All Zeros

Why the inline-Six may be the perfect engine

BMW’S new K1600GT/GTL is powered by a transverse inline-Six—an engine design that is almost uniquely self-balancing. Pull out any engine-design reference material you like and look up the tables of primary and secondary vibration in vertical and horizontal directions. For an inline-Six, all the results are zero. Ditto for rocking couples— zero. Sixes are smooth. You’ll find some zeroes for inline-Fours, V-Fours and V-Sixes, but there are also either residual secondary shaking forces or rocking motions. But inline-Sixes come up all zeroes.

Another concern is what I call “propulsive smoothness.” If you’ve ridden Singles, you know that they push themselves along with a series of thuds. Twins are better, but especially at lower revs you can still feel the thuds through the driveline. In the auto biz, they have a special word for this combustion thudding—“chuggle.” When my fourcylinder economy-car engine gets down to 1350 rpm, its automatic transmission is programmed to shift down, not because it can’t pull at lower revs, but because the thuds are becoming noticeable. The more cylinders there are, the less “chuggle” there is.

Sport engines are usually revving high enough that propulsive smoothness isn’t an issue, but touring bikes, tuned as they are for strong bottom-end torque, tempt their riders to open the throttle at lower revs. That’s when a Twin or a Four begins to feel rough.

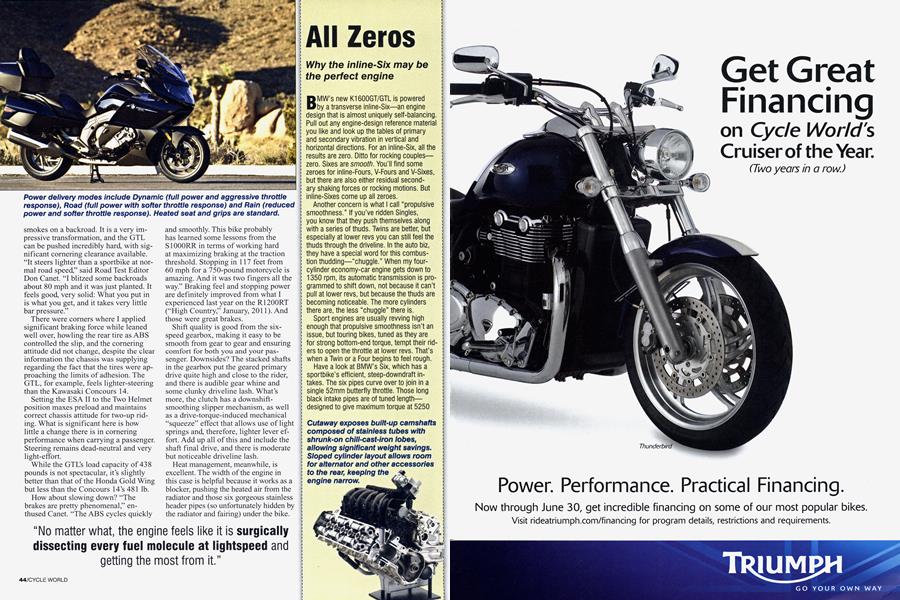

Flave a look at BMW’s Six, which has a sportbike’s efficient, steep-downdraft intakes. The six pipes curve over to join in a single 52mm butterfly throttle. Those long black intake pipes are of tuned length— designed to give maximum torque at 5250

The magic is in the motion, with the inline-Six self-cancelling vibration without the aid of balance shafts or other extra machinery. High compression, efficient combustion and a relatively small bore lead to excellent running characteristics.

rpm. In specific terms, that torque is just as powerful as in any highly tuned superbike but occurs at about half the rpm. Even down at 1500 rpm, the BMW’s 101-cubic-inch, 160-claimed-horsepower engine is already producing 71 percent of its peak torque.

With all that torque down so low on the rev scale, propulsive smoothness is important to basic comfort. Other makers try to smooth out thudding or shaking with tremendous flywheels or geared balance shafts, but an inline-Six is smooth in all departments—with zero extras.

Yet another point: An inline-Four with a flat crank stops all its pistons together every 180 degrees (one pair at Top Dead Center, the other at Bottom Dead Center). Pistons are as light as engineering can make them, but when all four of them must be started and stopped together, that generates its own form of unsmoothness, which engineers call “inertia torque.” In an inline-Six with 120-degree crankpin spacing, the pistons exchange energy with each other as they start and stop— not with the crankshaft. Zero inertia torque.

In 1900, Forest, a French engine company, built a Six for marine use, and Spyker in Holland made the first six-cylinder auto engine three years later—a 15-liter giant for the Paris-Madrid race. In 1963 Grand Prix races, Honda found its fabled 250cc Four overfaced by Yamaha’s rising two-stroke power. But how to package more smaller, higher-revving cylinders so that all could be equally air-cooled? Engineer Shoichiro Irimajiri drew a compact, narrow inline-Six that revved to 18,000 rpm. Playing upon that success, the 1978 Honda CBX became the first production inline-six-cylinder motorcycle engine, followed a year later by Kawasaki’s liquid-cooled KZ1300. BMW has a 95-year tradition of building smooth Sixes for aircraft and automobiles—and now for motorcycles. Kevin Cameron

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontA Japan In Need

JUNE 2011 By Mark Hoyer -

Roundup

RoundupAmerican Sport-Tourer

JUNE 2011 By Steve Anderson -

Roundup

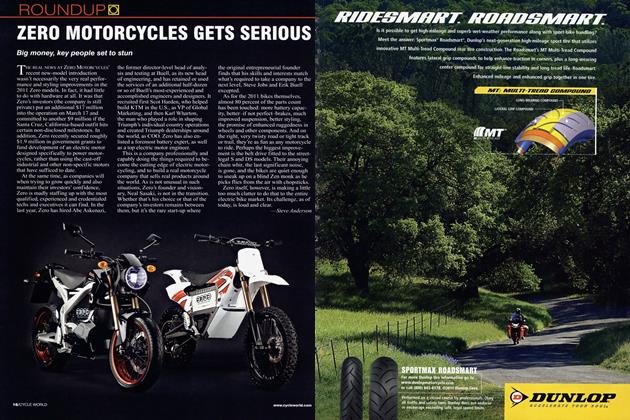

RoundupZero Motorcycles Gets Seriou

JUNE 2011 By Steve Anderson -

Roundup

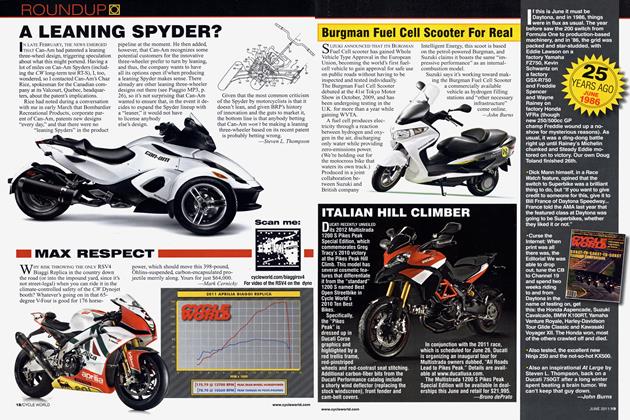

RoundupA Leaning Spyder?

JUNE 2011 By Steven L. Thompson -

Roundup

RoundupMax Respect

JUNE 2011 By Mark Cernicky -

Roundup

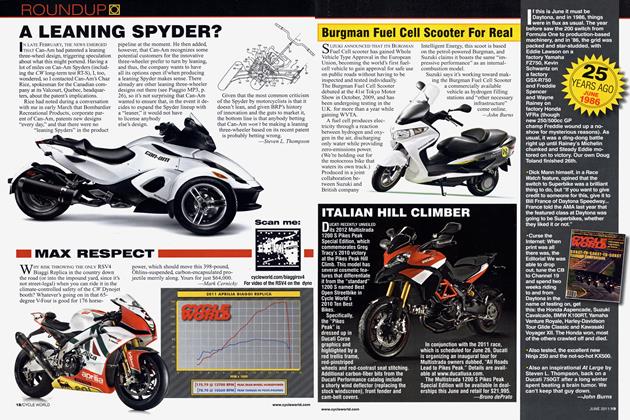

RoundupBurgman Fuel Cell Scooter For Real

JUNE 2011 By John Burns