Old Metal

TDC

KEVIN CAMERON

WHEN WORLD WAR I ENDED IN late 1918, aviation development, which had been progressing with extreme rapidity, came to a halt. World inventories of aircraft and engines were so large that near-scrap prices were being charged. In that climate, new ideas might have been interesting but they weren’t going to attract private investors.

Governments, always nervous about such things, took up the slack. In the U.S., at the Army’s air-development center at McCook Field in Dayton, Ohio, many of the nitty-gritty details of how to make high-performance engines reliable were being worked out.

Many engines built between 1900 and 1930 were given connecting rods with tubular shanks. This seems intuitively attractive because a tube is a light, stiff shape, easily machined. Early Wright engines had them, Guzzi Singles had them and Offenhauser race engines had them. Where are they today?

The easy answer is “in museums.” The problem was discovered at McCook Field, among other places, and it was very simple. How would you give the inside of the tube a smooth finish, free of crack-initiating scratches, tool marks or other defects? Careful analysis had revealed that when connecting rods broke, the failures usually originated at such surface irregularities. The traditional Hbeam connecting rod has all its surfaces on the outside where we can inspect and treat them, so it has survived.

It was likewise attractive to imagine valve springs made from hollow wire. The material near the center of a rod makes little contribution to strength (it has little “leverage” over any applied load, torsional or bending) but it does add weight. Weight reduces the natural frequency of the finished spring, making it vulnerable to engine-generated exciting forces. Wave motion can then build up in the spring, causing its force to vary and subjecting it to millions of excess stress cycles. This is what makes titanium attractive as a spring material— its density is only 60 percent that of steel, while its strength is nearly as high.

The answer to “why not hollow spring wire” is the same as with tubular-shank con-rods: There is no way to achieve a fatigue-resistant smooth finish inside the wire.

If we now look at ball and roller bearings, which are manufactured with extremely smooth surfaces, it would seem they should never fail from surface defects. Yet they do continue to fail. The answer to this conundrum is that the defects from which cracks originate in such perfect-looking parts are inside the material.

No steel is perfectly pure; it always contains elements other than iron and carbon. Aluminum and silicon oxides, and magnesium aluminum oxide all are present, and their molecules cluster together to form oxide inclusions. Any place inside a heavily loaded bearing ball or roller that is not steel is not carrying its share of the load, so such inclusions force stresses to pass around them. The result is zones of concentrated stress very like those that exist around surface scratches. A defect is a defect.

As stress cycling strains such regions, those atomic bonds that happen to be most highly stressed have the highest chance of being broken—and some break at every stress cycle. Thus, the material “remembers” what has been done to it and is moved some way along the road that leads to eventual failure.

In the 1960s, several of us in the Boston area had early Yamaha TD1B and -C 250cc roadracers. We soon learned that if a new bike had not broken its engine mounts by the end of its first season, it soon would. These were two-stroke, 180-degree parallel-Twins and had vigorous rocking couples that the frame and engine mounts had to resist by sheer strength. We came to call this inevitability of cracking “old metal.” The frame might look perfect— even the paint could be perfect—but inside the metal, some kind of irreversible damage had been done. Those who could afford it (I was not one) replaced their bikes every year. The others would soon notice a “different feeling” and discover a broken engine mount.

Fatigue cracking is also temperaturedependent. As engine rpm rose, connecting-rod rollers began to skid from their own inertia rather than to track the normal plus-and-minus 25 percent speed change of the crankpin bearing. At first, smaller, lighter rollers and ingeniously lightened cages kept this at bay—there was again enough “traction” from the load to make the rollers roll. Another palliative was to make the rollers of more temperature-tolerant tool steels. But eventually, such remedies had gone as far as they could. As bearing temperatures rose, failures again appeared ahead of schedule. No rider can accept a mechanical DNF. Riders racing Aprilias in those days were forever awaiting the latest big-end update, which was supposed to make it possible to operate above 13,000 rpm reliably.

Honda, and perhaps others, took a new direction—ceramic rollers made of silicon nitride, a material generally unimpressed by temperature. Being essentially stone, these had very low density near 3.2 (steel is 7.8) and so were further protected against inertial skidding. And if they did skid, they shrugged off the resulting temperature. As our Team Hansen technician Mr. Yoshida liked to say back in the day, “No more trouble again.” But crankshaft price was now $50,000. It’s not cheap to keep cracking and failure at bay.

Back in the early 1950s, the Mercedes W196 GP car had a StraightEight engine with center drive, built up from many pieces assembled with radial-face splines and internal bolts. Why such complexity? To allow use of robust one-piece rods and big-end roller cages! Even mighty Mercedes couldn’t afford frequent replacement of these fiendishly machined beauties, so they were disassembled and crack-inspected by magnetic particle (Magnaflux) after every event, then laboriously reassembled.

The need for similar detailed and exhaustive inspections is what transformed the Space Shuttle program from its optimistically planned 50-60 flights per year to one-tenth of that. Some technical situations just turn out to be very time-consuming to make reliable. “Old metal” must be detected before it can cause failure! □

View Full Issue

View Full Issue

More From This Issue

-

Up Front

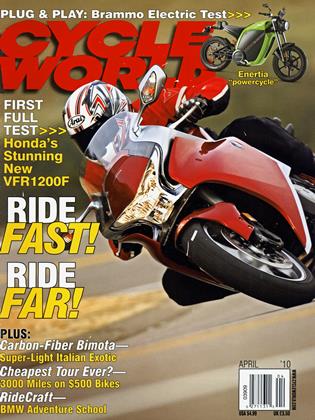

Up FrontBike of the Year

April 2010 By Mark Hoyer -

Roundup

RoundupMeet the Motus

April 2010 By Kevin Cameron -

Roundup

RoundupSuperbike For the Common Man?

April 2010 By Blake Conner -

Roundup

RoundupRide Like Rossi

April 2010 By Blake Conner -

Roundup

Roundup25 Years Ago April 1985

April 2010 By Mark Cernicky -

Roundup

RoundupEtc...

April 2010