EFFICIENCY AND COMPLEXITY

IGNITION

TDC

IS ENERGY RECOVERY THE FUTURE OF MOTORCYCLES TOO?

KEVIN CAMERON

The last US steam locomotives were delivered 60 years ago.

Some 2,700 Liberty ships—rushed into production during WWII to overcome heavy shipping losses to German submarines—were also propelled by piston steam engines of a type that was antique even in the early 1940s. Locomotives and Liberty ships alike used steam at around 220 psi and 440 degrees Fahrenheit, so there was no need for heat-resistant materials such as are necessary in the exhaust valves of sparkignition gasoline engines.

When a locomotive started a io,ooo-ton train, it had to exert maximum force to heave such tremendous mass into motion. To do this, steam was admitted to the engine’s two double-acting power cylinders over the whole stroke of the pistons. As the train gathered speed, steam was admitted over less and less of the pistons’ stroke in order to increase efficiency. To see why this is, imagine a piston nearing the end of its stroke, with steam at full-boiler pressure still being admitted. When that cylinder’s exhaust valve slides open, all that lovely steam at full pressure is released—its energy wasted.

To prevent this loss, once the train is moving, a complex valve mechanism begins to stop the flow of steam to each cylinder earlier in the piston’s stroke. This boosts efficiency because it allows the steam to expand as the piston moves so that as steam cut-off takes place earlier and earlier, the pressure remaining at the end of the piston stroke becomes less and less. Once the train is moving at the desired speed, the engineer operating the locomotive moves the variable cut-off mechanism to supply steam for the shortest possible interval. With each cylinder receiving steam just long enough to keep the train moving at constant speed, this early steam cut-off boosts efficiency by allowing the steam being used to expand for most of each piston’s stroke so that there is

little energy left as that piston’s exhaust valve opens near the end of its stroke. An efficient heat engine process takes as much energy as possible out of the working fluid (in this case, steam) so that the minimum is wasted.

Let’s imagine we’ve decided to do our spring plowing with a rocket engine instead of with a tractor or team of horses. There would be no problem finding a small rocket motor capable of giving, say, 1,000 pounds of thrust to drive the plowshares through the soil. But think of the waste—the rocket exhaust is moving at thousands of feet per second, carrying away a fortune in wasted kinetic energy. Uneconomic amounts of fuel are burned in the process—hundreds of pounds per minute—which is an unaffordable waste. This is why a rocket motor becomes efficient only at high speeds comparable with its own exhaust velocity.

A spark-ignition gasoline engine is most like a steam engine operating on early cut-off. The piston rises toward top dead center, the ignition spark initiates combustion at perhaps 35 degrees before top dead center (BTDC), and the resulting heat release achieves peak combustion pressure of 1,000 to 1,200 psi by around 11 degrees ATDC. The hot, high-pressure gas above the piston is now the equivalent of a slug of steam that is valved into the cylinder near TDC, after which the steam valve closes.

In both cases—steam engine and internal combustion engine—maximum efficiency is achieved by allowing that high-pressure gas to expand against the moving piston, its pressure falling rapidly as the piston moves away from TDC.

Near the end of the stroke, this expansion process has allowed the hot gas to give up much of its energy pushing the piston. In a spark-ignition engine on full throttle, the remaining pressure is about 100 psi—only a tenth or less of its original pressure.

BY THE NUMBERS

60

PERCENT EFFICIENCY ATTAINED BY COMBINED-CYCLE ELECTRICITYGENERATING PLANTS

2009

THE YEAR KTM’S KINETIC ENERGY RECOVERY SYSTEM (KERS) WAS BANNED

80

TYPICAL RPM OF A DIRECT-DRIVE TWO-STROKE DIESEL MARINE ENGINE THAT POWERS OCEAN SHIPPING

In the case of those long-ago Liberty ship engines, the steam pressure remaining near the end of a piston stroke was high enough that a serious loss would be suffered if that steam were just exhausted to atmosphere. Therefore that cylinder’s exhaust steam was admitted to a second cylinder with a much larger bore, in which it expanded a second time, giving additional useful power. And then on into yet a third and even bigger steam cylinder, there to be expanded a third time before finally being exhausted to atmosphere. What kind of efficiency resulted from all this? Fuel consumption was roughly 0.83 pound of oil fuel per horsepower-hour. Had we generated the same power with a gasoline engine, the consumption would have been about 0.50 pound/ horsepower-hour or for diesel 0.35 pound/horsepower-hour.

Roughly one-third of the chemical energy of gasoline combustion

goes out the exhaust. Some of this can be recovered by a turbocharger. The highest evolution of the aircraft piston engine was the Wright Turbo-Compound 18 cylinder, which reduced fuel consumption to 0.42 pound/horsepower-hour, making direct flights from New York to London or Paris routine in the 1950s. Its exhaust energy drove three power turbines, which were geared back to the engine crankshaft, adding more than 300 hp during takeoff. Fuel economy was good, but maintenance was expensive and frequent.

In Formula One, hybrid power systems are now the rule, and turbochargers are coupled to electric motor-generators. To prevent turbo lag (power development delayed by the inertia of the turbine wheel), electric power from on-board storage is used to rapidly kick the turbo to boost rpm. When a waste gate would normally dump excess exhaust to atmo-

IN

FORMULA ONE, HYBRID POWER SYSTEMS ARE NOW THE RULE, AND TURBOCHARGERS ARE COUPLED TO ELECTRIC MOTORGENERATORS.

sphere to avoid over-boosting, now any excess turbine power is used to generate electricity that is returned to on-board storage.

Raising efficiency requires increased complexity in hardware and control technologies.

In combined-cycle electricitygenerating plants, a gas turbine provides most of the power but its exhaust heat raises steam to drive a steam turbine as well. Control is easy because such plants operate at constant rpm and load. Longdistance trucks, whose operation is closest to constant speed and load, are the next candidates for such energy-saving technologies. Will cars or even motorcycles follow with ever-more-complex energy recovery schemes?

History offers a caution. More efficient triple-expansion steam locos were built and tested, but their complexity and high parts counts made them costly and unreliable in rail service. CTil

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontRise of the Machine

October 2016 By Mark Hoyer -

Intake

IntakeIntake

October 2016 -

Ignition

IgnitionBrave New E-Shift World

October 2016 By Bradley Adams -

Ignition

IgnitionStreet Tire Talk Trial By Tire

October 2016 By John L. Stein -

Ignition

IgnitionThe Last of the Motorcyclists

October 2016 By Peter Jones -

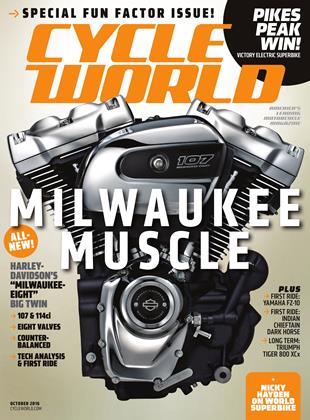

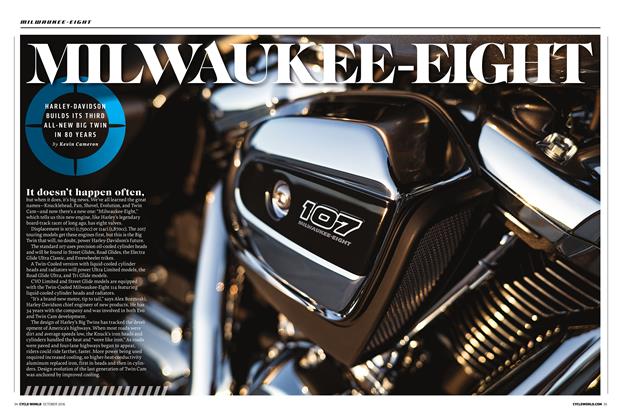

Milwaukee-Eight

October 2016 By Kevin Cameron