensated to some extent when using a slidetype carburetor by simply not using full throttle at low speeds: the throttle slide when partly closed forms a reduced area venturi and will give somewhat better fuel atomization and more low speed power — even though the throttle is blocking the air flow. Unfortunately, all of this presupposes a greater degree of sensitivity on the part of the rider than most, in fact, possess. In the heat of battle, many riders will simply crank on full throttle and curse because the engine responds sluggishly.

Four-stroke engines behave much like the twostroke with regard to carburetor throat size; but not in so drastic a manner. They too have to move a lot of air in little time when turning fast, and a carburetor size that will permit the engine to get up full power must inevitably make it run a trifle raggedly at low speed. And, here again, the carburetor is to all intent idle much of the time — which is the reason that, very often, a two-cylinder engine (with more or less even intake pulses) will require substantially the same carburetor throat size whether one or two carburetors are being used. Indeed, the amateur who wants to convert his single-carburetor twin to a two-carburetor setup could do much worse than to simply add another carburetor exactly like the one his engine already has.

Any time a two-carburetor conversion job is done, some re-jetting will have to be planned for. Gasoline has a much greater inertia than air, and when using one carburetor per cylinder, we must take into accounting the high probability that the quickness of the intake pulses will upset the flow from the main jet. In a carburetor feeding two cylinders, the flow of air will be almost continuous and a steady flow of fuel will issue from the main jet; in the same carburetor, feeding a single, the fuel flow will be intermittent, and to get the total fuel flow needed to produce the right mixture, a larger main jet will almost certainly be required.

Two-strokes too will require a slightly larger main jet than a four-stroke of equivalent size; their very quick intake pulses and the effects of oil in the fuel account for this. The problem would be even more severe but for the acceleration well incorporated into most modern carburetors. An acceleration well is a space that holds a quantity of fuel between the main jet and the spray orifice. This is of special value when the throttle is snapped open; by having a dollop of fuel standing by, as it were, it is available instantly when the throttle opens and the inertia effects of the long column of fuel behind the main jet are avoided. Before the acceleration well has time to empty, fuel is beginning to flow through the main jet. This acceleration well also has the ability to compensate, to a great extent, for the uneven fuel flow produced by the sudden gulping of two-strokes and one-carburetor-per-cylinder racing engines.

Working with the main jet to provide the air/fuel mixture is the carburetor venturi. As most of you doubtless already know, air passing through a restricted orifice, a venturi, will create a partial vacuum, and it is this vacuum that draws fuel through the jet and into the airstream. Unfortunately, the proportion of fuel flow to air flow does not remain constant at all speeds. The rate of fuel flow increases faster than that of the air. Thus, any carburetor having only a venturi and main jet, without further compensating devices, would give the correct mixture strength only over a limited speed range: at lower speeds the mixture would be too lean; at higher speeds, it would be too rich.

In automotive-type carburetors, with butterfly throttles, the mixture balance is usually preserved by means of an air-bleed, which adds bubbles of air to the fuel drawn from the main jet in a proportion that increases with fuel flow. There is much to recommend this system: with it, combinations of main jets and air-bleeds can be selected to shape the mixture curve to suit any engine or any kind of operating conditions. Few motor-

cycles use this kind of carburetor, and the presence of a throttle butterfly makes it seem as though it would be less efficient than the slide-throttle carburetor. However, the butterfly can be used to get a wonderfully even progression from the idle jet to the main jet, with very smooth part-throttle running, and it would be a mistake to reject it just out of hand.

The vast majority of motorcycle carburetors, whether they are made in England, Germany, Italy, France, Japan or wherever, all follow fairly closely the slidethrottle Amal pattern. In these, a circular slide provides the throttling action, and also serves as a variable venturi when cruising at part throttle and low speeds. This tends to maintain the suction on the main jet at a somewhat constant level and thereby gives an even mixture (it says here in the fine print) at all speeds. Further mixture control, at small throttle openings, is provided by the effect of the cutaway on the forward edge of the throttle slide. The height of the cutaway controls the suction on the spray nozzle (and the main jet) up to about 1/2-throttle, after which it has little effect. Through the middle throttle opening range, the needle extending down into the spray nozzle does the job and at full throttle, the main jet takes over. Obviously, at full throttle the carburetor will function exactly as though none of those other controls existed and we are right back with the venturi and main jet — with all of the mixture problems we mentioned before. To cover this, all late-series Amáis — and most of the others — have some form of air-bleed as a compensating device.

GP and TT pattern carburetors of all makes usually have a control slide, set off to one side of the carburetor body, to control the air going to the air-bleed. Normally, this air control will be wide open, but for warming-up after a cold start the air-bleed will be sealed off. Also, the air control is very valuable in tuning: one may check for proper mixture by going flat-out and then easing -closed the air control. If the machine picks up speed, then the main jet is obviously too small; if it begins to fluff a bit and slow down, the main jet will at least be rich enough. That fact will be apparent, anyway, from the other signs of too-rich carburetion — a sooty exhaust and spark plugs, general lack of crispness, etc. If a good selection of jets is available, then one may just keep installing smaller ones until partially closing the air control does produce an increase in speed; then, go back to a slightly richer jet and you cannot be far from the optimum.

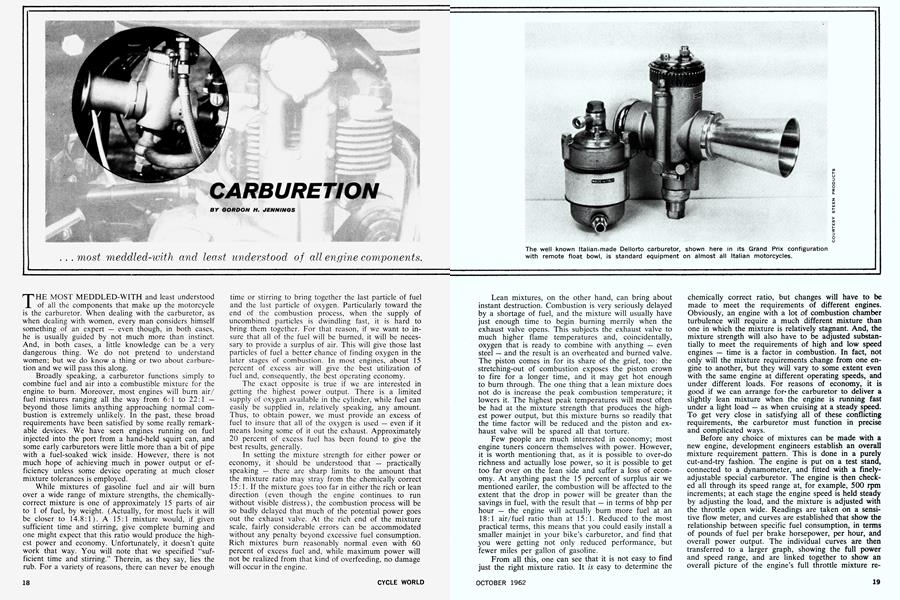

The choke slide found in ordinary touring-type carburetors can also be used to check mixture. Closing it slightly at high speed will make the mixture a bit richer. However, it also shuts the carburetor throat and this alone may cause a loss of speed — even though the mixture is perfect. Therefore, when embarking on a serious program of engine modification, buy a proper racing carburetor of either the GP or TT pattern. Both Amal and Dellorto carburetors are very fine instruments, for which vibration-free remote-float chambers can also be purchased, and their cost is more than balanced by the relative ease with which they can be tuned and the excellence of the results, in terms of power output, that can be obtained.

Alcohol fuels pose special carburetion problems. The chemically correct air/fuel ratio for alcohol is about 8:1, compared to the 15:1 proportions that are correct for gasoline, and a carburetor that is to handle alcohol will, therefore, need almost twice the fuel-flow capacity as would be required for gasoline. Keep all lines and passages big when working with alcohol or you may get into fuel starvation problems.

Alcohol fuel carries a large advantage to the speed tuner in its effect on errors in jetting. Because, relatively speaking, such large amounts are being fed into the engine, rather large quantitative errors may be made without getting outside the limits of good combustion. Another advantage is the higher specific heat of alcohol — this gives an evaporative cooling effect that produces a more dense charge in the cylinder and accounts, more than anything else, for the higher power obtainable with alcohol. The fuel, in itself, has no magic properties that give extra power. Indeed, if a normal touring engine were run on alcohol without the necessary changes in carburetion being made, it would develop less power and might even break down due to overheating from the toolean mixture.

Oxygen-bearing fuels, such as the well-known “nitro,” do give extra power — because they introduce extra oxygen into the cylinder. Very special tuning techniques are required for nitro: the oxygen is not released from the compound until it is subjected to considerable heat, and this tends to slow the combustion process. Unless a lot of work is done to get a radical ignition advance curve at high engine speeds, the nitro will go out the exhaust before it can break down into its useful components, and while one may get a significant improvement in torque, the peak power will not be changed all that much. And, finally, the presence of so much oxygen makes it difficult to get the mixture rich enough to avoid piston and/or valve burning. Unless you know what you’re doing, or are prepared to pay for experimental failures, it is best to avoid nitro altogether.

Specific carburetors and specific engines pose specific problems, and we have not even tried to give a step-by-step tuning-manual discourse here. For that, the manual dealing with the engine in question is the best guide. Generally, though, the information contained here will tend to turn the novice away from the more serious errors, and that is its purpose.

View Full Issue

View Full Issue

More From This Issue

-

Cycle Round Up

OCTOBER 1962 By Joe Parkhurst -

The Service Department

OCTOBER 1962 By Gordon H. Jennings -

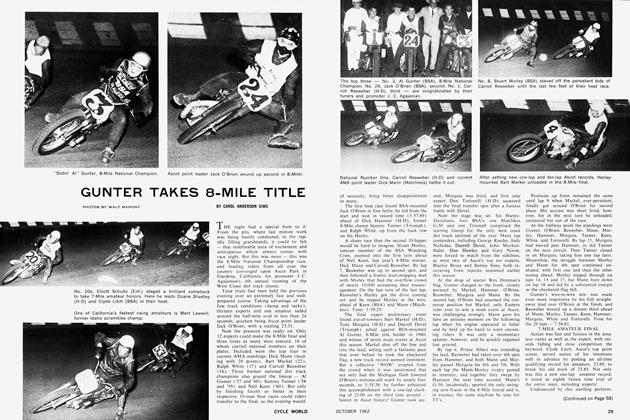

Gunter Takes 8-Mile Title

OCTOBER 1962 By Carol Anderson Sims -

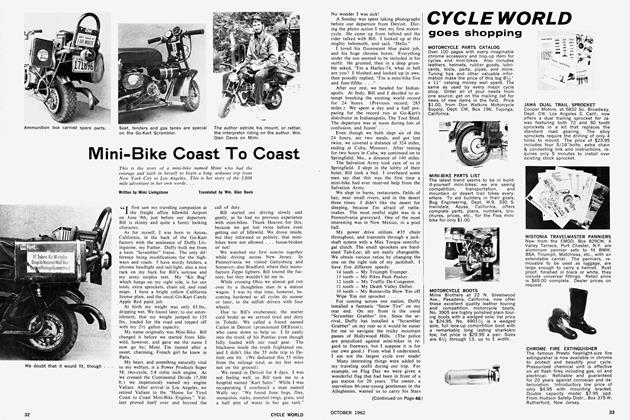

Mini-Bike Coast To Coast

OCTOBER 1962 By Mimi Livingstone -

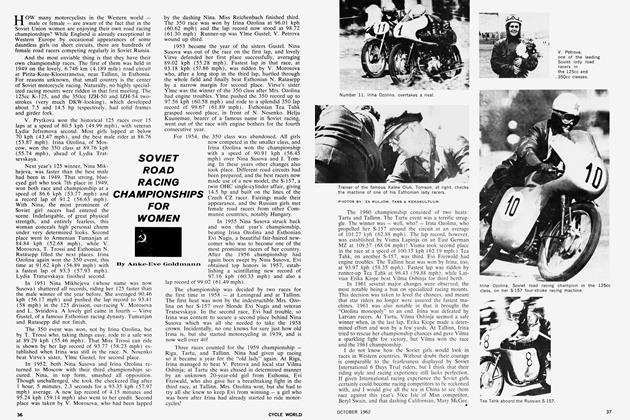

Soviet Road Racing Championships For Women

OCTOBER 1962 By Anke-Eve Goldmann -

Trailing, With A Purpose

OCTOBER 1962