VALVE FLOAT

THE SERVICE DEPARTMENT

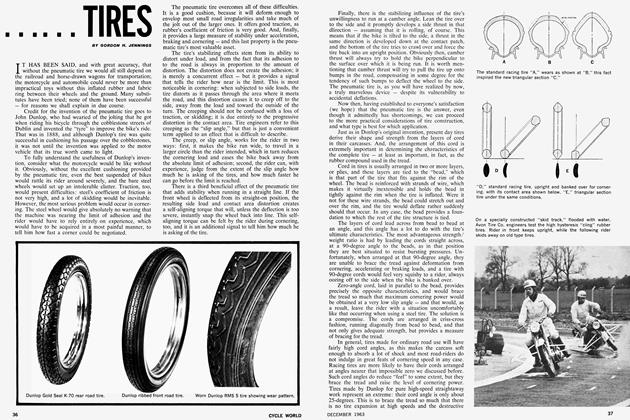

GORDON H. JENNINGS

A friend and I have had a rather long debate on whether a valve is bent on the opening or closing side of the cam. My friend contends that the valve is thrown into the piston; I say that at high rpm the valve does not have sufficient time to recover from its initial motion and is struck by the piston before it can close. My friend also says that "quarter-speed" cams were developed to cut down impact and so prevent valves from being thrown into the pistons. My theory is this would cut down on friction and prevent wear of the cam and follower.

Don Carron Peoria, Ill.

Given the right cam profile, either you or your friend could, conceivably, be right. However, insofar as the average cam is concerned, you seem to be a bit more right than he. Actually, it is appar ent that both of you are trying to over-

simplify a very complex problem.

In a highly-tuned engine with a hemi spherical combustion chamber and inclined valves (which grouping includes most motorcycle engines) the need for high compression ratios forces the use of a piston that is domed, and extends well into the combustion chamber when it is at the top of its stroke. Hence it comes very near the valves even when they are closed. The gap gets even smaller when the piston swings past top center between the exhaust and intake strokes: at that point, usually, both the intake and exhaust valves are open (this is the overlap per iod) and the clearance between the valve heads and the piston is exceedingly small. Thus, any interruption in the precisely timed motions of the valve will cause the piston to foul the valve head.

In some racing engines this contingency is anticipated by the designer and cared for by having small humps in the middle of the "valve-flats" on the piston head. Then, when valve-float occurs, the bumps on ttie piston contact the centers of the valve heads and simply drive them shut. Naturally, this should be considered as something of an emergency measure: pro longed pounding of the valves against the piston would surely cause some sort of mechanical failure. Even so, it is probably better than letting the piston strike the rim of the va1ve~ - which will often "clinch" the valve over, like a badly driven nail.

The real "truth" about valve-float, or bounce, as it is also called, is rather elu sive, and it may change character with

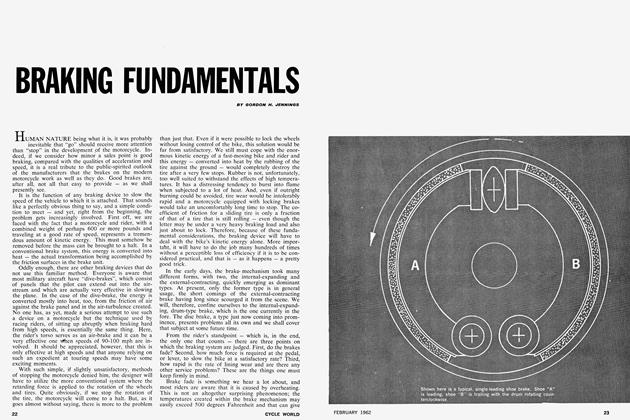

minor changes in cam profile. Basically, however, there are two causes of valvefloat: First, and by far the most common, is the floating brought about by surging of the valve springs. Every spring has a nat ural frequency, and when it is receiving a disturbing force "in phase" with that nat ural frequency, it vibrates wildly. Also, it is possible for the disturbing impulses to come at lower frequencies and still, by arriving in pulses that reinforce only (for example) positive waves, cause an ampli fying of the overall vibration. This holds true in the case of valve springs. All have a natural frequency, and when the mo tions of the valve (which are determined by the cam) reach a sympathetic fre quency, there is a tremendous surging of the valve spring. This surging will actual ly cause the valve to rattle on and off of its seat, and the rattling is audible -the source of the noise we associate with valve-float.

The second, and more rare, source of valve float is the actual inertial properties of the valve gear. The cam-follower, pushrod (if any) and the valve, are moved a short distance by the cam lobe, forcing the valve into its open position. That seems simple enough, but at the speeds involved (at a medium-high crank speed a valve opens and closes in 1/300 sec.) it becomes very difficult to do properly. The entire valve gear must start from rest, accelerate up to its maximum speed and then decelerate to a stop with the valve open. Then, hardly pausing at all, the valve gear is again accelerated up to a

(Continued on Page 50)

maximum speed and then slowed to a stop on the “heel” of the cam. If the acceleration phase on the opening side of the cam lobe is too high, the valve-gear will not follow the cam during the deceleration period. Approximately the same is true of the closing side: any attempt to close the valve too quickly will result in the cam lobe literally running out from under the valve gear. In both cases, the inertia of the valve gear overcomes the pressure from the valve springs. In the first instance, the valve may actually be thrown out beyond its normal full-open position and foul the piston. This is a very improbable thing though, as very few cams are ground with valve opening rates high enough to cause the “over-run” effect. Much more common is the other side of the problem: that of too-high closing rates. When this type of cam profile is used, one must always be very careful about over-revving the engine. Too fast, and the cams begin to outrun the rest of the valve gear. In most instances, the valve will “hang” open, unable to follow the cam, until it is struck by the piston. However, when the closing rate is made really fast — as it sometimes is in “accelerationgrind” cams — the cam lobe swings away from the follower so quickly that the valve is allowed to fall unchecked' until it hits its seat. Very much of this, and the stem will be pulled right out of the valve head, a failure that is usually blamed on “toc^-stiff” valve springs.

The cure for this is obvious: do not try to punch the valve open or let it drop shut too fast. Naturally, there is a bit more to the whole business than just that, but this is not the place to go into it.

Getting back to our resonant valve float, there are several techniques that have been used with great success. First, there are multiple valve springs; many engines use these — two or more coil springs, one inside the other — and each spring is of a different size, so that they do not resonate together. Occasionally, the coils will be wound to a size that permits them to rub slightly as the valve opens. This rubbing provides a certain amount of selfdamping effect that reduces the tendency to resonate. Along the same line of thought is the trick of placing a neoprene washer under the bottoms of the springs. Here, the high internal friction of the rubber partially damps out the resonance.

In point of fact, the whole subject is far too involved for discussion hère. All I can offer for the moment is an insight into the extent of the complications. I will not even begin to discuss the question of 1/4-speed cams. That will, with a more complete coverage of cam and valve gear design, be covered in some future article. Even so, to enable you and your friend to halt your argument, I would like to point out that, for a variety of reasons, the 1 /4-speed cam will reduce neither friction ppr wear, and may even increase both.

View Full Issue

View Full Issue